Thermal pyrolysis combination method and device

A pyrolysis gasification and combined device technology, which is applied in the field of coal chemical industry, can solve the problems of low calorific value and achieve the effects of low tar content, high calorific value of gas and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

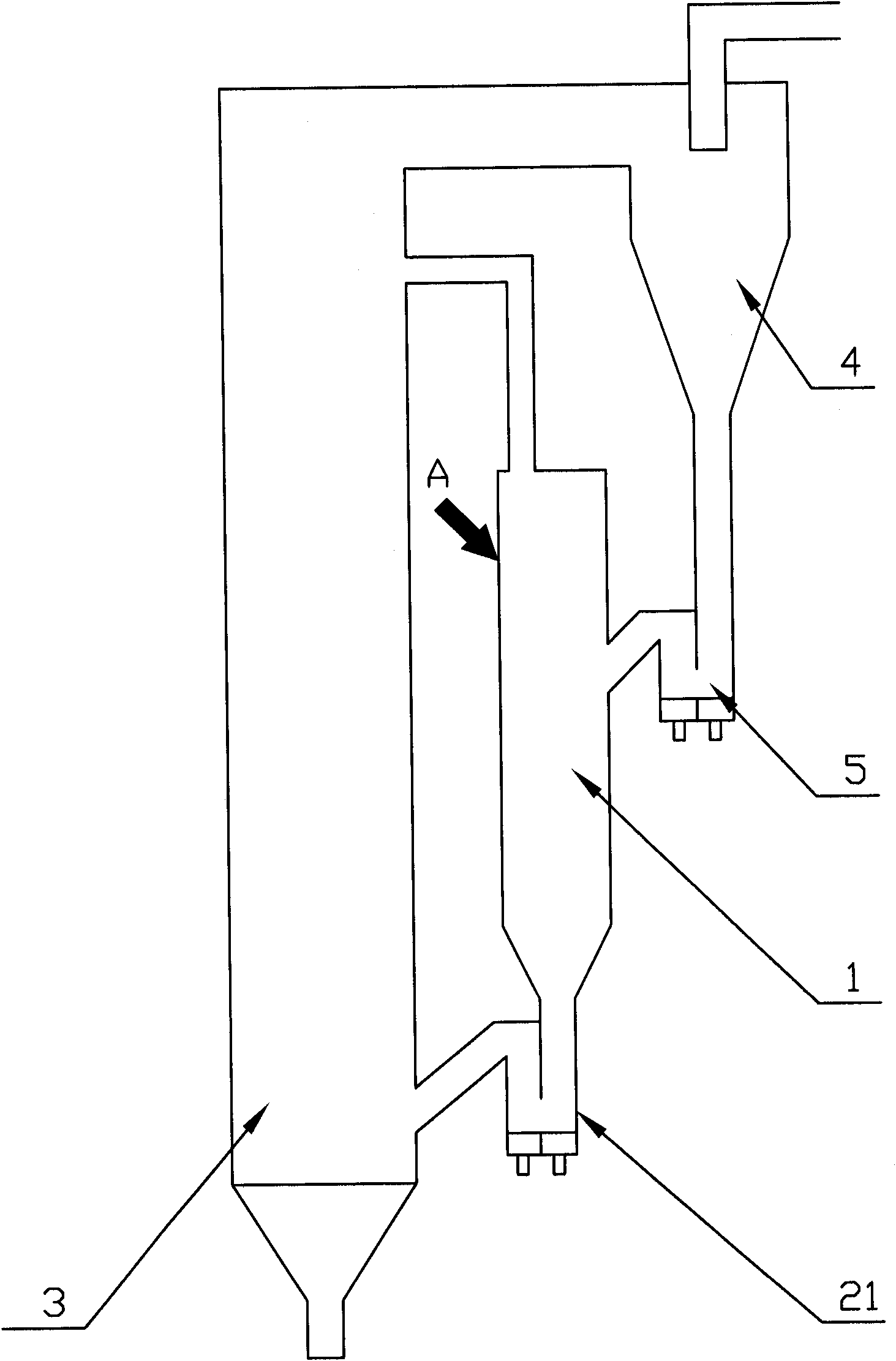

Embodiment 1

[0043] Such as figure 1 In the pyrolysis and gasification combined method and device of the present invention shown, the coal is sent to the low-speed bed pyrolysis furnace for pyrolysis, and the semi-coke produced is sent to the circulating fluidized bed gasification chamber for gasification; the cyclone separator collects The solid particles are sent into the pyrolysis furnace as a solid heat carrier to provide heat for coal pyrolysis; the gasification temperature of the gasification furnace is 900°C, and the pyrolysis temperature of the pyrolysis furnace is 800°C. The gas is passed into the upper part of the gasifier to crack the tar in the pyrolysis gas and trap the solid particles in the pyrolysis gas and coal gas; the solid heat carrier is sent into the thermal Above the dense phase area of the pyrolysis furnace; the semi-coke produced by the pyrolysis furnace is sent from the bottom of the pyrolysis furnace to the lower part of the gasifier.

