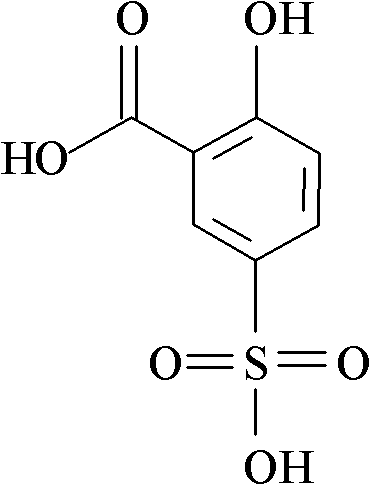

Method for purifying 5-sulfosalicylic acid

A sulfosalicylic acid and purification method technology, applied in the field of 5-sulfosalicylic acid purification, can solve the problems of cumbersome operation, high cost, high energy consumption, etc., and achieve safe and convenient purification process and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 100g of industrial grade 5-sulfosalicylic acid in 1000mL of deionized water, add 20g of activated carbon under stirring, keep the temperature at 42±2°C for 5 hours, filter to remove the activated carbon, and pass the obtained filtrate through the device at a flow rate of 10ml / min. There is a 1000g 4A molecular sieve separation column with a heating device, and the column temperature is kept at 75±5°C. The collected liquid is concentrated at 100°C and recrystallized to obtain 82.5g of the purified white crystalline product 5-sulfosalicylic acid. 99.1% purity.

Embodiment 2

[0022] Dissolve 100g of industrial grade 5-sulfosalicylic acid in 500mL of deionized water, add 10g of activated carbon under stirring, maintain the temperature at 50±2°C for 6 hours, filter to remove the activated carbon, and pass the obtained filtrate through the device at a flow rate of 15ml / min. There is a 1500g 4A molecular sieve separation column with a heating device, and the column temperature is kept at 85°C. The collected liquid is concentrated at 100°C and recrystallized to obtain 83.7g of purified white crystalline product 5-sulfosalicylic acid with a purity of 99.2 %.

Embodiment 3

[0024] Dissolve 100g of industrial grade 5-sulfosalicylic acid in 400mL of deionized water, add 10g of activated carbon under stirring, maintain the temperature at 58±2°C for 8 hours, filter to remove the activated carbon, and pass the obtained filtrate through the device at a flow rate of 20ml / min. There is a 1500g 4A molecular sieve separation column with a heating device, and the column temperature is kept at 95°C. The collected liquid is concentrated at 100°C and recrystallized to obtain 86.2g of purified white crystalline product 5-sulfosalicylic acid with a purity of 99.2 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com