Vehicle brake mechanism and method for controlling the vehicle brake mechanism

The technology of a braking device and a control method, which is applied in the direction of a braking transmission device, a braking action starting device, a brake, etc., can solve problems such as loss of braking force of a wheel cylinder, complicated structure of a slave cylinder, etc., and achieve the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

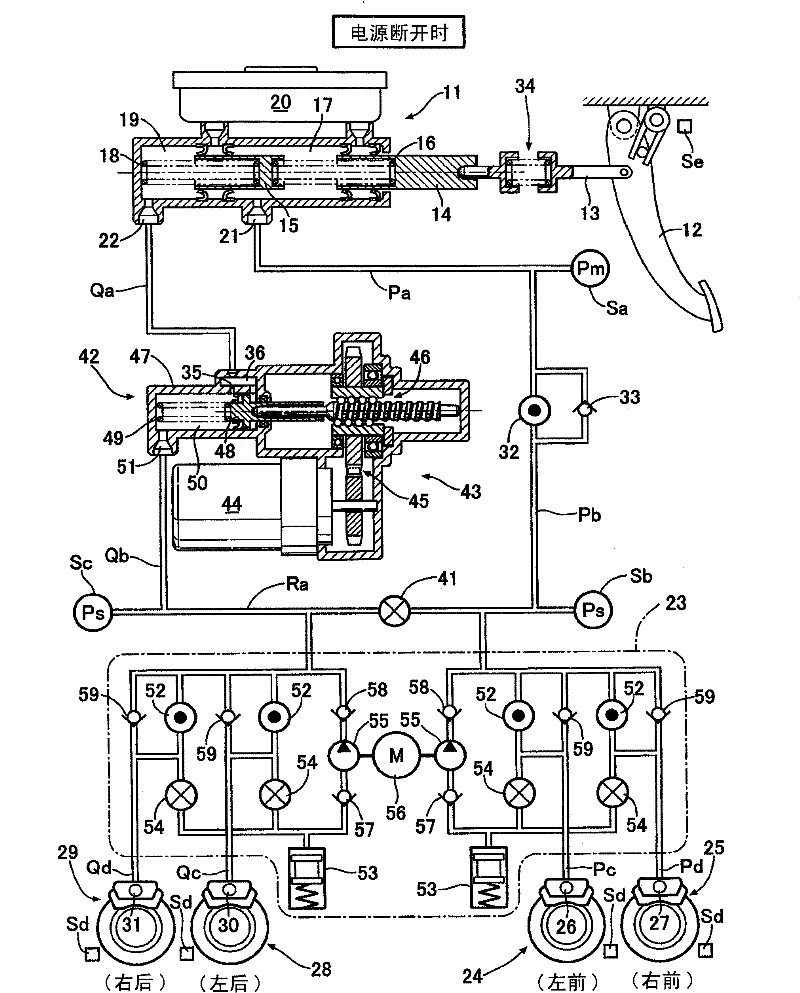

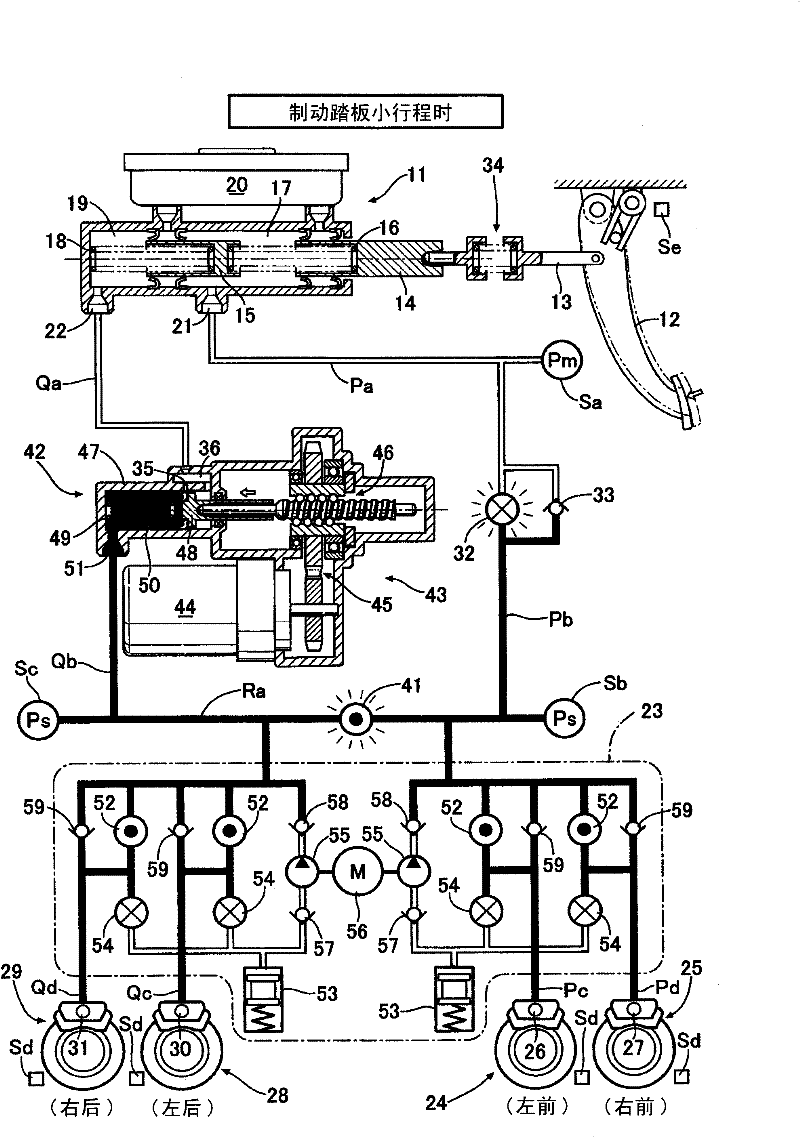

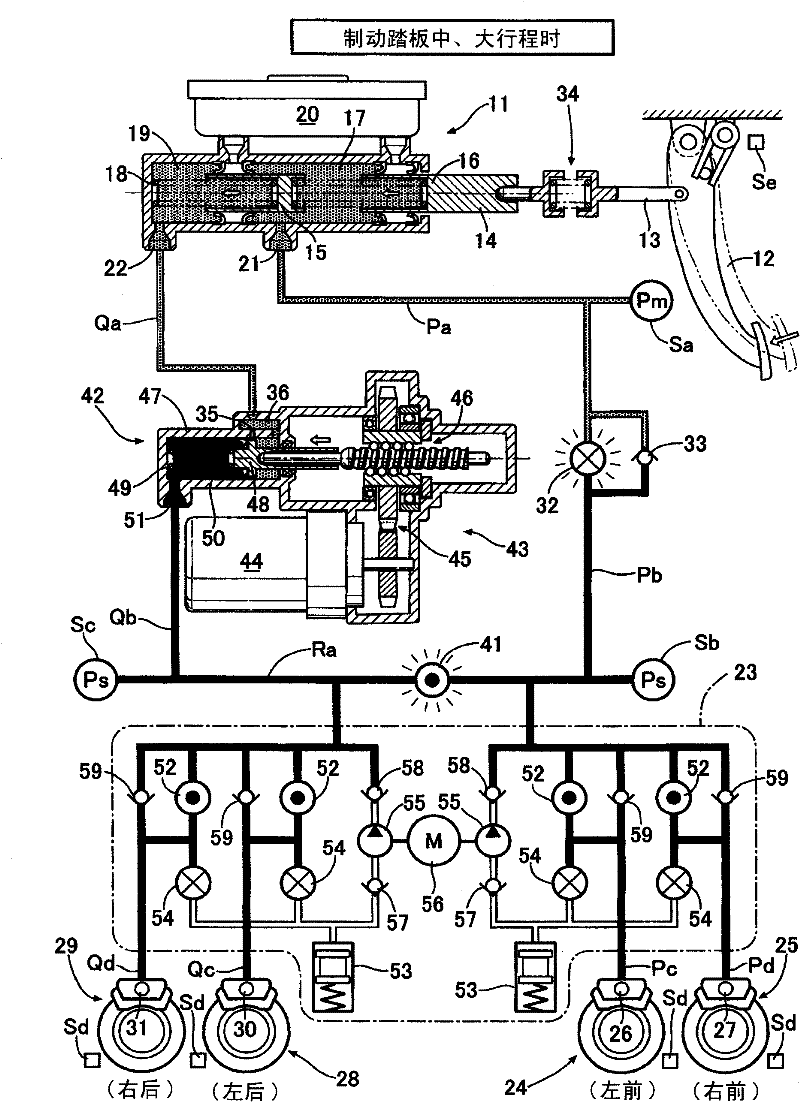

[0049] Below, based on Figure 1 to Figure 7 , to describe the embodiment of the present invention.

[0050] Such as figure 1 As shown, the tandem master cylinder 11 is equipped with a first piston 14 connected to the brake pedal operated by the driver via a push rod 13 and a second piston 15 arranged in front of it, and is divided into the first piston 14 and the second piston. A first hydraulic chamber 17 in which a return spring 16 is accommodated between the pistons 15 , and a second hydraulic chamber 19 in which a return spring 18 is accommodated in front of the second piston 15 . A stroke simulator 34 made of a spring is disposed at an intermediate position of the push rod 13 .

[0051] The first hydraulic chamber 17 and the second hydraulic chamber 19, which can communicate with the liquid storage chamber 20, respectively have a first output port 21 and a second output port 22. The first output port 21 is a normally open electromagnetic valve through the liquid path P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com