Semiconductor structure with through holes and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., to achieve the effects of improving performance, increasing flexibility, and improving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

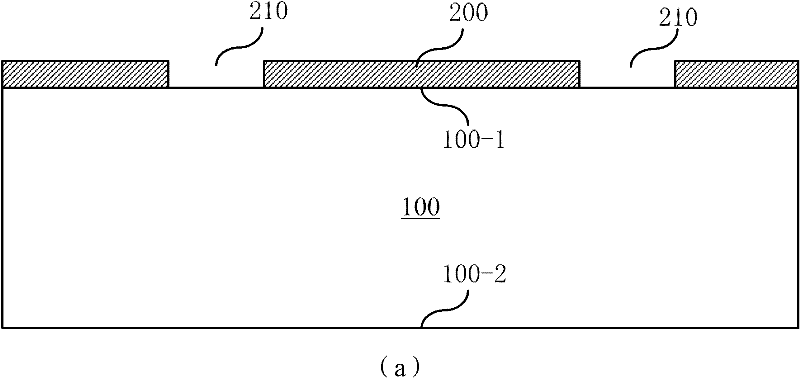

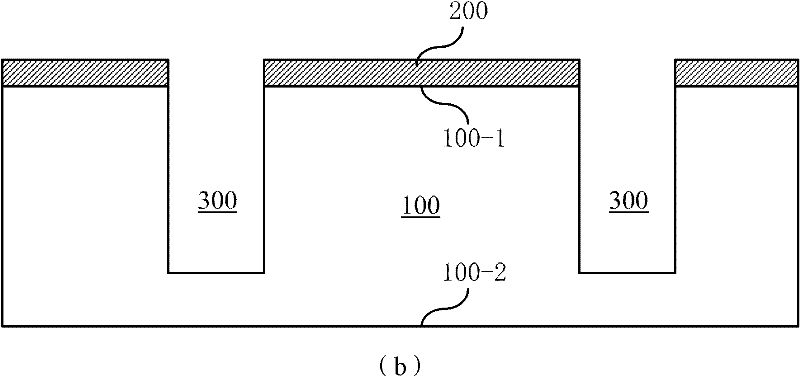

[0048]Firstly, the semiconductor structure with through holes provided by the present invention is summarized below. The semiconductor structure includes a substrate 100, a plurality of annular through holes 302, and a plurality of solid through holes 301, wherein:

[0049] The substrate 100 has opposite first surface 100-1 and second surface 100-2;

[0050] The annular through hole 302 and the solid through hole 301 are embedded in the substrate and penetrate through the substrate 100 in a direction perpendicular to the first surface 100-1 and the second surface 100-2;

[0051] The solid through hole 301 is filled with a solid metal plug 340;

[0052] The annular through hole 302 is filled by a solid dielectric plug 350 and a metal ring 330 surrounding the solid dielectric plug.

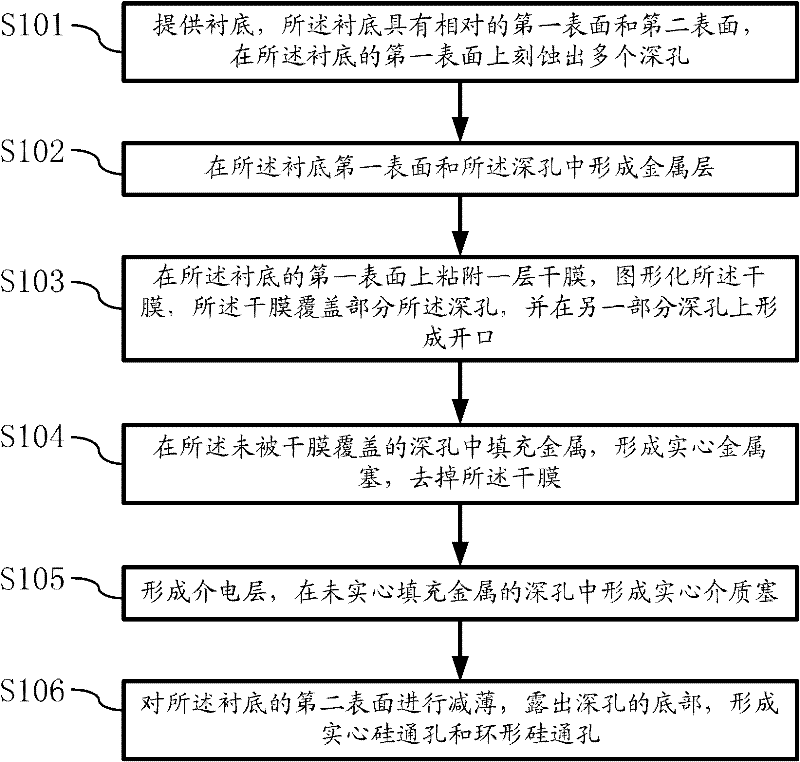

[0053] The semiconductor manufacturing method such as figure 1 shown, including the following steps:

[0054] In step S101, a substrate 100 is provided, the substrate 100 has opposite first surfa...

Embodiment 2

[0064] Optionally, the semiconductor structure with through holes in this embodiment can be based on the semiconductor structure in Embodiment 1, between the metal plug 340 of the solid through hole 301 and the substrate 100, and the metal ring of the annular through hole 302 Between 330 and the substrate 100 , an insulating layer 310 connected to the substrate and a barrier layer 320 surrounding the metal plug 340 and the metal ring 330 are added.

[0065] On the basis of the manufacturing method of embodiment 1, increase following steps:

[0066] After etching the deep hole 300 in step S101, an insulating layer 310 is formed on the first surface 100-1 of the substrate 100 and the deep hole 300;

[0067] After the above-mentioned insulating layer 310 is formed, a barrier layer 320 is formed on the insulating layer 310 . The barrier layer 320 is present in both the first surface 100 - 1 of the substrate 100 and the deep hole 300 .

[0068] After the above two steps are compl...

Embodiment 3

[0075] Optionally, the semiconductor structure with through-silicon vias in this embodiment can be based on Embodiment 1 or 2, on the first surface 100-1 of the substrate 100, the rewiring layer 510, the interlayer dielectric layer 500, and the metal Bump 520.

[0076] Based on the method in embodiment 2, the manufacturing method of the present embodiment is described as follows:

[0077] After step S105 is performed according to the method of Embodiment 2, a redistribution layer (RDL) 510 and metal bumps 520 are formed on the first surface 100 - 1 of the substrate 100 .

[0078] First, the dielectric layer on the first surface 100 - 1 is removed by appropriate methods such as etching, and the metal layer 330 and the barrier layer 320 are patterned to form a rewiring layer electrically connected to the deep hole 300 .

[0079] Subsequently, an interlayer dielectric layer 500 is formed on the first surface 100-1 of the substrate. The material of the interlayer dielectric layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com