Slip casting preparation method for gradient materials in movement magnetic field

A technology of moving magnetic field and gradient material, which is applied in the direction of magnetism of inorganic materials, to achieve the effect of process simplification and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

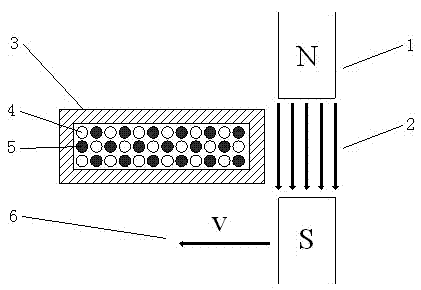

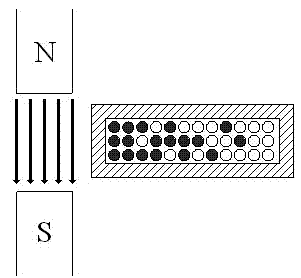

[0027] The steps of the grouting method for preparing gradient materials in a moving magnetic field are as follows:

[0028] 1) Plaster mold preparation

[0029] α-gypsum and β-gypsum are mixed with water at 15-25°C, stirred for 3-8 minutes and then poured. 30% of the environment is preserved. Gypsum is processed by calcining natural gypsum rock, the higher the purity of gypsum rock, the better the quality of gypsum. According to different processing processes, gypsum can be divided into α-gypsum and β-gypsum. α-gypsum has high strength and poor water absorption, while β-gypsum has good water absorption and poor strength. The fineness of the plaster also has an effect on strength and water absorption, as the fineness increases, the resulting mold will be stronger but less water absorbent. We not only require the plaster mold used to have strong water absorption, but also require it to have a certain strength, so it is formulated with mixed gypsum. The temperature of the w...

Embodiment 1

[0040] 1) After the gypsum mold made by solidifying and hardening the gypsum slurry is dried, the internal cavity of the mold is a cuboid of 30mm×10mm×5mm;

[0041] 2) Nickel powder with an average particle size of 3 μm and Al with an average particle size of 0.9 μm 2 o 3 The powder is mixed with water in a ratio of 1:10, mixed with water, and added with 0.2% caustic soda, stirred in a ball mill for 5 hours, added with a content of 0.5% polyvinyl butyral binder, and ball milled for 5 hours to produce Uniformly dispersed slurry, which is dispersed by ultrasonic waves. The humidity of the obtained pouring slurry is 45%, the temperature is 30°C, the viscosity is 80mPa·s, and the pH value of the slurry is 8.5;

[0042] 3) When grouting, the mold temperature is 25°C, and the mold is wiped with 3% soda solution. The slurry is filled into the plaster mold, and a moving magnetic field is applied outside the mold. The moving magnetic field is generated by a magnetic circuit compose...

Embodiment 2

[0046] 1) After the gypsum mold made by solidifying and hardening the gypsum slurry is dried, the internal cavity of the mold is a cuboid of 30mm×10mm×5mm;

[0047] 2) Select aluminum powder with an average particle size of 50 μm and Al powder with an average particle size of 2.2 μm 2 o 3 The powder is mixed in a ratio of 1:1 to form a mixed powder, which is mixed with ethanol, and a polyvinyl butyral dispersant with a content of 2% is added, stirred in a ball mill for 8 hours, and a trimethylpropane triacrylate binder is added, and continued Ball mill for 8 hours to make a uniformly dispersed slurry. The pH value of the suspension was adjusted to 5, and ultrasonic wave was used for dispersion treatment. The humidity of the obtained pouring slurry is 35%, the temperature is 35°C, and the viscosity is 38mPa·s;

[0048] 3) When grouting, the mold temperature is 25°C, and the working surface of the mold is wiped with 3% soda solution. The slurry is filled into the plaster mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com