Detection method of early autogenous shrinkage of cement mortar

A technology of cement mortar and detection method, which is applied in the direction of material inspection products, etc., to achieve the effects of improving accuracy, easy-to-obtain test equipment, and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

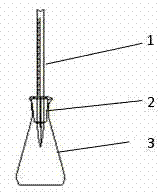

[0026] Such as figure 1 As shown, the detection device is composed of a graduated dropper 1, a bottle stopper 2 and an Erlenmeyer flask 3, and the bottle stopper 2 and the well-sealed Erlenmeyer flask 3 form a whole. A graduated dropper 1 forms a tight connection with the bottle stopper 2 of the Erlenmeyer flask, and forms a sealed system with the Erlenmeyer flask 3 . First, thoroughly clean the device, dry it and check the tightness, and soak the inside of the device with oil before use. Mix cement mortar according to the mixing ratio in Table 1, weigh 100g of the prepared cement mortar, put it into a conical flask with a capacity of 100mL, a wall thickness of 1mm, and glass material, and fill it up with oil to ensure that there are no air bubbles in the bottle. After corking the cork, add the oil level of the graduated dropper with a maximum volume of 1mL to the 0 mark. Read the reading of the scale tube at this time and record the time, and place it at a temperature of 2...

Embodiment 2

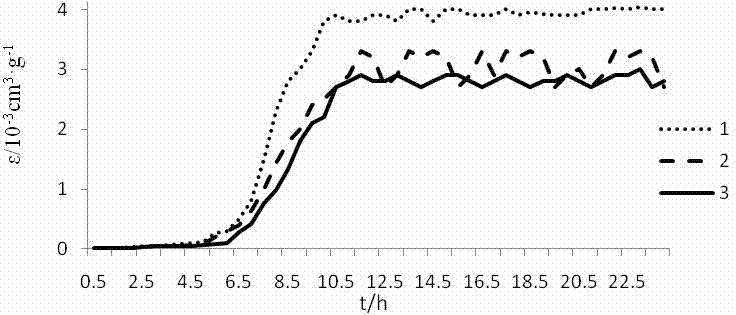

[0030] The test method is consistent with that of Example 1, the difference from Example 1 is that the mixing ratio of cement mortar is different, the fly ash is replaced with silica fume, and a water reducer is added. For example Table 2, the quality of the cement mortar tested in this example is 250g, and this device with a capacity of 200mL and a wall thickness of 5mm is used, and the sample is cured at a temperature of 20°C to 25°C. Test data such as image 3 .

[0031] Numbering

[0032] *% of mass of cementitious material

Embodiment 3

[0034] The difference from Example 1 is that the mix ratio of cement mortar is different. By trying to prepare more mortars with low water-cement ratio, the influence of different water-cement ratios on the early self-shrinkage of cement mortar is studied. With example image 3 . In this example, the quality of the cement mortar detected is 500g, and the device with a capacity of 500mL and a wall thickness of 3mm is cast iron. The maximum measuring range of the graduated dropper is 10mL, and the sample is placed at a temperature of 20°C to 25°C. maintenance. Test data such as Figure 4 .

[0035] Numbering

[0036] *% of mass of cementitious material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com