Photosensitive composition for volume hologram recording and method for producing same

A technology of photosensitive composition and manufacturing method, which is applied in the direction of hologram recording material, optical recording carrier manufacturing, holographic process, etc., can solve the problem that the volume change polymerization reactivity of photosensitive composition for holography may not be satisfied, and achieve Excellent refractive index modulation capability, excellent reproducibility, and high polymerization reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited to these examples.

[0112] (optical system)

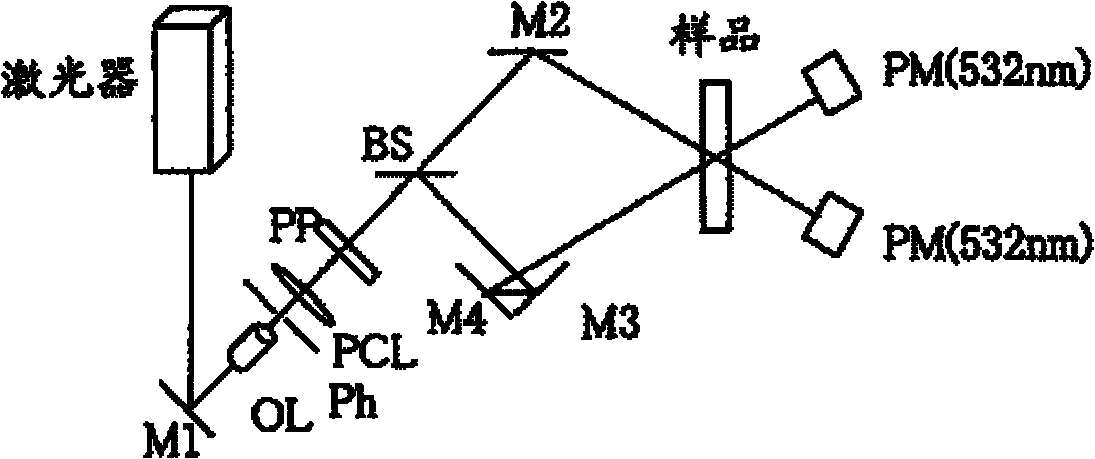

[0113] figure 1 Shown is a schematic diagram of the optical system used in the experiment. As a light source, a 532nm semiconductor laser is used, which is split into two beams by a beam splitter (BS) through a mirror (M), a spatial filter (OL and Ph), a plano-convex lens (PCL), and a wave blocking plate (PP). The two beams of light separated from the BS are incident on the sample at 30° and 30° respectively through the mirror and interfere. The intensities of diffracted light and transmitted light were detected using a power meter (PM: manufactured by ADC Corporation).

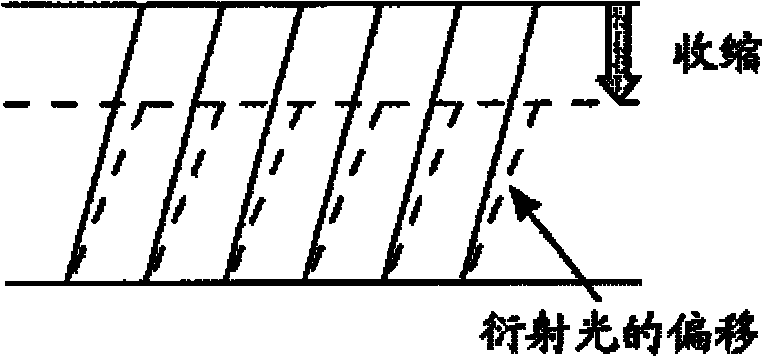

[0114] In addition, diffraction efficiency and shrinkage rate were calculated|required by the following method.

[0115] (diffraction efficiency)

[0116] The diffraction efficiency of the hologram recorded by the...

Embodiment X-1

[0128] Prepare 60 parts by weight of poly 2-vinylnaphthalene (Mw=93,000) as the binder polymer (A), which consists of a bifunctional alicyclic epoxy compound (3,4,3',4'-diepoxy Dicyclohexane) and bifunctional vinyl ether compound (oxanorbornene divinyl ether) mixed in a molar ratio of 7:1 cation polymerizable compound (B) 100 parts by weight, as photopolymerization initiator Diphenyl iodide of agent (C) 10 parts by weight of a compound (trade name "PI2074", manufactured by Rhodia Corporation) and 0.5 parts by weight of a coumarin-based pigment (trade name "NKX1658", manufactured by Hayashibara Biochemical Research Institute) as a sensitizing pigment (D), these The components were dissolved in 30 parts by weight of cyclohexanone, and the obtained solution was used as photosensitive liquid X-1. This photosensitive liquid X-1 was dropped onto a glass substrate, applied with a coater to a film thickness of 25 μm, and a frame with a thickness of 50 μm was provided on the surface ...

Embodiment X-2

[0130]Prepare 70 parts by weight of poly 2-vinylnaphthalene (Mw=93,000) as the binder polymer (A), which consists of a bifunctional cycloaliphatic epoxy compound (3,4,3',4'-diepoxy Dicyclohexane) and bifunctional vinyl ether compound (oxanorbornene divinyl ether) mixed in a molar ratio of 7:1 cation polymerizable compound (B) 100 parts by weight, as photopolymerization initiator Diphenyl iodide of agent (C) 10 parts by weight of a compound (trade name "PI2074", manufactured by Rhodia Corporation) and 0.5 parts by weight of a coumarin-based pigment (trade name "NKX1658", manufactured by Hayashibara Biochemical Research Institute) as a sensitizing pigment (D), these The components were dissolved in 280 parts by weight of cyclohexanone, and the obtained solution was used as photosensitive liquid X-2. This photosensitive solution X-2 was dropped onto a glass substrate, and applied using an applicator so that the film thickness after drying was 25 μm, and the solvent was sufficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com