Crystal-granular sweetener for dining, and preparation method thereof

A granular sweetener technology, applied in food preparation, application, food science, etc., can solve the problems of poor tolerance of fillers, uneven appearance, poor flow performance, etc., and achieve less adhesion and convenient long-term Time preservation and long-distance transportation, the effect of ensuring sweetness and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

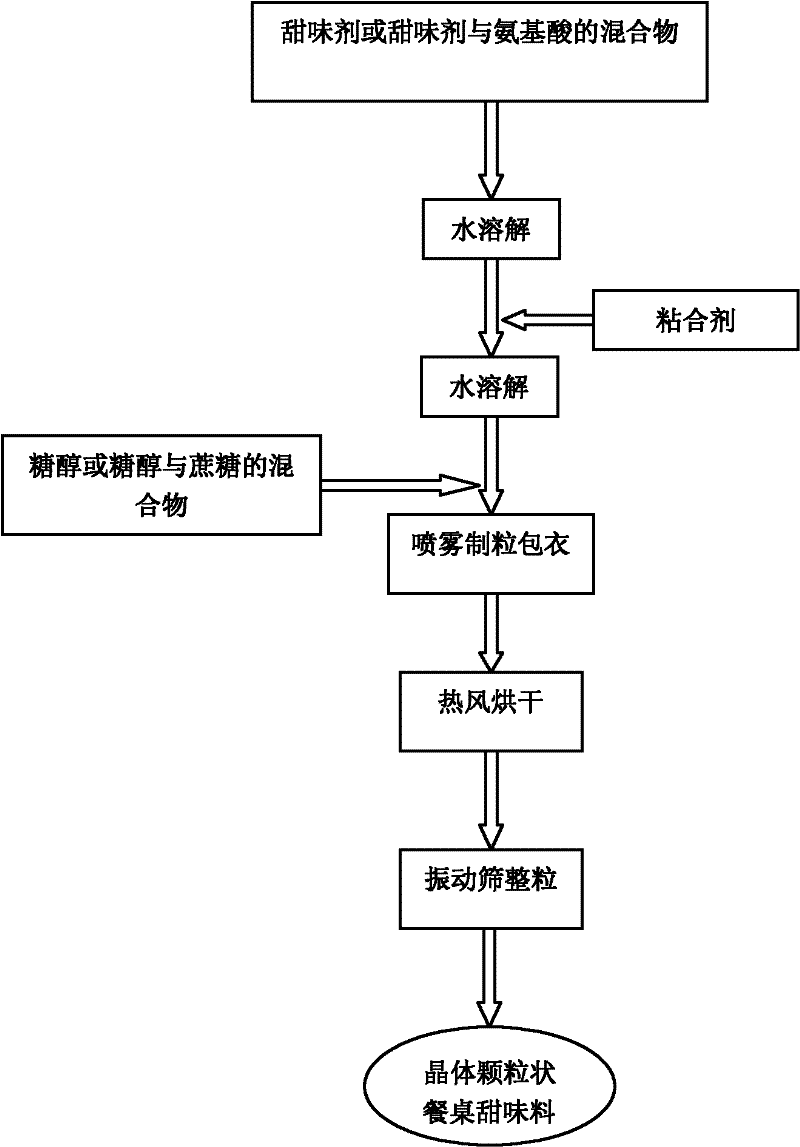

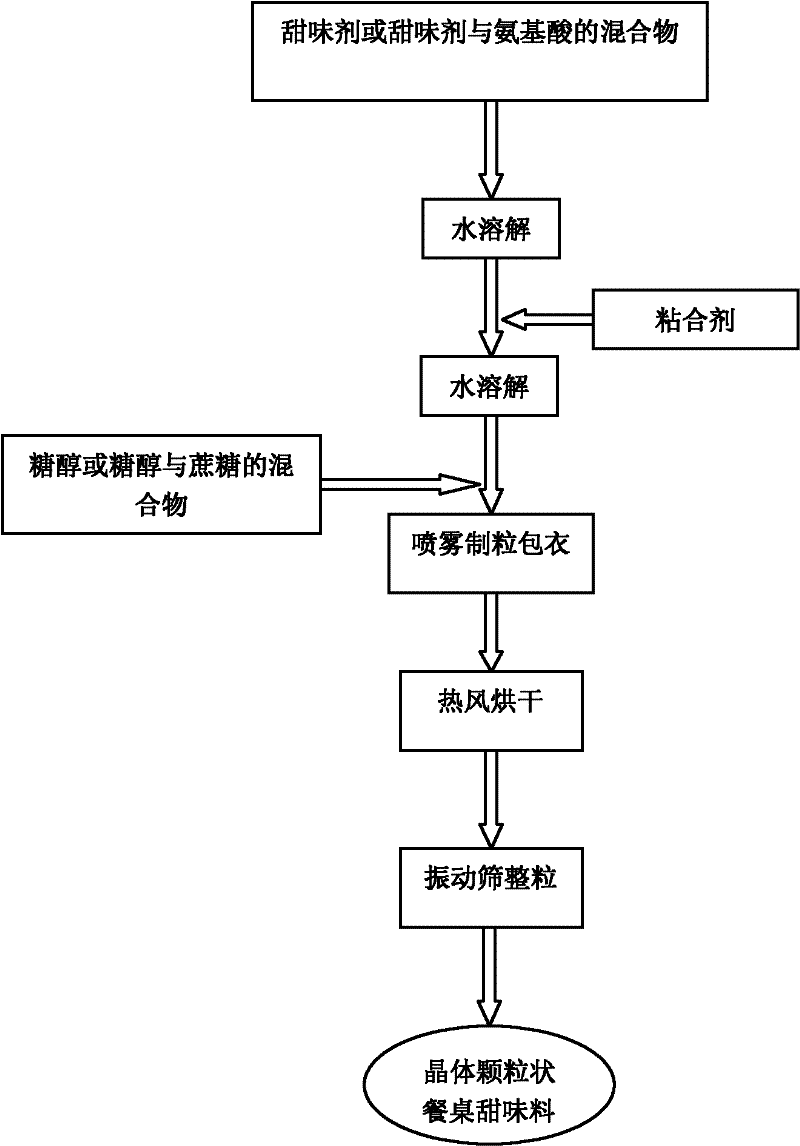

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 0.1kg of acesulfame-K, 0.2kg of sucralose, 0.1kg of aspartame, and 0.1kg of alanine in 3kg of purified water, heat to 90°C for 10 minutes, then cool to room temperature; then add 0.09kg of oxymetholone Base cellulose sodium, after stirring to make it completely dissolved, transfer the above mixed solution into the container as a coating solution for subsequent use; add 15kg of xylitol and 14.41kg of erythritol to the selected particle size of 20-30 mesh In the fluidized bed of the fluidized granulation coating equipment, the working pressure is 0.2-0.3 Pa, and the working temperature is 50-60°C. The spare coating solution is sprayed into the fluidized bed through the pump, so that the mixed solution is evenly sprayed and coated. On the surface of the sugar alcohol granules, the granules are dried by hot air, sized by a vibrating sieve, and packed. This gives 30 kg of crystalline granular table sweetener having a sweetness 6 times the theoretical sweetness.

Embodiment 2

