Clostridium acetobutylicum strain and application thereof

A technology of Fusobacterium acetobutylicum and strains, applied in the directions of bacteria, microorganisms, biochemical equipment and methods, etc., can solve the problems of low butanol yield, low substrate conversion rate, etc., and achieves strong butanol tolerance and proportion High, high sugar conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment illustrates that the present invention Clostridium acetobutylicum Screening method for BD518.

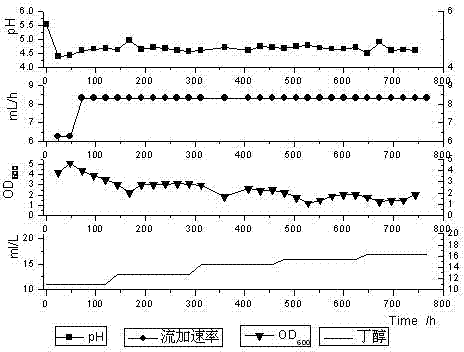

[0034] Clostridium acetobutylicum Clostridium acetobutylicum The XY16 original strain was activated and cultured at a culture temperature of 37°C, with a volume of 15-20 mL in a 50 mL Schott anaerobic bottle, filled with nitrogen for 2 minutes, and cultured for 12-18 hours to obtain a vigorously growing and robust bacterial liquid; Into a self-made continuous culture device with a liquid volume of 100-300 mL, the inoculum volume was 5%-15% (v / v), and after 12-18 hours of cultivation, a fresh medium containing butanol was added for domestication and selection. as attached figure 1 As shown, with the increasing butanol concentration, the OD of the strain decreased gradually, and the total acclimatization time was 744 h. Samples were taken at 472 h, 600 h, and 700 h of acclimatization time, spread on plates, and screened for mutants with high butanol toler...

Embodiment 2

[0051] This example illustrates Clostridium acetobutylicum Clostridium acetobutylicum BD 518 butanol resistance properties.

[0052] The medium formula described in this embodiment (% is mass percent):

[0053] Primary seed medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipotassium hydrogen phosphate 0.1 %, ferrous sulfate heptahydrate 0.01%, the rest is water, pH 6.

[0054] Secondary seed medium: yeast powder 0.3%, peptone 0.5%, soluble starch 1%, ammonium acetate 0.2%, sodium chloride 0.2%, magnesium sulfate heptahydrate 0.3%, potassium dihydrogen phosphate 0.1%, dipotassium hydrogen phosphate 0.1 %, ferrous sulfate heptahydrate 0.01%, the rest is water, pH 6.

[0055] Butanol tolerance test medium: glucose 6%, ammonium acetate 0.22%, potassium dihydrogen phosphate 0.05%, dipotassium hydrogen phosphate 0.05%, sodium chloride 0.001%, magnes...

Embodiment 3

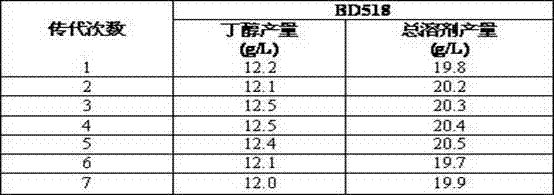

[0058] This example illustrates the passage stability of the mutant strain BD518.

[0059] In the fermentation medium with glucose as the carbon source, the passage stability of the mutant strain BD518 was detected, and the results of the passage fermentation test of the strain BD518 are shown in Table 2:

[0060] Table 2 strain BD518 passage fermentation test result

[0061]

[0062] From the experimental results, it can be seen that after 7 consecutive passages, the total solvent production and butanol production of the two mutant strains are relatively stable, and they have good passage stability, and can be used as production strains for further research and development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com