Spraying granulation flue gas treatment system and process

A technology of spraying granulation and flue gas, which is applied in the field of air pollution control and can solve problems such as burnt smell of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

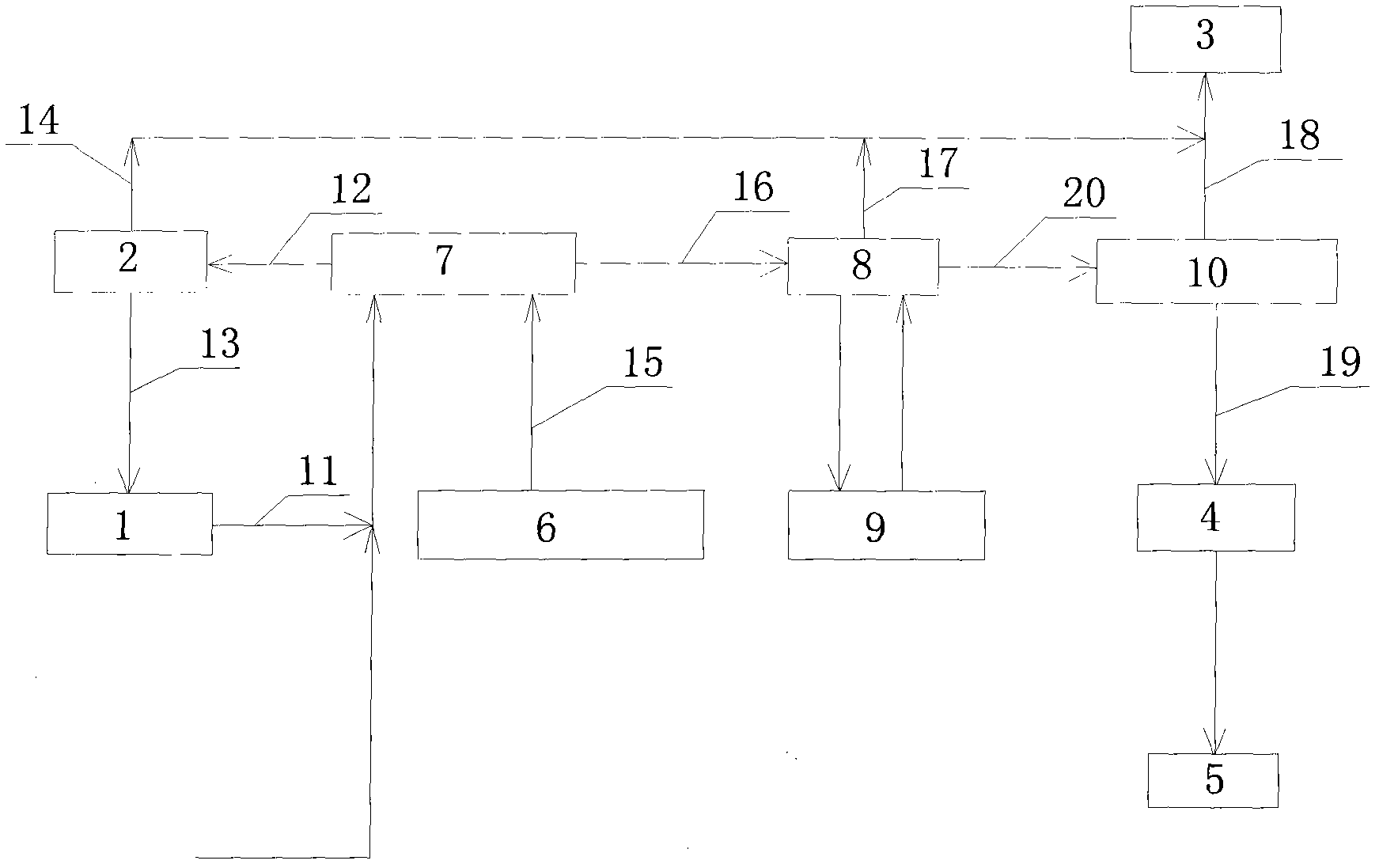

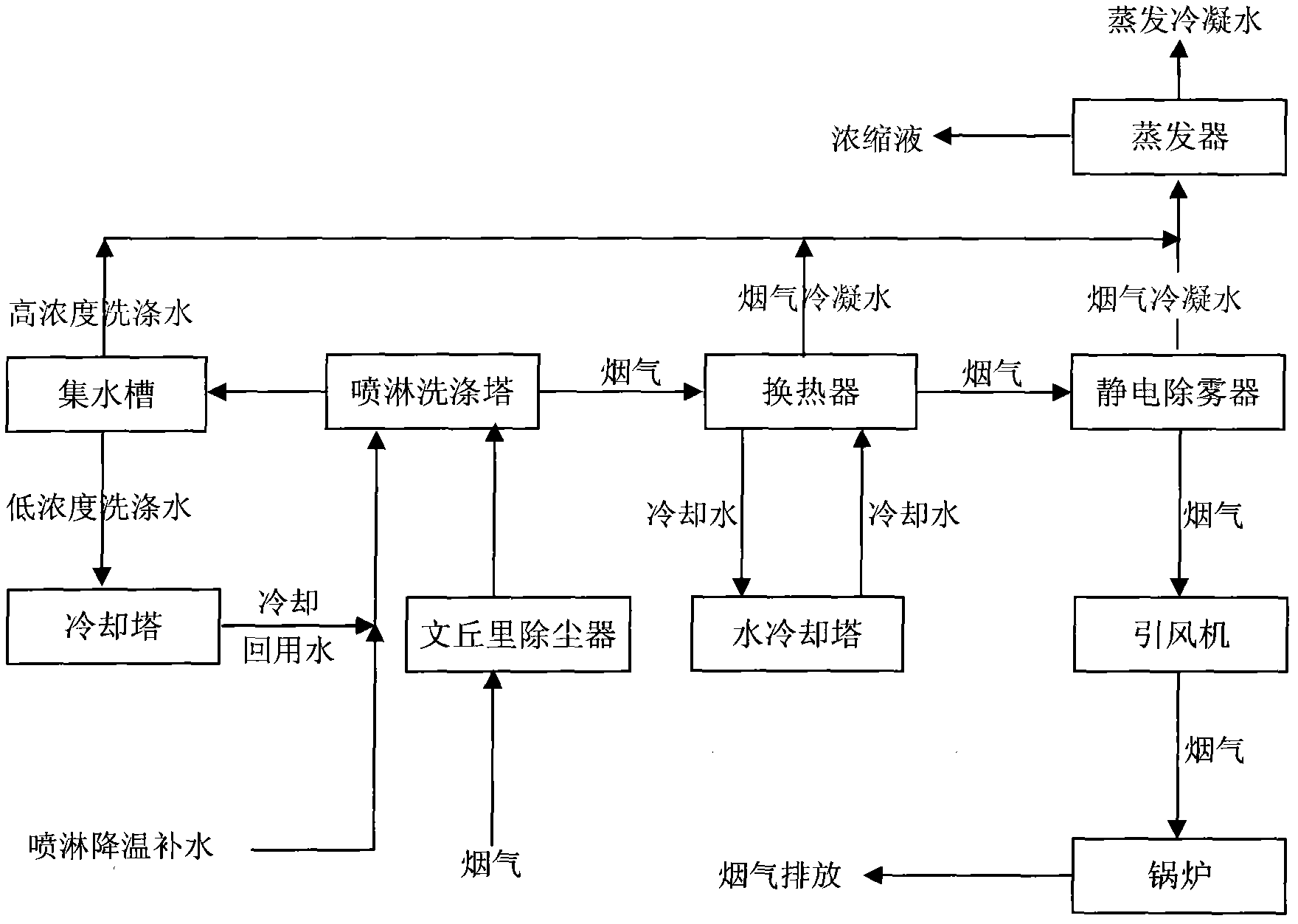

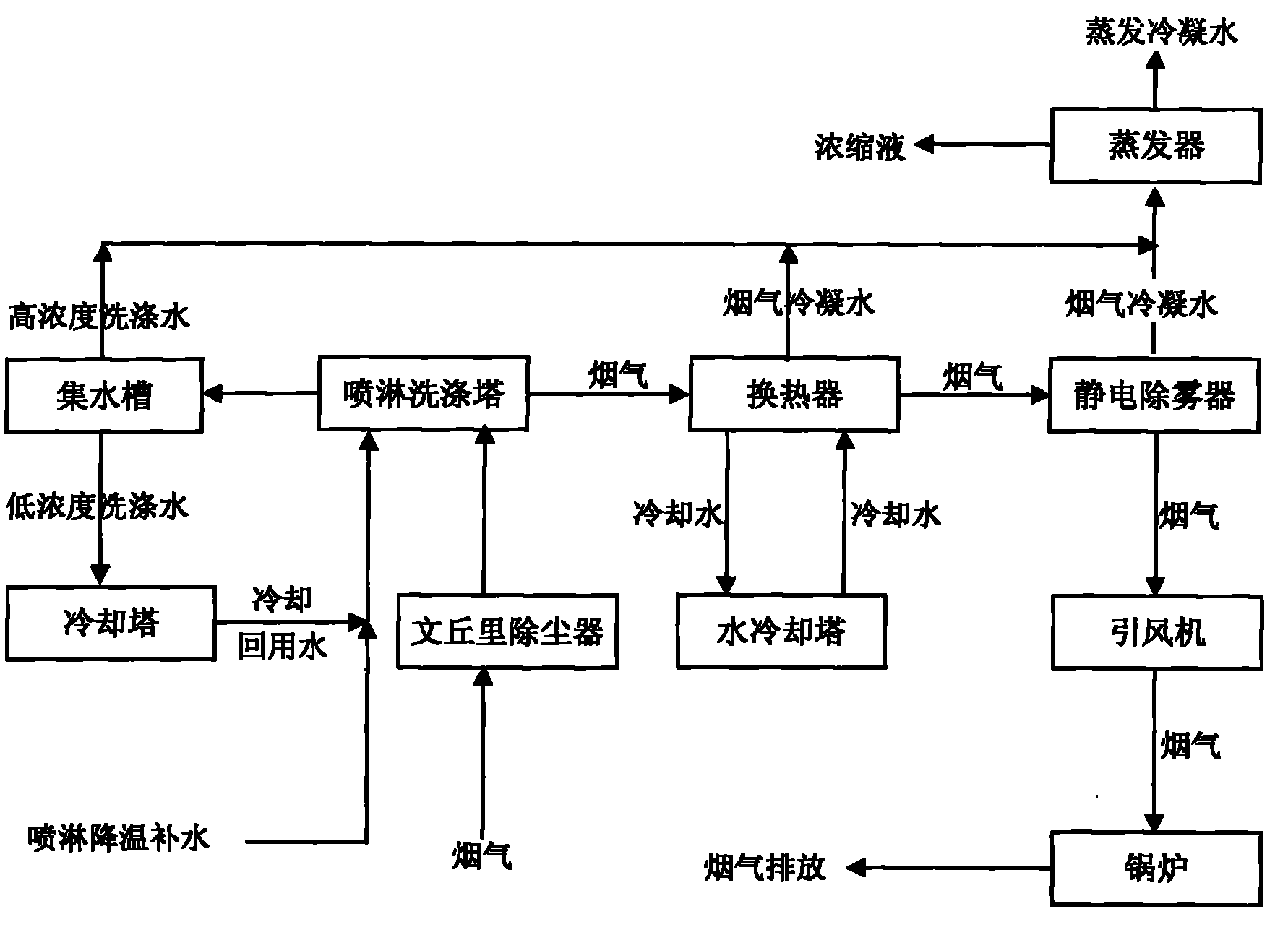

[0017] Example 1: A spray granulation flue gas treatment system includes a cooling tower 1, a water collection tank 2, an evaporator 3, an induced draft fan 4, a boiler 5, a Venturi dust collector 6, a spray washing tower 7, and a heat exchanger 8. The water cooling tower 9, the electrostatic demister 10, the induced draft fan 4 are connected to the boiler 5, wherein the outlet pipe 11 of the cooling tower 1 is connected to the spray scrubber 7, and the outlet pipe 12 of the spray scrubber 7 is connected to the sump 2 The water inlet pipe of the sump 2 is connected to the low-concentration washing water outlet pipe 13 of the cooling tower 1, the high-concentration washing water outlet pipe 14 of the sump is connected to the evaporator 3, and the Venturi dust collector 6 is connected to the spray washing The flue gas pipe 15 of the tower 7 is connected, the flue gas pipe 16 of the spray scrubber 5 is connected with the heat exchanger 8, the heat exchanger 8 and the water cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com