[0044] Such as figure ...

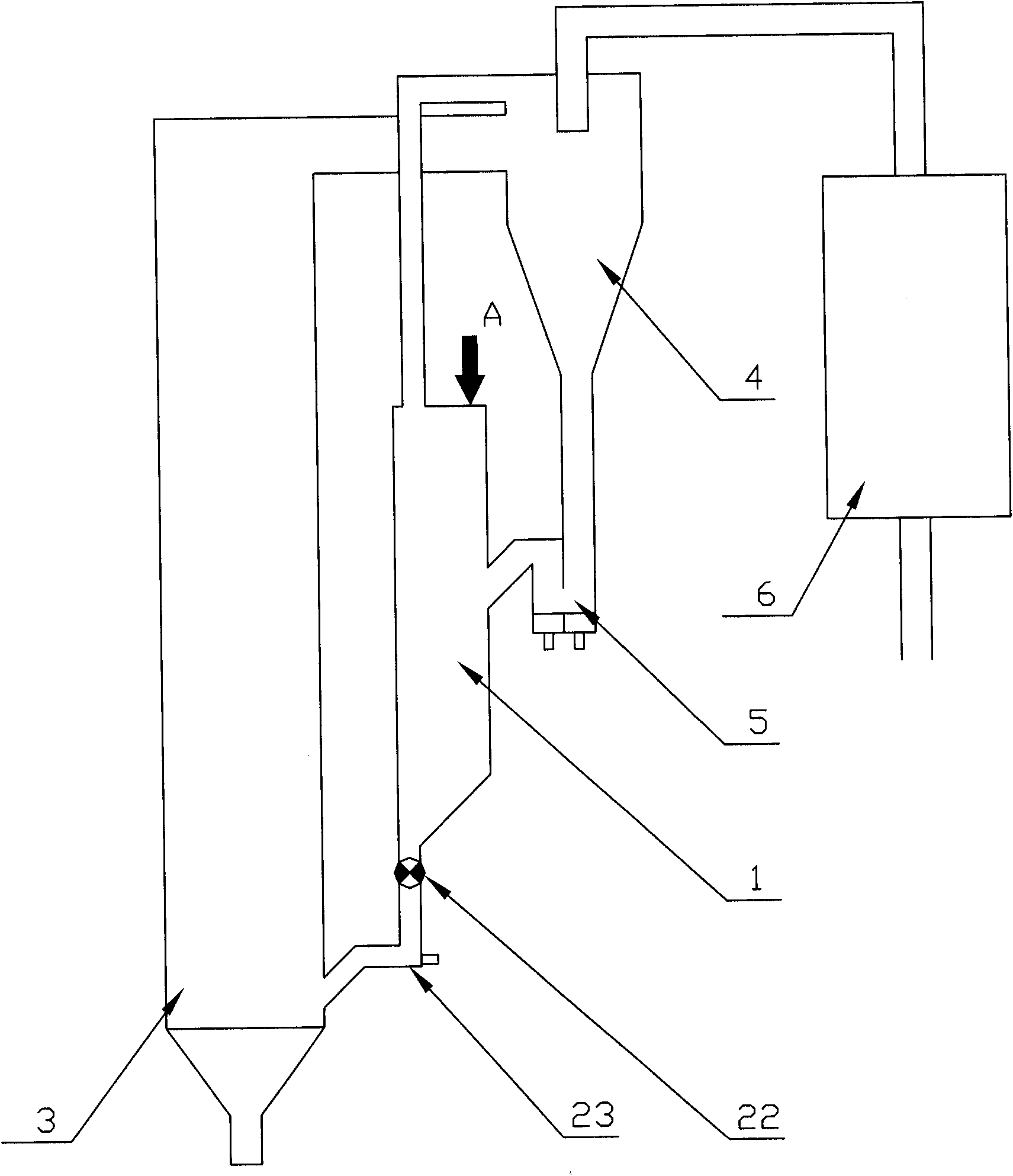

Embodiment 2

[0046] Such as figure 2 In the pyrolysis and gasification combined method of the present invention shown, the biomass is sent to the low-speed bed pyrolysis furnace for pyrolysis, and the semi-coke produced is sent to the circulating fluidized bed gasification chamber for gasification; the cyclone separator traps Solid particles are sent into the pyrolysis furnace as a solid heat carrier to provide heat for biomass pyrolysis; the gasification temperature of the gasification furnace is 1000°C, and the pyrolysis temperature of the pyrolysis furnace is 900°C. The gas and the gas produced by the gasifier are passed into the cyclone separator together to crack the tar in the pyrolysis gas and capture the solid particles in the pyrolysis gas and coal gas; The middle part of the furnace side wall is sent to the top of the dense phase area of the pyrolysis furnace; the semi-coke produced by the pyrolysis furnace is sent to the lower part of the gasifier from the bottom of the pyrol...

