Dipping liquid crystal welding goggle

A technology of goggles and liquid crystal lenses, applied in goggles, optics, nonlinear optics, etc., can solve the problems of single light transmittance and limit the flexibility of welding personnel to achieve the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

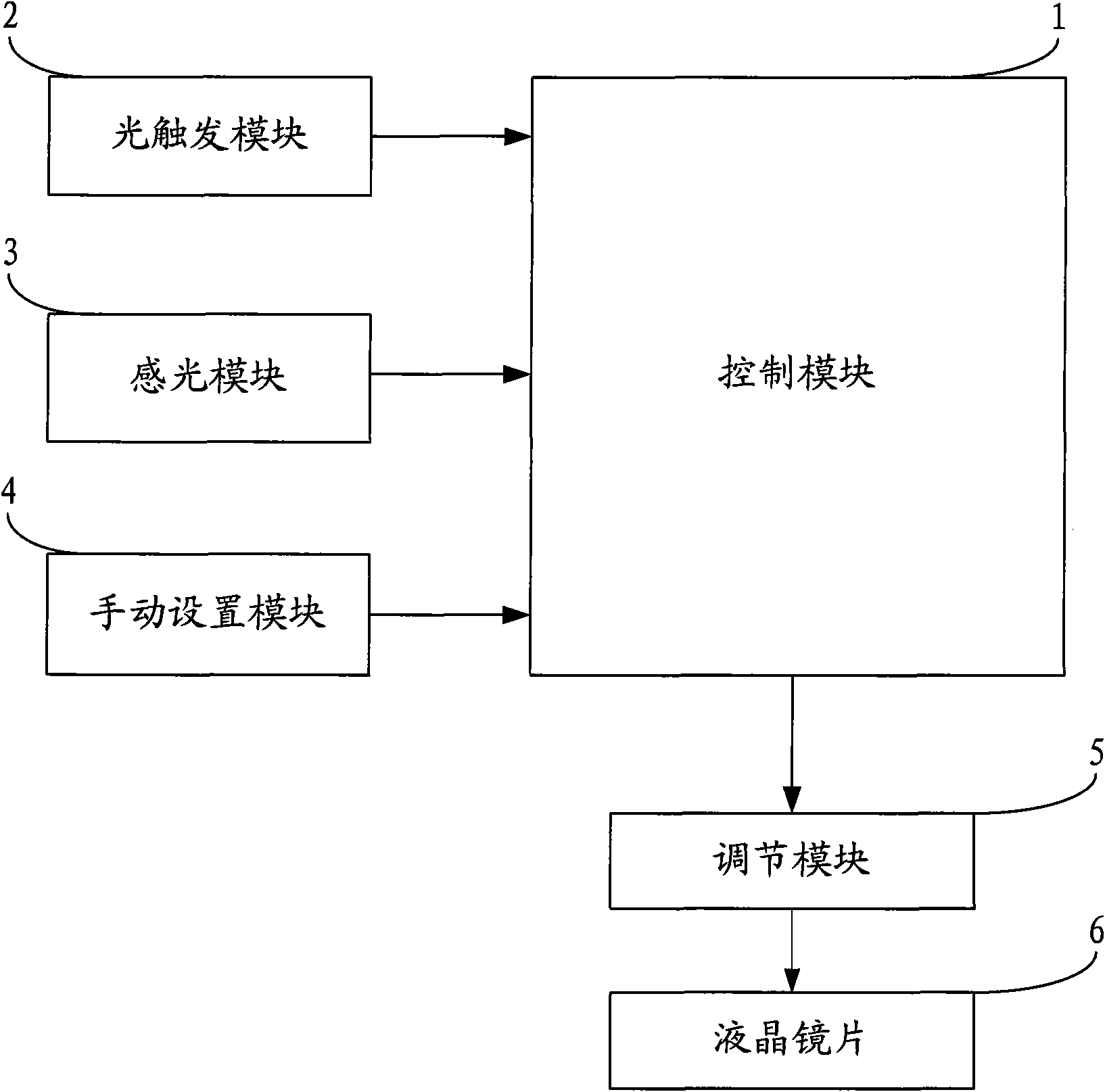

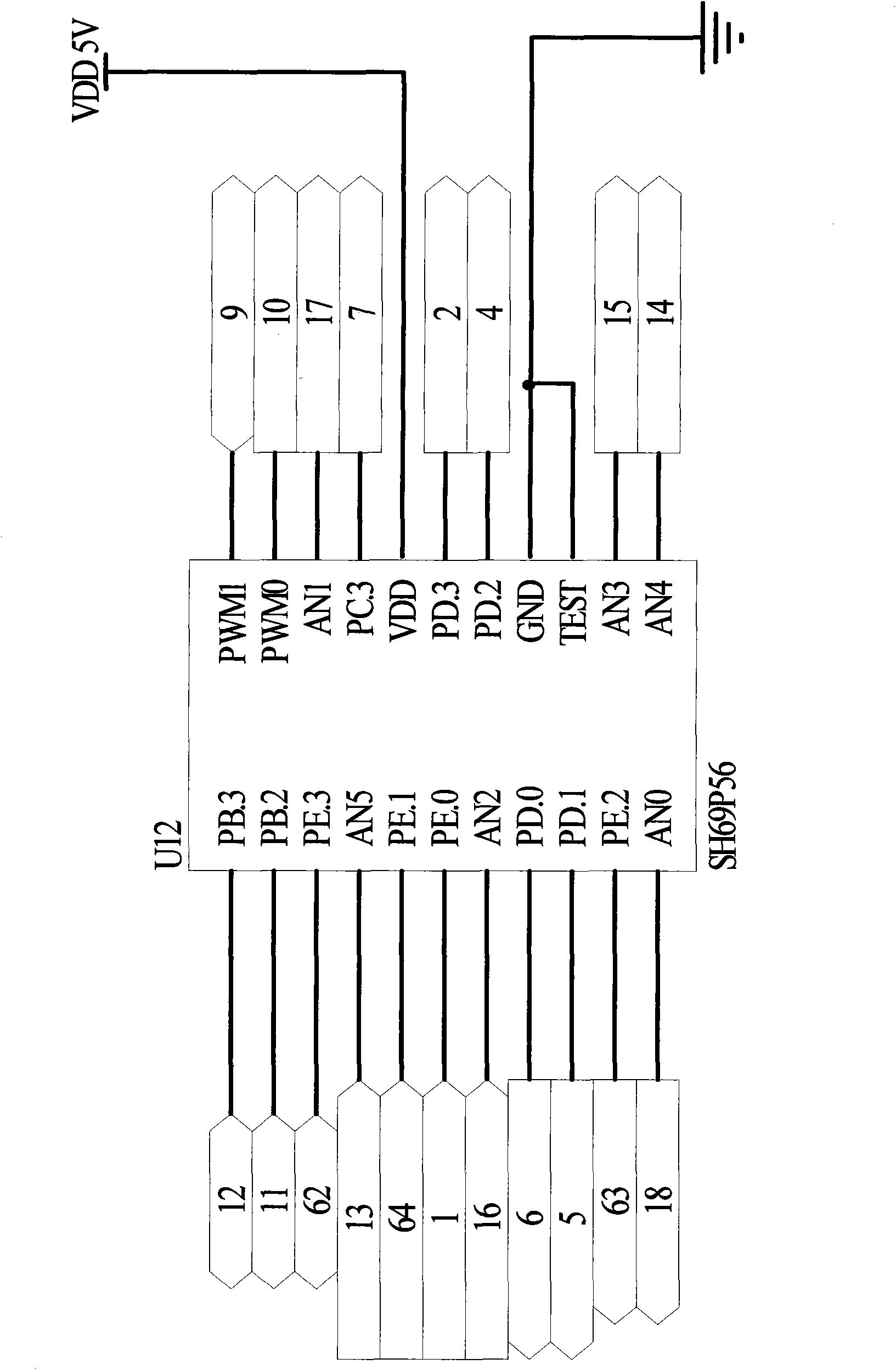

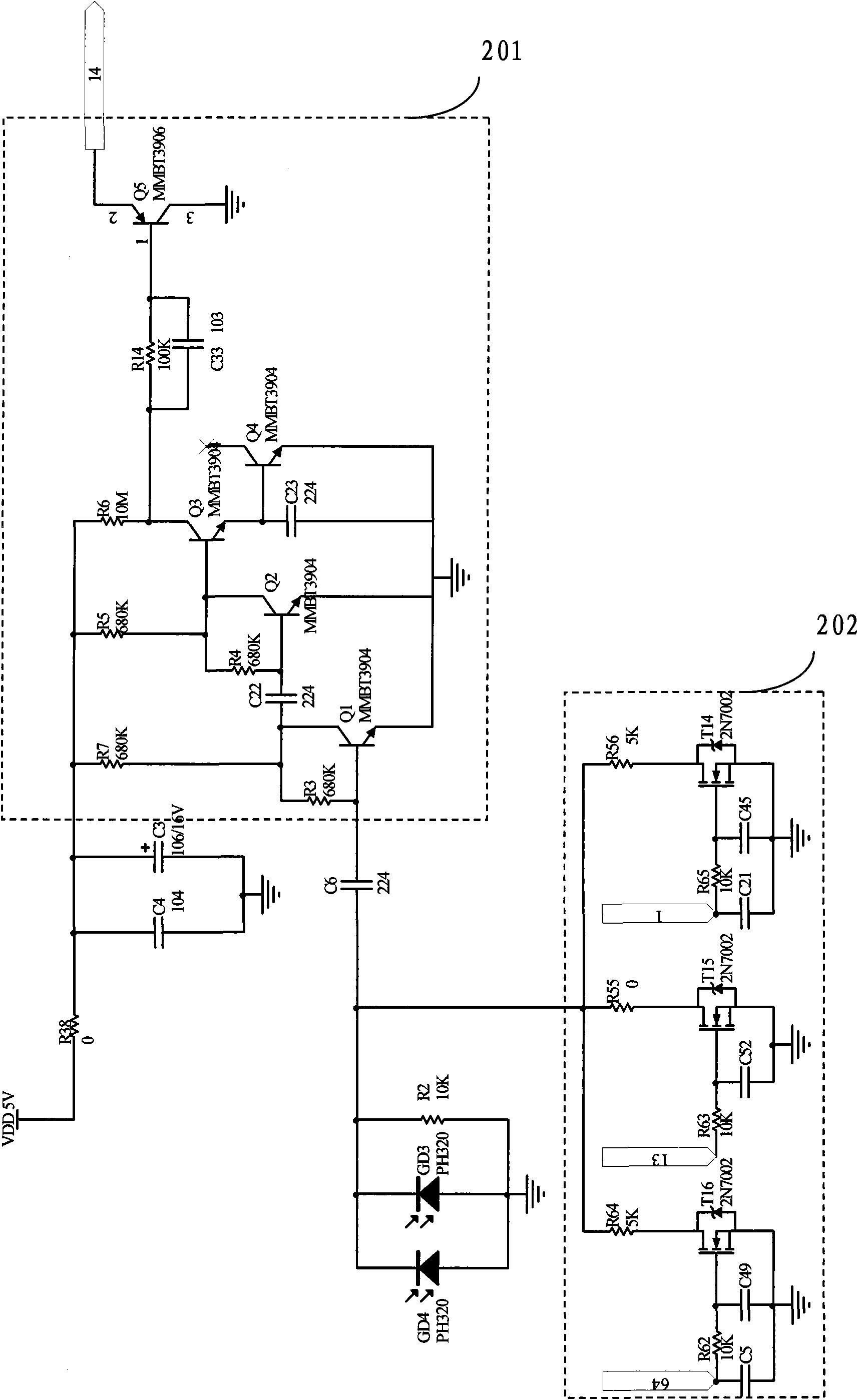

[0032] In this embodiment, the control module 1 adopts the SH69P56 DSP processor produced by Xinyang Technology Co., Ltd. of Taiwan, such as figure 2 As shown, its main function is that it can receive the light intensity signal from the photosensitive module 3 in real time and perform digital processing on the parameters set by the manual setting module 4, convert it into a PWM wave, and adjust it by sending out a PWM wave from the adjustment module 5. The adjustment module 5 can adjust the light transmittance of the liquid crystal lens 6 in time according to the strength of the welding arc, so as to protect the eyesight of the welding personnel and enhance the flexibility of the welding personnel's operation. figure 2 In the DSP processor SH69P56, the 9th pin is the power supply and charging control pin of the LCD lens, the 10th pin is the high-voltage charging pin, the 17th pin is the LCD power supply detection pin, and the 7th pin is the charging pin. Pin 2 and pin 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com