Method for mixing oxalate and hydrogen

A technology of oxalate and hydrogen, which is applied in mixing methods, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of poor mixing effect of oxalate and hydrogen, and high decomposition rate of oxalate, and achieve engineering scale-up. Problems, shorter dwell time, effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

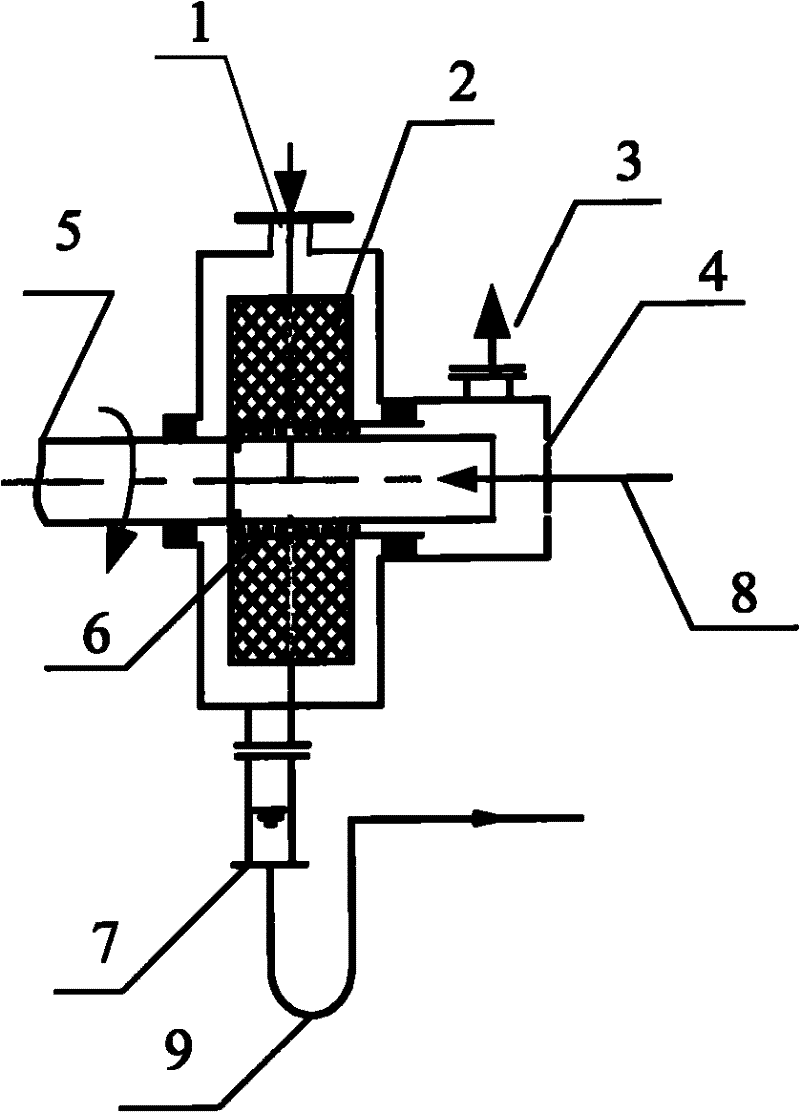

[0027] The mixing of dimethyl oxalate and hydrogen is carried out in the rotating packed bed supergravity field device, and it is used in the reaction of hydrogenation of dimethyl oxalate to ethylene glycol. Attached figure 1 The rotating packed bed supergravity field device shown.

[0028]Hydrogen enters the rotating packed bed hypergravity field mixing device through the gas inlet 1, and diffuses into the rotating packing 2 under the action of pressure difference, and the rotating packing speed is adjusted to 2000rpm. The dimethyl oxalate solution is introduced into the inside of the liquid distributor 6 and the rotary packing 2 through the liquid inlet pipeline 8 through the liquid inlet 4, the molar ratio of hydrogen to dimethyl oxalate is 100:1, the mixing temperature is 190°C, and the pressure is 3.0MPa, the residence time is 0.1 second, the gas and the liquid are in countercurrent contact in the filler, the mixed effluent is gas, which is discharged through the gas out...

Embodiment 2

[0030] The mixing of diethyl oxalate and hydrogen is carried out in the rotating packed bed supergravity field device, and it is used in the reaction of hydrogenation of diethyl oxalate to ethylene glycol. Attached figure 2 The rotating packed bed supergravity field device shown.

[0031] Hydrogen enters the rotating packed bed hypergravity field mixing device through the gas inlet 3, and diffuses into the rotating packing 2 under the action of pressure difference, and the rotating packing speed is adjusted to 5000rpm. The diethyl oxalate solution is introduced into the inside of the liquid distributor 6 and the rotary packing 2 through the liquid inlet pipeline 8 through the liquid inlet 4, the molar ratio of hydrogen to diethyl oxalate is 80:1, the mixing temperature is 195°C, and the pressure is 2.5MPa, the residence time is 0.08 seconds, the gas and the liquid are co-currently contacted in the filler, the mixed effluent is gas, and the gas effluent is discharged through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com