Water beam with thermal insulating sleeve for heating furnace

A thermal insulation and heating furnace technology, which is applied in the field of thermal insulation accessories, can solve problems such as unsatisfactory effects, achieve the effects of reducing the number of shutdowns for maintenance and maintenance costs, long service life, and reducing maintenance costs and shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

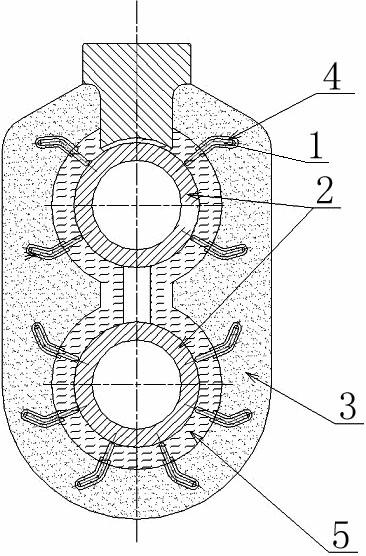

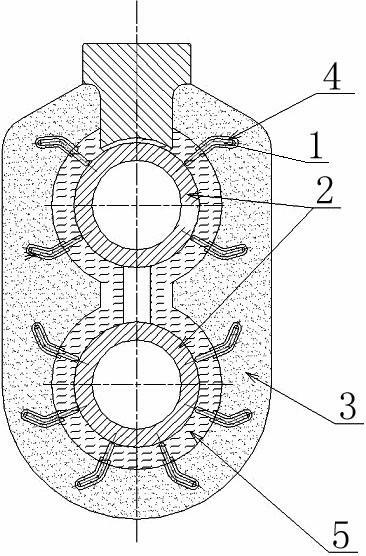

[0012] A water beam with thermal insulation sleeve for heating furnace, including anchor nail 1, water beam 2, pouring material 3, insulation sleeve 4 and fiber blanket 5, such as figure 1 As shown, the specific structure is: one end of the anchor nail 1 is welded and fixed on the outer surface of the water beam 2, the anchor nail 1 is used to fix the refractory material, the insulating sleeve 4 is woven by glass fiber, and the insulating sleeve 4 is set on the anchor nail 1. On the outer surface, the fiber blanket 5 is wrapped on the outer surface of the water beam 2, and the pouring material 3 is poured on the outer surface of the water beam 2 and wrapped with the insulating sleeve 4 and the anchor nail 1. The cross section of the anchor nail 1 is two line segments with a common end point, and the angle formed by the two line segments is 90°-150°, which is 120° in this embodiment.

[0013] In this embodiment, the insulating sleeve 4 is placed on the outer surface of the anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com