Silicon nano wire-fullerene complex cathode material for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and silicon nanowires, applied in electrode manufacturing, battery electrodes, electrolytic inorganic material coatings, etc., can solve the problems of lower specific capacity of composite materials, no lithium storage capacity, etc., and achieve excellent cycle stability and charge-discharge High performance, high adjustability, simple and economical method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

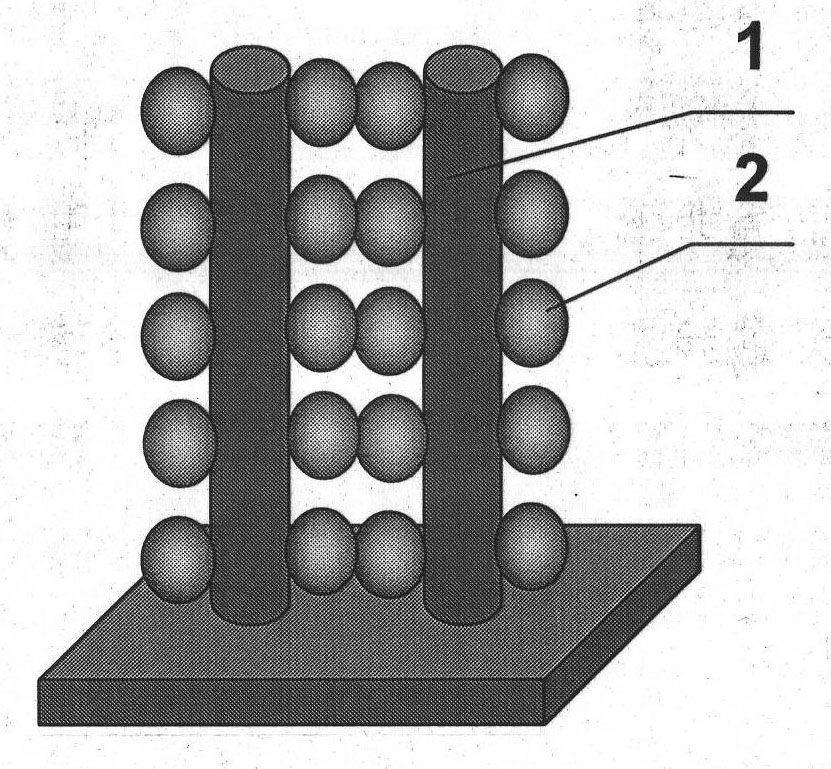

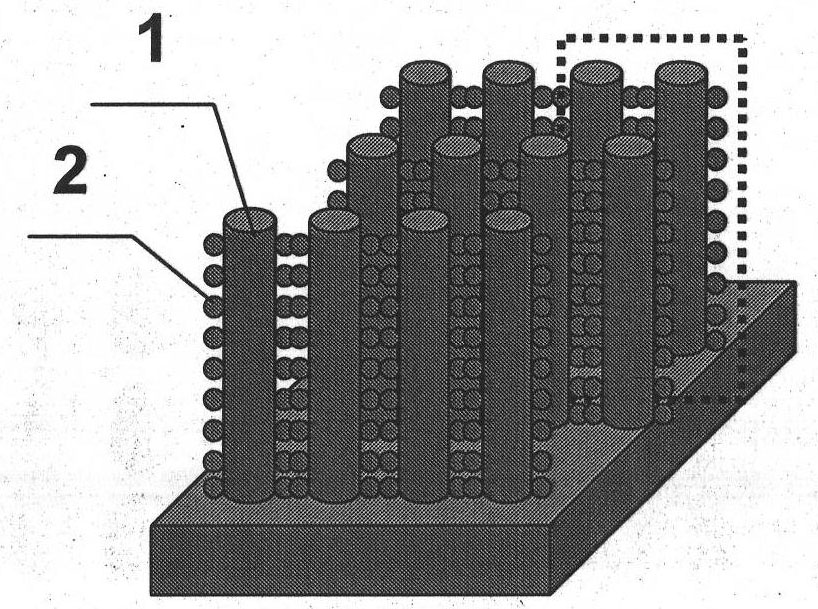

[0022] Clean the silicon wafer; soak the p-type [100] direction monocrystalline silicon wafer with a resistivity of 3-7Ω*cm in 30% H with a volume ratio of 1:3 2 o 2 : Concentrated H 2 SO 4 solution, the soaking time is about 20 minutes; then soak in 5% hydrofluoric acid solution for about 5 minutes; coat a layer of plastic glue on the unpolished surface of the silicon wafer, and then deposit a layer of plastic glue on the silicon wafer by electroless deposition method. Layer of nano-silver particle film, the electroplating solution is 4.8M HF and 0.005M AgNO 3 Mix the solution for 1.5min; wash the silver-plated silicon chip with deionized water, and place it in 4.8M HF and 0.4M H 2 o 2 In the mixed solution, react at a constant temperature of 50°C for 60 minutes; put the corroded silicon chip into the acetone solution until the plastic glue on the back of the silicon chip falls off; finally use HNO 3 solution, HF solution and deionized water are washed and dried to obtai...

Embodiment 2

[0025] Clean the silicon wafer; soak the n-type [100] direction monocrystalline silicon wafer with a resistivity of 3-7Ω*cm in 30% H with a volume ratio of 1:3 2 o 2 : Concentrated H 2 SO 4 solution, the soaking time is about 20 minutes; then soak in 5% hydrofluoric acid solution for about 5 minutes; coat a layer of plastic glue on the unpolished surface of the silicon wafer, and then deposit a layer of plastic glue on the silicon wafer by electroless deposition method. Layer of nano-silver particle film, the electroplating solution is 4.8M HF and 0.005M AgNO 3 Mix the solution for 1.5min; wash the silver-plated silicon chip with deionized water, and place it in 4.8M HF and 0.4M H 2 o 2 In the mixed solution, react at a constant temperature of 50°C for 60 minutes; put the corroded silicon chip into the acetone solution until the plastic glue on the back of the silicon chip falls off; finally use HNO 3 solution, HF solution and deionized water are washed and dried to obtai...

Embodiment 3

[0028] Clean the silicon wafer; soak the p-type [100] direction monocrystalline silicon wafer with a resistivity of 0.01-0.2Ω*cm in 30% H with a volume ratio of 1:3 2 o 2 : Concentrated H 2 SO 4 solution, the soaking time is about 20 minutes; then soak in 5% hydrofluoric acid solution for about 5 minutes; coat a layer of plastic glue on the unpolished surface of the silicon wafer, and then deposit a layer of plastic glue on the silicon wafer by electroless deposition method. Layer of nano-silver particle film, the electroplating solution is 4.8M HF and 0.005M AgNO 3 Mix the solution for 1.5min; wash the silver-plated silicon chip with deionized water, and place it in 4.8M HF and 0.4M H 2 o 2 In the mixed solution, react at a constant temperature of 50°C for 60 minutes; put the corroded silicon chip into the acetone solution until the plastic glue on the back of the silicon chip falls off; finally use HNO 3 solution, HF solution and deionized water are washed and dried to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com