Method for detecting self-constriction of cement-based material

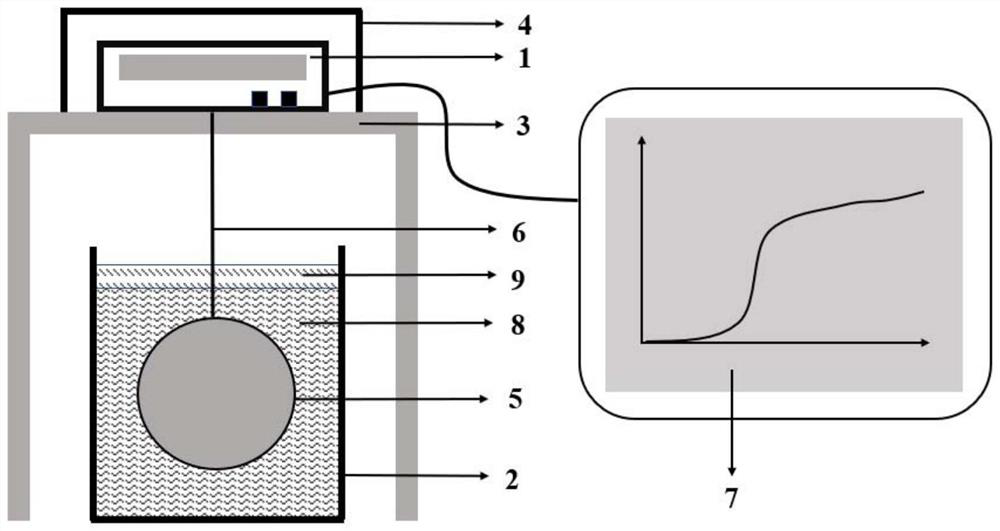

A technology of cement-based materials and detection methods, which is applied in the directions of material weighing, material analysis, and measuring devices, which can solve the problems of low precision of measuring devices and difficulties in implementing volumetric methods, so as to achieve accurate and reliable experimental data, reduce adverse effects, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

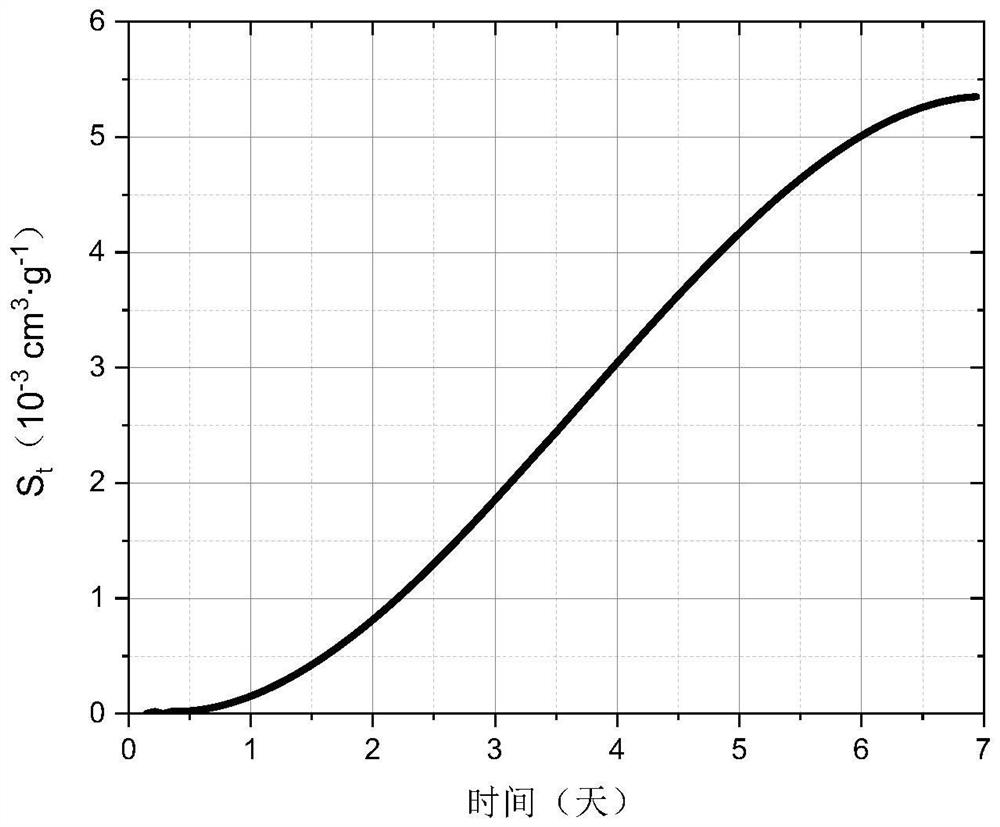

[0061] Test raw materials and proportions: Ordinary Portland cement with a strength grade of 42.5 and a water-binder ratio of 0.30.

