Modified anhydrous calcium sulfate and preparation method thereof

A technology of anhydrous calcium sulfate and calcium sulfate, which is applied in the treatment of dyed low-molecular organic compounds and fibrous fillers, etc. It can solve the problem of poor interface bonding performance between calcium sulfate powder and polymer materials, and poor mechanical properties of materials, etc. problem, to achieve the effect of easy adhesion and good surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

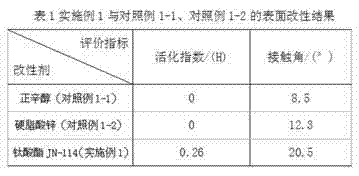

Embodiment 1

[0016] The modified anhydrous calcium sulfate of the present embodiment is made from the following raw materials in parts by weight: calcium sulfate powder 7Kg, titanate coupling agent JN-114 3Kg; Products obtained by hydrothermal synthesis.

[0017] Preparation:

[0018] (1) Place the calcium sulfate powder in a constant temperature oven and dry it at 50°C for 2 hours to remove the physically adsorbed water on the surface of the calcium sulfate powder;

[0019] (2) Dissolve the calcium sulfate powder dried in step (1) in water to prepare a suspension of calcium sulfate powder with a mass concentration of 40%, heat and stir in a water bath for 5 hours, and the temperature of the water bath is 60°C;

[0020] (3) Stir the coupling agent and absolute ethanol with a mass ratio of 1:10 at 45°C for 5 hours, filter with suction 5 times, and take the filtrate until the impurities are removed; then add the titanate coupling agent-ethanol solution Add to the calcium sulfate powder sus...

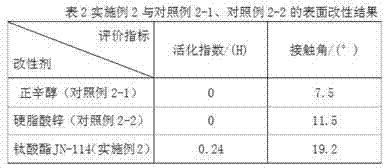

Embodiment 2

[0029] The modified anhydrous calcium sulfate of the present invention is made of the following raw materials in parts by weight: calcium sulfate powder 8Kg, titanate coupling agent JN-114 2Kg; the calcium sulfate powder used is natural gypsum as raw material, and water Products obtained by thermosynthesis.

[0030] Preparation:

[0031] (1) Place the calcium sulfate powder in a constant temperature oven and dry it at 50°C for 2 hours to remove the physically adsorbed water on the surface of the calcium sulfate powder;

[0032] (2) Dissolve the calcium sulfate powder dried in step (1) in water to prepare a suspension of calcium sulfate powder with a mass concentration of 50%, heat and stir in a water bath for 6 hours, and the temperature of the water bath is 60°C;

[0033] (3) Stir the coupling agent and absolute ethanol with a mass ratio of 1:10 at 45°C for 6 hours, filter with suction 5 times, and take the filtrate until the impurities are removed; then add the titanate cou...

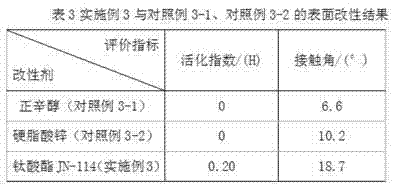

Embodiment 3

[0042] The modified anhydrous calcium sulfate of the present invention is made of the following raw materials in parts by weight: calcium sulfate powder 9Kg, titanate coupling agent JN-114 1Kg;

[0043] The calcium sulfate powder used is a product obtained by using natural raw gypsum as a raw material and adopting a hydrothermal synthesis method.

[0044] Preparation:

[0045] (1) Place the calcium sulfate powder in a constant temperature oven and dry it at 50°C for 5 hours to remove the physically adsorbed water on the surface of the calcium sulfate powder;

[0046] (2) Dissolve the calcium sulfate powder dried in step (1) in water to prepare a suspension of calcium sulfate powder with a mass concentration of 60%, heat and stir in a water bath for 7 hours, and the temperature of the water bath is 60°C;

[0047] (3) Stir the coupling agent and absolute ethanol with a mass ratio of 1:10 at 45°C for 7 hours, filter with suction 5 times, and take the filtrate until the impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com