Phytocide granule and preparation method of granule

A technology of herbicides and granules, which is applied in the field of herbicide granules and its preparation, can solve the problems of low herbicide loading and poor slow-release effect, and achieve control of pesticide pollution, prolong release time, and strengthen slow-release effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 5 g of carboxymethyl chitosan to 100 g of water, stir until it is completely dissolved, then add 3 g of bentonite, 2 g of herbicide 2,4-D-butyl (2,4-dichlorophenoxybutyl acetate) , stir thoroughly to form a homogeneous suspension. Prepare 1000 mL of calcium chloride (cross-linking agent) aqueous solution with a mass concentration of 6%, add the above suspension into the cross-linking agent solution dropwise with a peristaltic pump, and react at 60°C for 5 minutes to obtain a granular product. Filter out and then dry at 70°C for 2 h to obtain herbicide granules with an average particle size of about 0.8 mm. After extraction and analysis, the mass content of 2,4-D butyl ester in the preparation was 18.2%, and the loading rate of 2,4-D butyl ester was 91.0%.

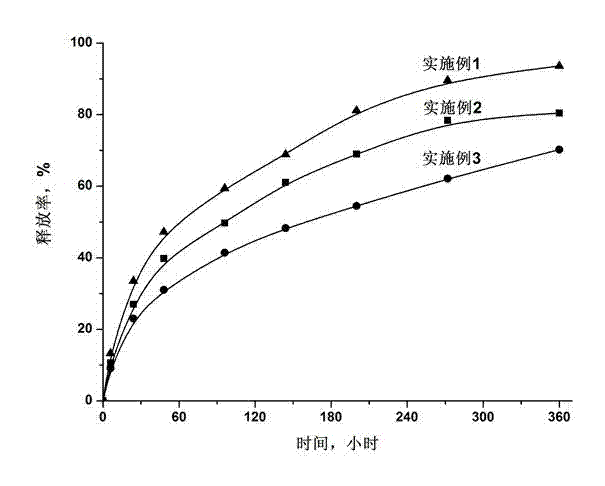

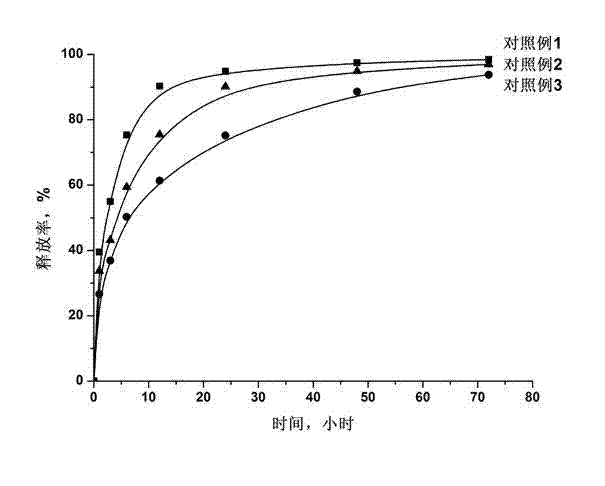

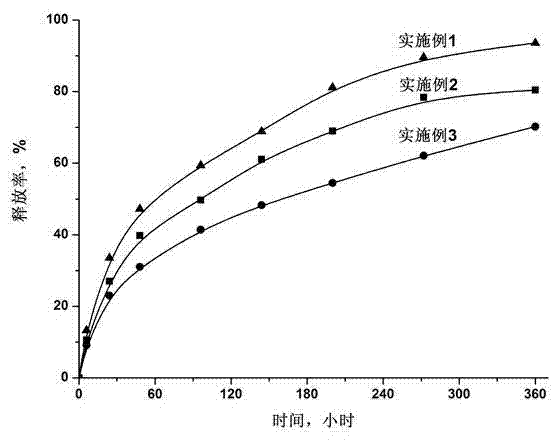

[0019] The herbicide preparation prepared above was subjected to a release test, and 100 mg of the preparation sample was put into 1000 mL of water. After a certain interval, water samples were taken to analyze ...

Embodiment 2

[0021] 4.5 g of bentonite was taken and ion-exchanged with 10 mL of 20% sulfuric acid aqueous solution, the solid was separated by centrifugation, and 4.0 g of acid-activated bentonite was obtained by drying.

[0022] Add the above-mentioned acid-activated bentonite to 100 g of carboxymethyl chitosan aqueous solution (the mass content of carboxymethyl chitosan is 3%), stir evenly, add 3 g of herbicide metolachlor, fully stir and mix until uniform suspension. Then use a peristaltic pump to drop into the cross-linking agent solution as described in Example 1, react at 60°C for 3 minutes to obtain a granular product, then dry at 70°C for 2 h to obtain an average particle diameter of about 0.9 mm The herbicide preparation, wherein the mass content of metolachlor is 26.5% after extraction and analysis, and the entrapment rate of metolachlor is 88.3%. Get this preparation sample 70 mg, adopt the method described in embodiment 1 to carry out release experiment, obtain the release ra...

Embodiment 3

[0024] Take 3 g of bentonite, conduct ion exchange reaction with 30 mL of cetyldimethylammonium chloride aqueous solution with a mass concentration of 2%, centrifuge to separate the solid, and dry to obtain 3.1 g of organically modified bentonite.

[0025] Prepare 100 g of carboxymethyl chitosan aqueous solution with a mass content of 4%, add the above-mentioned organically modified bentonite and 4 g of the herbicide alachlor in sequence, and stir thoroughly to form a uniform suspension. Prepare 500 mL of calcium chloride aqueous solution and glutaraldehyde aqueous solution with a mass concentration of 10%, respectively, and use them as cross-linking agents after mixing evenly. Add the above suspension into the crosslinking agent solution dropwise with a peristaltic pump, react at 50°C for 3 minutes to obtain a granular product, filter the particles, and then dry at 70°C for 2 hours to obtain an average particle size of about 1.0 mm herbicide granules. After extraction and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com