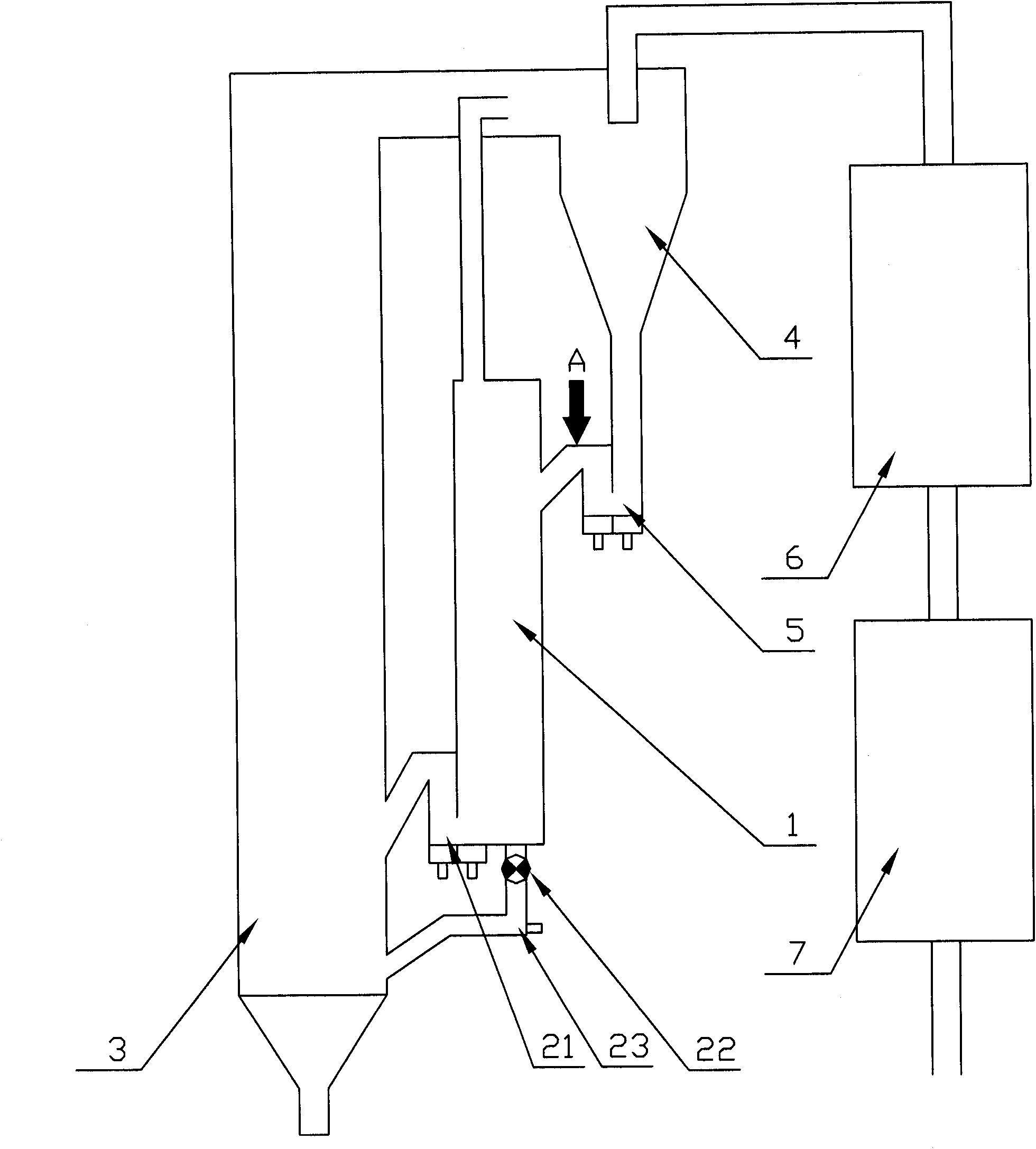

Embodiment 3

[0050] Such as image 3 In the pyrolysis and gasification combined method of the present invention shown, the coal is sent to the low-speed bed pyrolysis furnace for pyrolysis, and the semi-coke produced is sent to the circulating fluidized bed gasification chamber for gasification; the solids captured by the cyclone separator Particles are sent into the pyrolysis furnace as a solid heat carrier to provide heat for coal pyrolysis; the gasification temperature of the gasification furnace is 1200°C, and the pyrolysis temperature of the pyrolysis furnace is 1000°C. The pyrolysis gas produced by the pyrolysis furnace and The coal gas produced by the gasification furnace is passed into the cyclone separator together to crack the tar in the pyrolysis gas and capture the solid particles in the pyrolysis gas and coal gas; The middle part of the wall is sent to the upper part of the dense phase area of the pyrolysis furnace; the semi-coke produced by the pyrolysis furnace is sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com