MOCVD (Metal-organic Chemical Vapor Deposition) system with multiple extensional reaction cavities and operation method thereof

An operation method and reaction chamber technology, applied in the field of MOCVD systems, can solve the problems of inability to meet the needs of large-scale epitaxial substrate production, increase costs and operating costs, and low output, so as to prolong the cleaning and maintenance cycle, shorten the Preparation time, the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

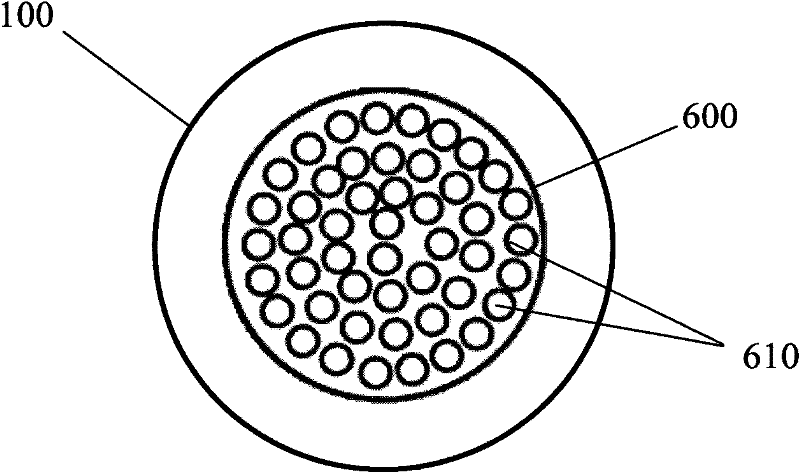

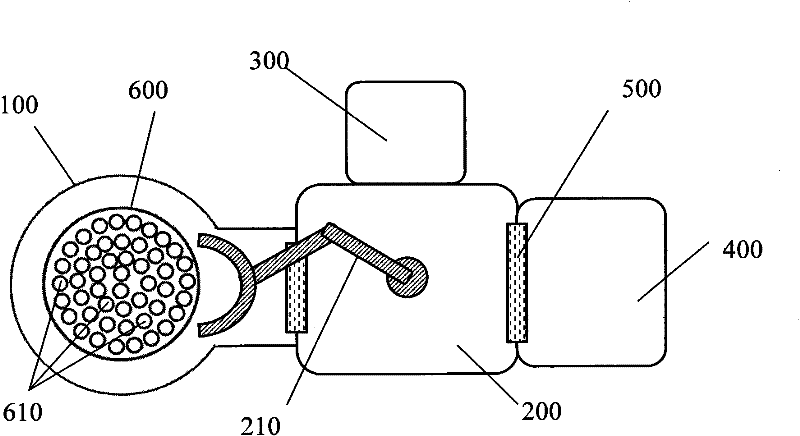

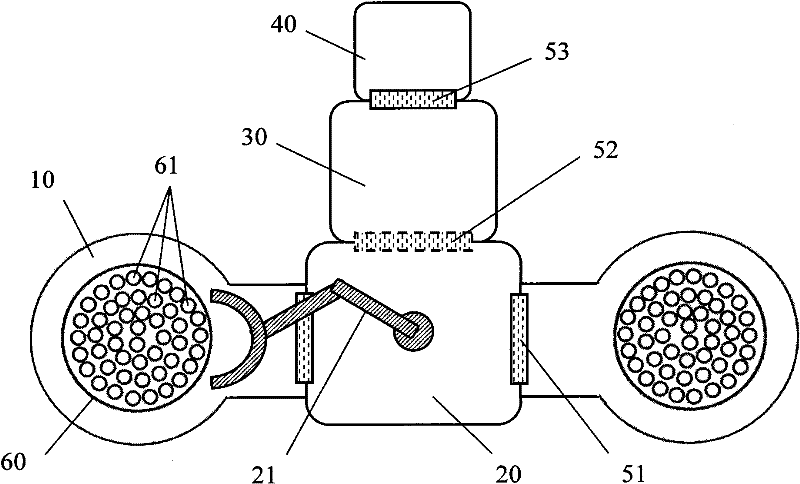

[0054] Please refer to image 3 , Figure 4 As shown, the MOCVD system with multiple epitaxial reaction chambers involved in this embodiment includes a transfer chamber 20 provided with a manipulator 21, and equal to or more than two epitaxial reaction chambers 10 connected to the transfer chamber 20, and also includes a A transfer station 30 connected to the transfer chamber 20 , and a loading and unloading platform 40 connected to the transfer station 30 . A vacuum isolation valve 51 is provided between the transfer chamber 20 and each epitaxial reaction chamber 10; a vacuum isolation valve 52 is provided between the transfer chamber 20 and the transfer station 30, and a vacuum isolation valve 53 is provided between the transfer station 30 and the loading and unloading station 40 .

[0055] Such as image 3 Shown is an MOCVD system with two epitaxial reactor chambers; Figure 4 Shown is an MOCVD system with three epitaxial reactor chambers. The maximum number of epitaxi...

Embodiment 2

[0064] Such as Figure 5 As shown, the MOCVD system involved in this embodiment is configured with two epitaxial reaction chambers 10 as an example, which is similar in structure to the above embodiment, including a transfer chamber 20 provided with a manipulator 21, and a transfer chamber 20 connected to Two epitaxial reaction chambers 10 . The difference is that it also includes two transfer stations 30 connected to the transfer chamber 20 , and each transfer station 30 is also connected to a loading and unloading platform 40 .

[0065] Similar to the above embodiments, a vacuum isolation valve 51 is provided between the transfer chamber 20 and each epitaxial reaction chamber 10 ; a vacuum isolation valve 53 is provided between the transfer station 30 and the loading and unloading station 40 . The vacuum isolation valve 52 between the transfer chamber 20 and the transfer station 30 ( Figure 5 Indicated by the dotted line) can be set or removed according to requirements. ...

Embodiment 3

[0070] Such as Figure 6 As shown, this embodiment relates to a MOCVD system with multiple epitaxial reaction chambers, which is similar in structure to the above embodiment, including a transfer chamber 20 provided with a manipulator 21, and several transfer stations 30 connected to the transfer chamber 20 and multiple An epitaxial reaction chamber 10.

[0071] The difference lies in that the transfer chamber 20 in this embodiment is polygonal, so that it can be connected with more epitaxial reaction chambers 10 or transfer stations 30 . by Figure 6 As an example, the transfer chamber 20 is hexagonal, and it is respectively connected with two transfer stations 30 and three epitaxial reaction chambers 10 ; each transfer station 30 is also connected with a loading and unloading station 40 .

[0072] Similar to the above embodiments, a vacuum isolation valve 51 is provided between the transfer chamber 20 and each epitaxial reaction chamber 10 ; a vacuum isolation valve 53 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com