Liquid crystal composition

A liquid crystal composition and composition technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of display screen lag, slow response speed, etc., and achieve short response time, high voltage retention rate, and wide nematic phase temperature range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

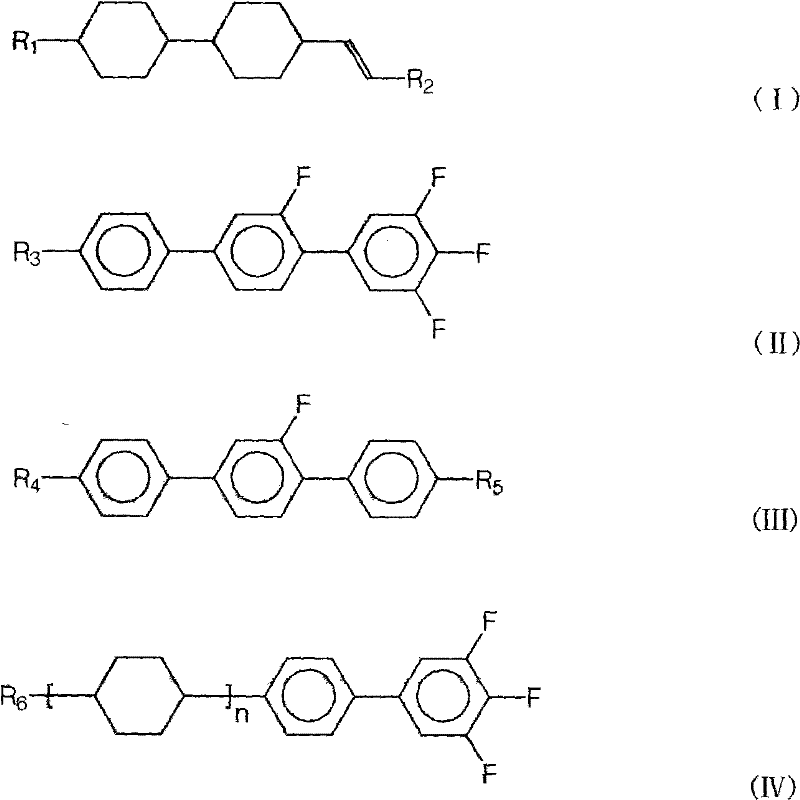

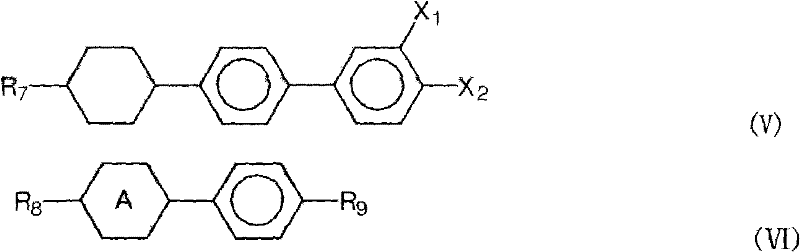

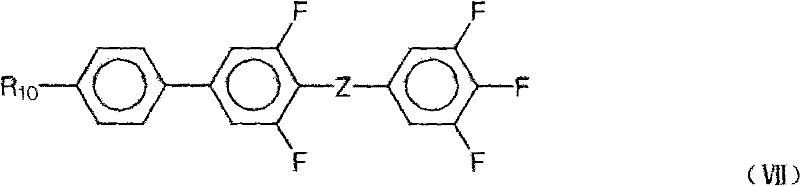

Method used

Image

Examples

preparation example Construction

[0061] The preparation of the composition of the present invention is to select its weight percentage according to the ratio range of these several compounds, and carry out according to a conventional method. The usual conventional preparation method is to mix and heat its components to dissolve each other until the completion of the dissolution process is observed. But it is also possible to dissolve and mix the components in a suitable organic solvent (a suitable organic solvent such as acetone, chloroform or methanol), and remove the solvent after thorough mixing to finally obtain a uniform liquid crystal composition. This method must ensure that no pollutants or unnecessary dopants are introduced into the solvent.

[0062] The liquid-crystalline media according to the invention can also further comprise additives known to the skilled person and described in the literature, making it possible to use them in any type of liquid-crystal display disclosed so far.

Embodiment 1

[0077]

[0078]

[0079] The physical parameters of the composition are as follows:

[0080] T NI =76℃ ΔN=0.126 Δε=+4.76 V 90 =2.03V

Embodiment 2

[0082]

[0083]

[0084] The physical parameters of the composition are as follows:

[0085] T NI =78℃ ΔN=0.124 Δε=+4.43 V 90 =1.97V

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical anisotropy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com