Hydraulic prop capable of outputting constant force and repressing method

A technology of hydraulic prop and constant force output, applied in props/supports, earth-moving drilling, mining equipment, etc., can solve the problems of landslide, poor supporting effect, and reduced leakage of hydraulic props.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

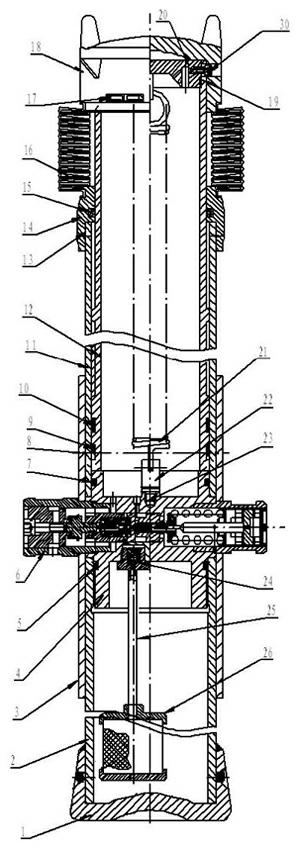

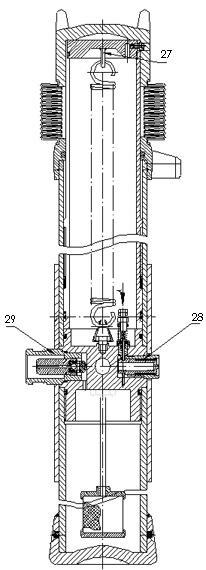

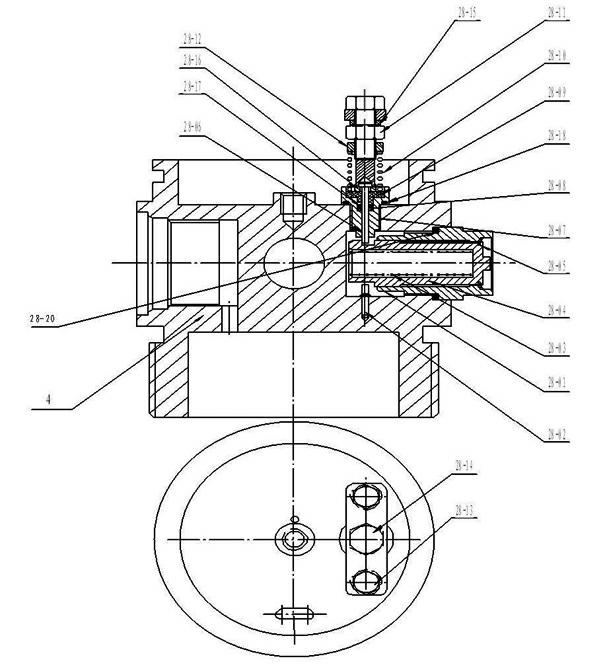

[0038] Such as figure 1 , figure 2 As shown, the pillar in the hydraulic support with constant force output includes at least the lower cylinder 2, the upper cylinder 11, the connecting hoop 3, the filling valve 28, the multi-purpose valve 6, the piston rod 12, the alarm device 28, the one-way Valve 24 and Manifold 4.

[0039] The lower cylinder 2 is connected to the integrated block 4 by threads, the upper cylinder 11 is placed on the upper end of the integrated block 4, the lower cylinder 2, the integrated block 4, and the upper cylinder 11 are connected into one body through the connecting hoop 3, and the piston rod 12 is connected to the upper cylinder 11. Inside, the piston rod 12 and the upper cylinder 11 are sealed by the Y-shaped sealing ring 9, the upper end of the piston rod 12 is connected to the top cover 18, the lower end of the lower cylinder 2 is fixedly seated on the base 1, and the upper end of the upper cylinder 11 has a guide hoop 14, Guide hoop traveler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com