Method for removing impurities from potassium lactate solution

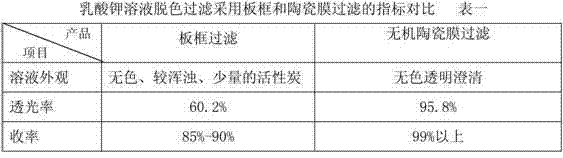

A potassium lactate, solution technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of poor clarity and opacity of the filtrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Potassium lactate is prepared as an aqueous solution with a concentration of 25% by mass and a pH value of 6.0. At a temperature of 20°C, the potassium lactate solution flows through a desodination column equipped with an inorganic ceramic membrane, and the flow rate of the potassium lactate solution is controlled to 400L / h , to complete the removal of impurities in the potassium lactate solution. The membrane layer thickness of the inorganic ceramic membrane is 50 μm, and the membrane pore diameter is 0.01 μm.

Embodiment 2

[0022] Potassium lactate is prepared as an aqueous solution with a concentration of 25% by mass and a pH value of 7.0. At a temperature of 45°C, the potassium lactate solution flows through a desodination column equipped with an inorganic ceramic membrane, and the flow rate of the potassium lactate solution is controlled at 500L / h , to complete the removal of impurities in the potassium lactate solution. The membrane layer thickness of the inorganic ceramic membrane is 55 μm, and the membrane pore diameter is 0.15 μm.

Embodiment 3

[0024] Potassium lactate was prepared as an aqueous solution with a concentration of 25% by mass and a pH value of 8.0. At a temperature of 55°C, the potassium lactate solution was passed through a desodination column equipped with an inorganic ceramic membrane, and the flow rate of the potassium lactate solution was controlled to be 700L / h , to complete the removal of impurities in the potassium lactate solution. The membrane layer thickness of the inorganic ceramic membrane is 55 μm, and the membrane pore diameter is 0.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com