[0062] Density ρ of saturated calcium chloride solution 液 =1.40g·ml -1 , the mass M of the elastic thin rubber bag 1 =1.6856g,

[0063] The mass M of the elastic thin rubber bag 5 loaded into the slurry 2 =2238.0986g, after being sealed and suspended on the hydrostatic balance 1, the indication of the balance is cleared, so the indication of the balance at this time is m 0 =0.000g, the ambient temperature during the test was between (24.2-25.3)°C. The data acquisition interval is 120 seconds, and the data acquisition system 7 continues to record for 7 days and then closes and derives the data. The data processing software is used to uniformly convert the indications of the hydrostatic balance into self-shrinkage values according to the formula (1), and the final result after conversion is as follows: figure 2 shown.

Embodiment 2

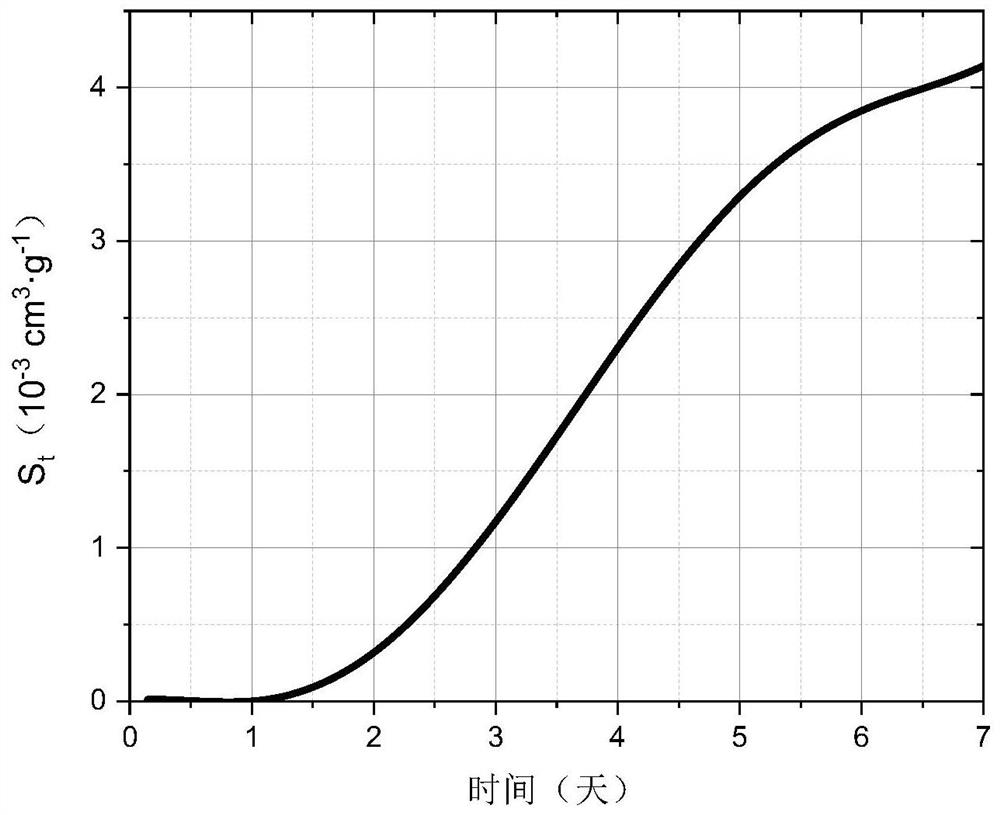

[0065] Test raw materials and ratio: the mass ratio of ordinary Portland cement with a strength grade of 42.5 to S95 grade slag powder is 7:3, and the water-cement ratio is 0.30.

[0066] Density ρ of saturated calcium chloride solution 液 =1.40g·ml -1 , the mass M of the elastic thin rubber bag 1 =1.7262g,

[0067] The mass M of the elastic thin rubber bag 5 loaded into the slurry 2 =2121.0891g, after being sealed and hung on the hydrostatic balance 1, the indication of the balance is cleared, so the indication of the balance at this time is m 0 =0.000g, the ambient temperature during the test was between (24.5-25.8)°C. The data acquisition interval is 120 seconds, and the data acquisition system 7 continues to record for 7 days and then closes and derives the data. The data processing software is used to uniformly convert the indications of the hydrostatic balance into self-shrinkage values according to the formula (1), and the final result after conversion is as follow...

Embodiment 3

[0069] Test raw materials and proportioning: the mass ratio of ordinary Portland cement with a strength grade of 42.5 to S95 slag powder is 7:3, and then 0.2% (based on the mass of cement and slag powder) of concrete internal curing agent superabsorbent resin is added , The water-binder ratio is 0.33.

[0070] Density ρ of saturated calcium chloride solution 液 =1.40g·ml -1 , the mass M of the elastic thin rubber bag 1 =1.6961g,

[0071] The mass M of the elastic thin rubber bag 5 loaded into the slurry 2 =2189.9827g, after being sealed and hung on the hydrostatic balance 1, the indication of the balance is cleared, so the indication of the balance at this time is m 0 =0.000g, the ambient temperature during the test was between (24.2-25.1)°C. The data acquisition interval is 120 seconds, and the data acquisition system 7 continues to record for 7 days and then closes and derives the data. The data processing software is used to uniformly convert the indications of the hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com