Composite multifunctional anti-counterfeiting mark manufactured by utilizing laser etching

A technology of anti-counterfeiting marks and laser engraving, which is applied in the fields of anti-counterfeiting marks and anti-counterfeiting stamps, which can solve the problems of increasing production costs, inconvenient use, and small scope of application, and achieve the effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

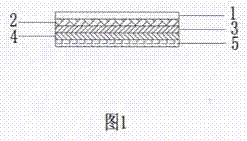

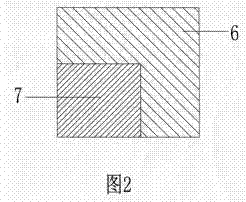

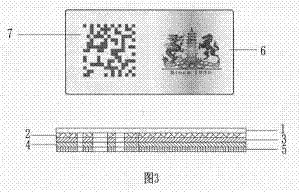

[0034] refer to figure 1 , 2 3. The two-dimensional code identification area of the anti-counterfeiting label in this embodiment is located on the left side of the optically variable image area, which can accommodate more optically variable images and make the information complete. It includes the following parts: from the structural distinction, it is divided into thin films Layer 1, peeling layer 2, molded layer 3, aluminum layer 4, glue layer 5, wherein film layer 1 uses high-quality PET film as raw material, molded layer 3 and aluminum layer 4 are divided into two parts respectively, from the front View distinction, divided into optically variable image 6 and laser-etched pattern 7 set on the background pattern. The optically variable image area is set with various anti-counterfeiting elements such as corporate LOGO and anti-counterfeiting information images, etc., and the laser-etched pattern area Due to the need for laser etching processing, and in order to ensure the...

Embodiment 2

[0038] refer to figure 1 , 2 , 3. The structure of the anti-counterfeiting mark in this embodiment is the same as that in Embodiment 1, the difference is that the large roll of foil is directly used for laser etching during production, and the large roll of foil is cut after the etching is completed, and then For hot stamping.

[0039] In this embodiment, the image, text or symbol laser etched on the background pattern of the anti-counterfeit mark is clear, and the processing precision is high, and the original background pattern of the laser etched image, text or symbol area also has anti-counterfeiting function, and the high Anti-counterfeiting performance, realizing multi-functional purposes such as anti-counterfeiting, marketing promotion, market information collection, product tracking, etc.

Embodiment 3

[0041] refer to figure 1 , 2 4. The two-dimensional code identification area of the anti-counterfeit label in this embodiment is located at any of the upper left, lower left, upper right, and lower right corners of the optically variable image area, and the anti-counterfeit label can be reduced as a whole, which is the position of various information It is more compact and includes the following parts: In terms of structure, it is divided into film layer 1, peeling layer 2, molded layer 3, aluminum layer 4, glue layer 5, of which film layer 1 uses high-quality PET film as raw material, and molded layer 3 and the aluminum layer 4 are divided into two parts, which are distinguished from the front view, and are divided into an optically variable image 6 and a laser-etched pattern 7 set on the background pattern. The optically variable image area is provided with various anti-counterfeiting elements as required The corporate LOGO and anti-counterfeiting information patterns, et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com