Method for controlling physical dimension of magnesium oxide sintered target by using temperature gradient

A technology of physical size and temperature gradient, which is applied in the field of magnesium oxide sintered target material preparation, can solve the problems affecting the expansion contact of magnesium oxide particles, uneven driving force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

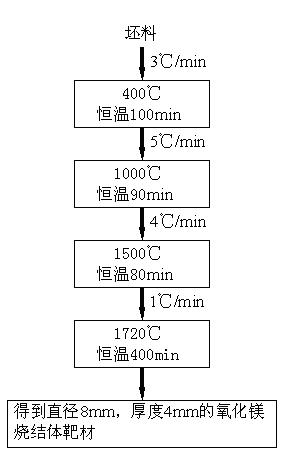

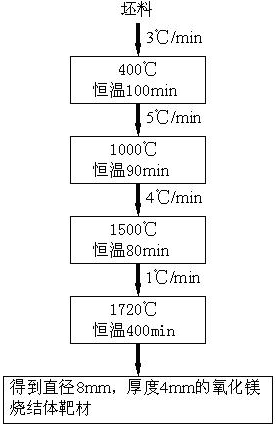

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] refer to figure 1 , use magnesium oxide powder with a diameter of 0.5 to 1 μm, press it into a diameter of 12mm, a thickness of 6mm, use propanol as a binder, zinc stearate as a release agent, and control the moisture content at about 2.5%.

[0021] (1) Raise to 400°C at a rate of 3°C / min, and keep the temperature constant for 100 minutes;

[0022] (2)

[0023] (3) Raise the temperature to 1500°C at a rate of 4°C / min, and keep the temperature constant for 80 minutes;

[0024] (4) Raise the temperature to 1720°C at a rate of 1°C / min, and keep the temperature constant for 400 minutes.

[0025] After the above 4 heating sections and 4 constant temperature sections, a sintered magnesium oxide target with a diameter of 8mm and a thickness of 6mm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com