Cassegrain type light beam synthesizer with high duty ratio

A Cassegrain type and beam synthesis technology, which is applied in optics, optical components, instruments, etc., can solve the problems of compact structure, low beam duty ratio, and strict requirements on the size of supporting devices, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

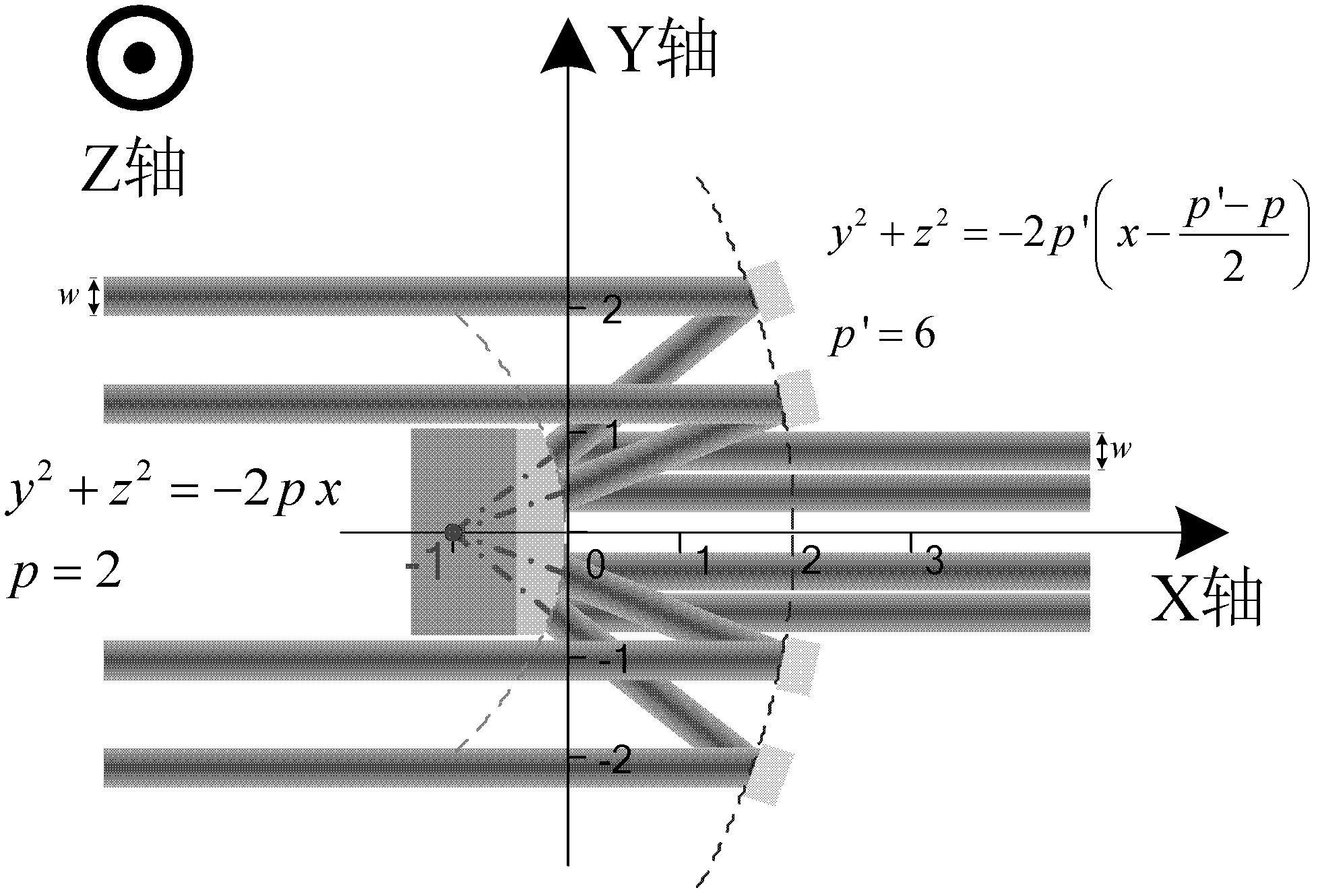

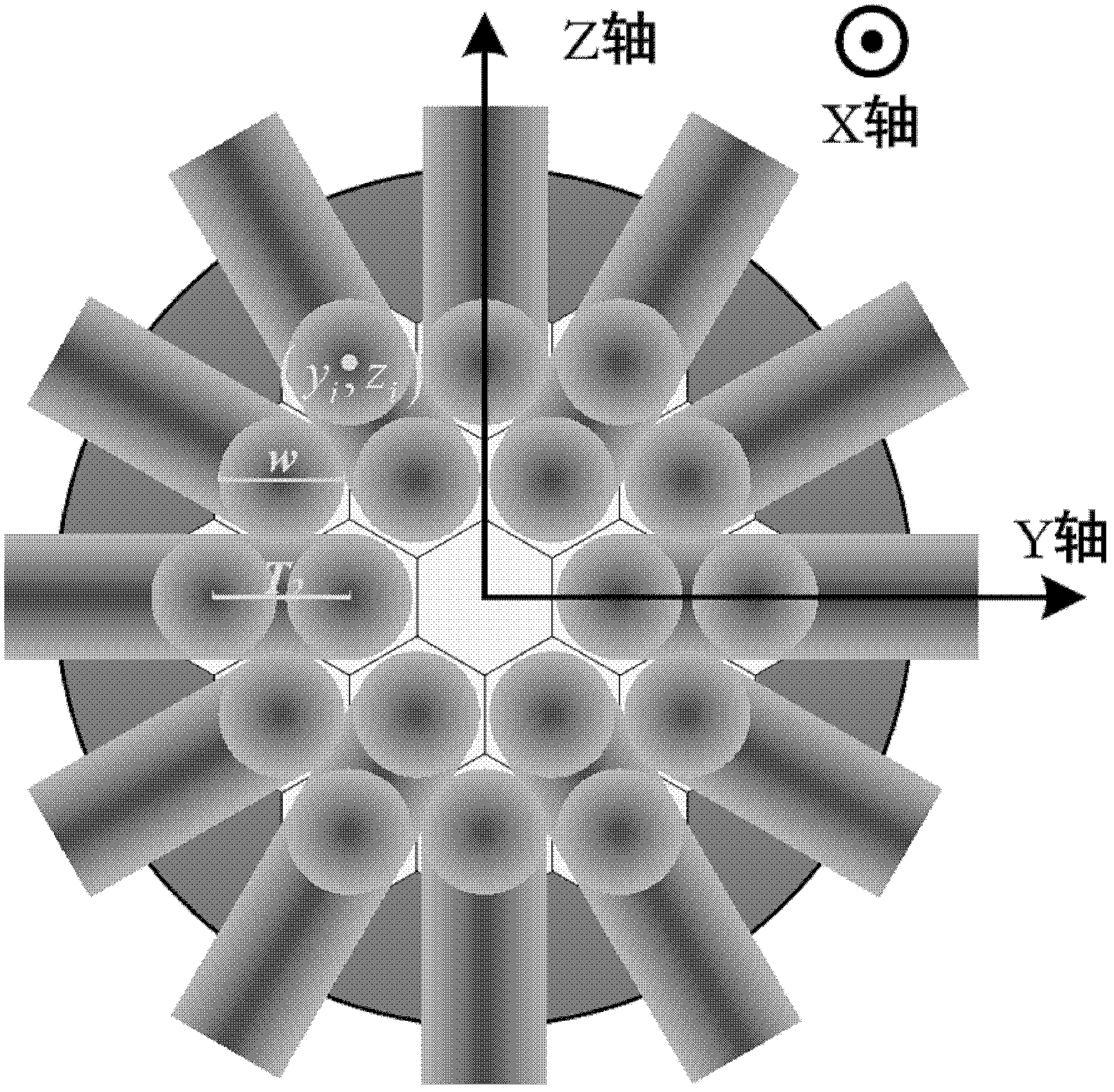

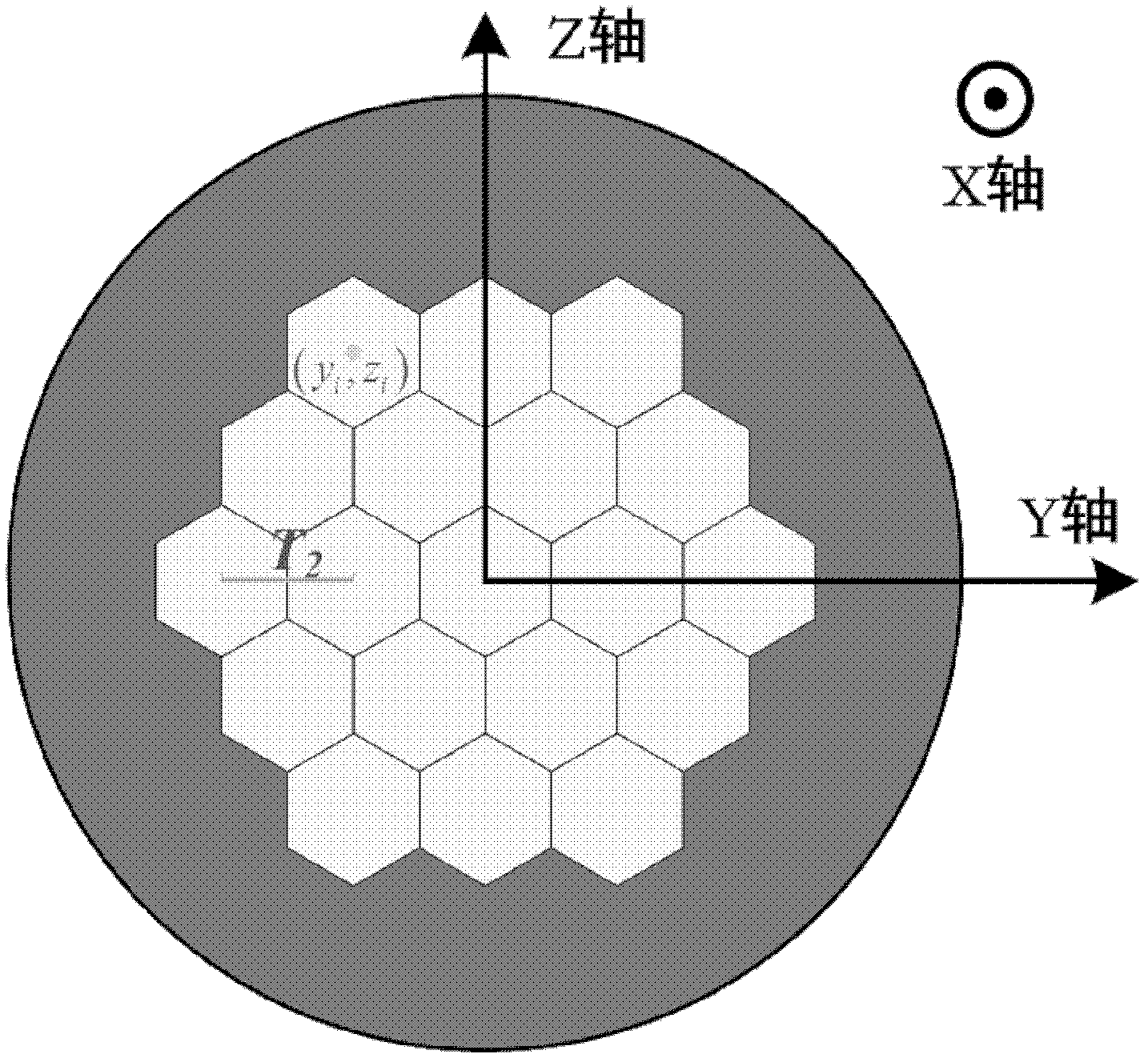

[0042] Since both the incident reflector and the exit reflector are plane mirrors, the beam combiner does not change the width of the beam (set as w), but only compresses the distance between the beams. The reflectors of the beam combining device are arranged according to a rotating parabola to form a Cassegrain beam conversion system. Each outgoing reflector is ground and polished on a cone whose surface is a rotating paraboloid; each incident reflector is a separate plane reflector, and its position and angle are determined by the corresponding outgoing reflector. The specific implementation plan is as follows:

[0043] 1. According to the beam width w and the number of beam paths N, make a reflector substrate whose surface shape is a rotating paraboloid. Place the substrate in the three-dimensional right-angled right-handed system O-XYZ so that its symmetry axis coincides with the X axis, and the apex is located at at the origin of the coordinates. Among them, the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com