Production method of super-thin diamond frame saw blade matrix

A production method and diamond technology, applied in metal sawing equipment, tool manufacturing of sawing machine devices, metal processing equipment, etc., can solve the problems of insufficient rigidity and toughness of materials, and achieve the effect of reducing the consumption of steel resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] (1) Selection of material components used in the matrix: by weight percentage: C 0.75-0.85; Si<0.35; Mn<0.50; Cr0.20-0.50; S<0.030; P<0.030; Ni 1.30-2.00; the balance is iron .

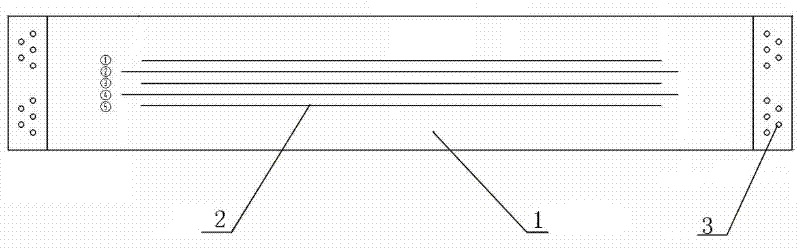

[0025] (2) Material preparation: According to the material preparation of the substrate 1 in step (1), the prepared material is prepared according to the different specifications of the saw blade, and the substrate blank of the specified size is prepared; the specifications of the finished product in this example: the length is 4100mm, the width is 180mm, and the thickness is 1.8 mm. According to the specification requirements of the frame saw blade base body, prepare the blank of the frame saw blade base body with the specified size.

[0026] (3) Tension treatment: adjust the rolling position and pressure on the frame saw blade rolling machine, and control the pressure of No. 1, No. 3, and No. 5 rolling bars to 28-30kgf / cm 2 , No. 2, No. 4 rolling bar pressure 32 ~ 35kgf / cm 2 According to F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com