[0040]Dissolve 0.36kg of sucralose in 3kg of deionized water in advance, heat to 100°C for 5 minutes, then cool to room temperature; then add 0.08kg of gum arabic and 0.02kg of xanthan gum, stir to dissolve them completely, and mix the above mixed solution Transfer it into the container as a coating solution for later use; add 29.54 kg of erythritol with a selected particle size of 30 to 40 mesh into the fluidized bed of the fluidized granulation coating equipment, and the working pressure is 0.5 to 0.6 Pa. The temperature is 70-80°C, and the spare coating solution is sprayed into the fluidized bed through a pump, so that the mixed solution is evenly sprayed and coated on the surface of the sugar alcohol particles, dried by hot air and sized by a vibrating screen, and packaged. This gives 30 kg of crystalline granular table sweetener having a sweetness 8 times the theoretical sweetness.

Embodiment 3

[0042] Dissolve 0.1kg of acesulfame-K, 0.1kg of aspartame, 0.002kg of neotame, 0.07kg of mogroside, and 0.083kg of sucralose in 3kg of membrane-filtered pure water, heat to 95°C for 15 minutes, then cool to room temperature; then add 0.12kg of hydroxypropyl methylcellulose, stir to dissolve it completely, transfer the above mixed solution into a container as a coating solution for later use; add 10kg of erythrose with a selected particle size of 30-50 mesh Add alcohol, 10kg isomaltulose, 5kg D-mannitol, and 4.525kg sucrose into the fluidized bed of the fluidized granulation coating equipment, the working pressure is 0.8-0.9 Pa, and the working temperature is 40-45°C. The standby coating solution is sprayed into the fluidized bed through the pump, so that the mixed solution is evenly sprayed and coated on the surface of the sugar alcohol particles, dried by hot air and sized by vibrating sieve, and packed. This gives 30 kg of crystalline granular table sweetener having a sweetn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com