Removing agent for removing carbonyl iron and carbonyl nickel in syngas and preparation method thereof

A technology for synthesis gas and removing agent, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve problems such as catalyst life that affects product yield, catalyst poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

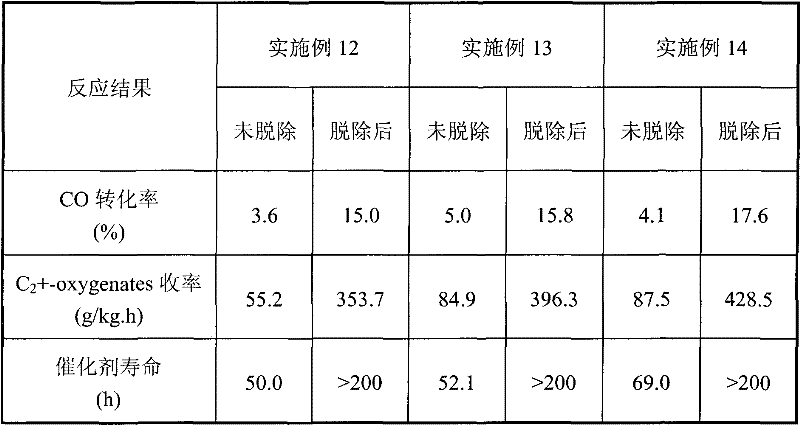

Examples

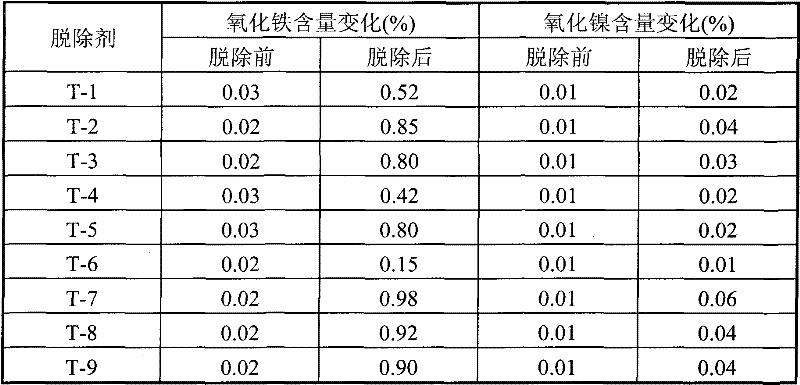

Embodiment 1

[0020] Weigh 1.65g of potassium nitrate and 3.1g of copper nitrate (containing 6 crystal waters), add 4.5g of deionized water, dissolve and mix the copper nitrate and potassium nitrate evenly, then add 5.0g of γ-Al 2 o 3 , after soaking for 5 hours, put it into an oven and dry at 100°C for 18 hours, and finally bake at 600°C for 2 hours. Get Cu(10.5%)-K(10.1%) / γ-Al 2 o 3 (79.4%) remover, numbered T-1.

Embodiment 2

[0022] Weigh 19.1g magnesium nitrate (containing 6 crystal waters), 7.4g copper nitrate (containing 6 crystal waters) and dissolve in 3.0g deionized water, mix well and add 5.0g γAl 2 o 3 , after soaking for 2 hours, put it in an oven and dry it at 80°C for 36 hours, and finally bake it at 500°C4. Get CuO(20%)-MgO(30%) / γ-Al 2 o 3 (50%) remover, numbered T-2.

Embodiment 3

[0024] Weigh 9.9g magnesium nitrate (containing 6 crystal waters), 1.45g copper nitrate (containing 6 crystal waters) and dissolve in 2.3g deionized water, mix well and add 5.0g γAl 2 o 3 , after soaking for 7 hours, put it in an oven to dry at 150°C for 1 hour, and finally bake at 300°C for 6 hours. Obtain Cu(5%)-Mg(15%) / γ-Al 2 o 3 (80%) remover, numbered T-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com