Biochip incubation reactor

A bio-chip and reactor technology, which is applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc. Simple and novel structure, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

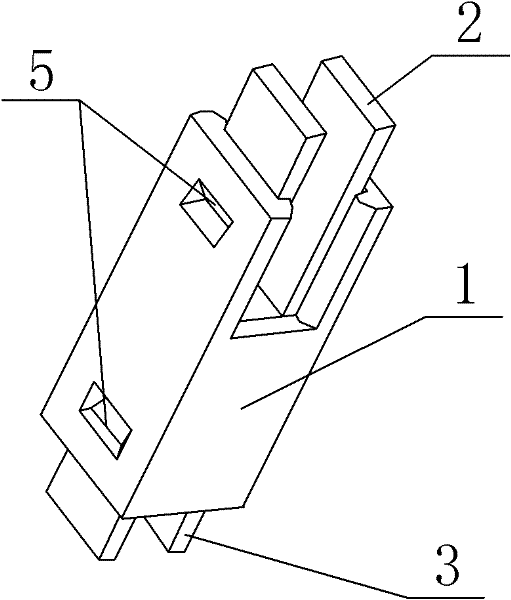

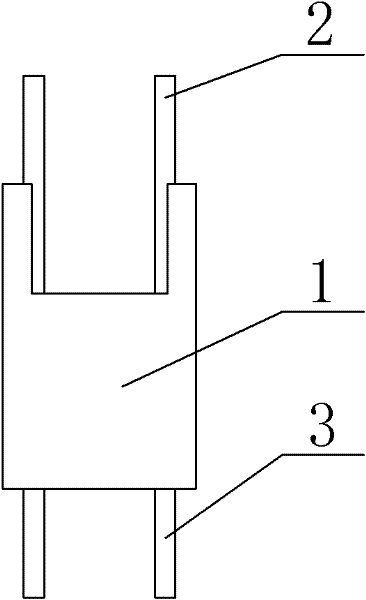

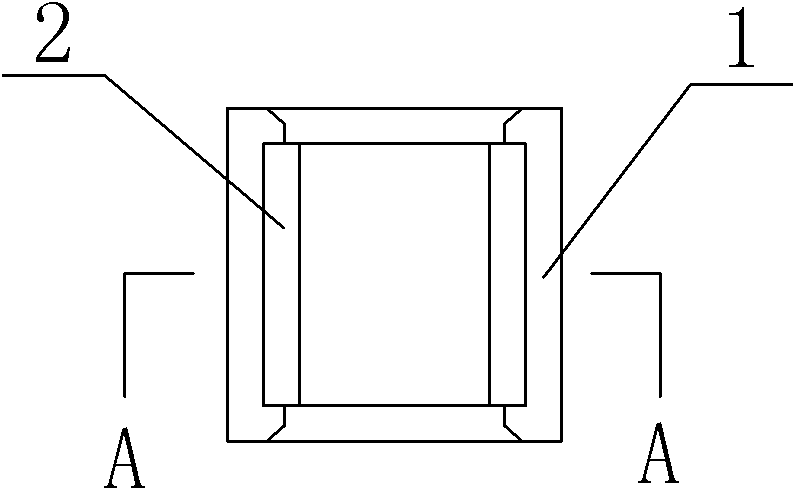

[0044] Such as figure 1 , figure 2 , image 3 with Figure 4The shown biochip incubation reactor comprises a reaction chamber 1, an upper cover plate 2 and a lower cover plate 3 symmetrically installed in the reaction chamber 1; a boss 4 is arranged on the inner wall of the reaction chamber 1, and the The boss 4 is integrally formed with the reaction chamber 1 and the boss 4 has a hollow structure as the incubation reaction chamber 6, and a gap for installing a biochip is provided between the lower cover surface of the upper cover plate 2 and the boss 4, so There is also a gap for installing biochips between the upper cover surface of the lower cover plate 3 and the boss 4; Contact; the gap between the lower cover surface of the upper cover plate 2 and the boss 4 is 0.2mm to 10mm, and the gap is preferably 0.2mm, 1.0mm, 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm mm, 7.0mm, 8.0mm, 9.0mm, 10mm; the gap between the upper cover surface of the lower cover plate 3 and the boss 4 is 0.2m...

Embodiment 2

[0046] Such as Figure 5 , Image 6 , Figure 7 with Figure 8 The shown biochip incubation reactor comprises a reaction chamber 1, an upper cover plate 2 and a lower cover plate 3 symmetrically installed in the reaction chamber 1; a boss 4 is arranged on the inner wall of the reaction chamber 1, and the The boss 4 is integrally formed with the reaction chamber 1 and the boss 4 has a hollow structure as the incubation reaction chamber 6, and a gap for installing a biochip is provided between the lower cover surface of the upper cover plate 2 and the boss 4, so There is also a gap for installing biochips between the upper cover surface of the lower cover plate 3 and the boss 4; Contact; the gap between the lower cover surface of the upper cover plate 2 and the boss 4 is 0.2mm to 10mm, and the gap is preferably 0.2mm, 1.0mm, 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm mm, 7.0mm, 8.0mm, 9.0mm, 10mm; the gap between the upper cover surface of the lower cover plate 3 and the boss 4 is 0....

Embodiment 3

[0048] Such as Figure 9 , Figure 10 , Figure 11 with Figure 12 The shown biochip incubation reactor comprises a reaction chamber 1, an upper cover plate 2 and a lower cover plate 3 symmetrically installed in the reaction chamber 1; a boss 4 is arranged on the inner wall of the reaction chamber 1, and the The boss 4 is integrally formed with the reaction chamber 1 and the boss 4 has a hollow structure as the incubation reaction chamber 6, and a gap for installing a biochip is provided between the lower cover surface of the upper cover plate 2 and the boss 4, so There is also a gap for installing biochips between the upper cover surface of the lower cover plate 3 and the boss 4; Contact; the gap between the lower cover surface of the upper cover plate 2 and the boss 4 is 0.2mm to 10mm, and the gap is preferably 0.2mm, 1.0mm, 2.0mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm mm, 7.0mm, 8.0mm, 9.0mm, 10mm; the gap between the upper cover surface of the lower cover plate 3 and the boss 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com