Method for measuring thickness by pulse infrared thermal wave technology

A technology of infrared thermal wave and pulse heating, which is applied in the field of infrared thermal wave technology, can solve the problems of error, second-order differential peak time noise, and difficult to implement, etc., and achieve the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

[0023] The theoretical basis of the present invention is based on the solution of the one-dimensional heat conduction equation under the excitation of a pulse plane heat source. For a semi-infinite homogeneous medium, when subjected to a uniform pulse heat source parallel to the surface of the medium, the heat conduction equation can be simplified as:

[0024]

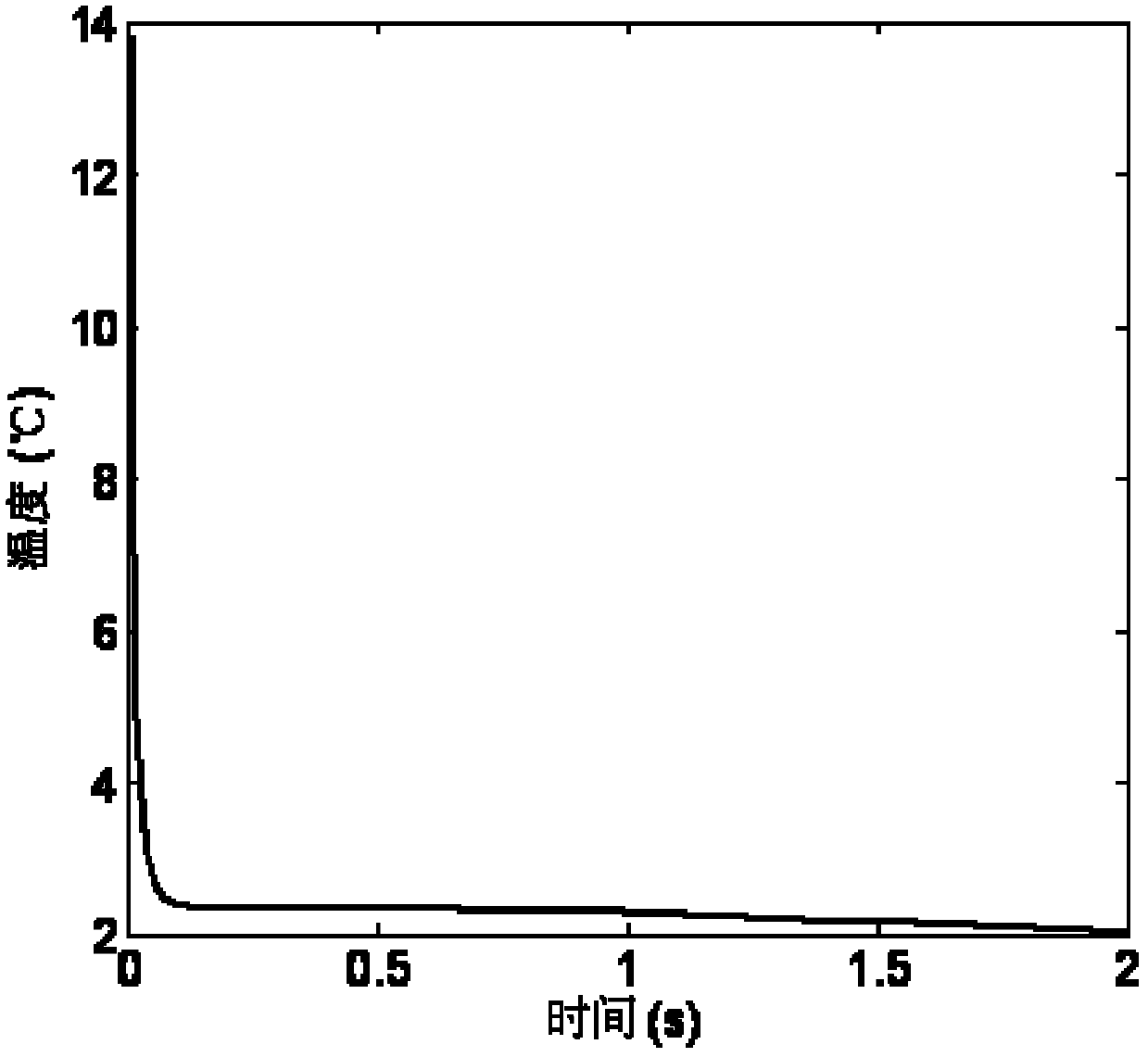

[0025] Among them, T(x, t) is the temperature at time t at x, qδ(t)δ(x) is the pulse heat source function, q is a constant, which is the heat applied on the unit area, k(W / m K) is the thermal conductivity. Density ρ(kg / m 3 ) and the product of the specific heat c is the bulk heat capacity of the dielectric material. The thermal diffusivity is α=k / (pc). For a certain medium, α can be regarded as a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com