Method of running diaphragm pump, diaphragm pump and use of diaphragm pump

A diaphragm type, pipeline system technology, applied in the field of diaphragm type pump, can solve the problems of natural frequency change, inaccurate natural frequency, less effective pump effect, etc., to achieve the effect of increasing resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

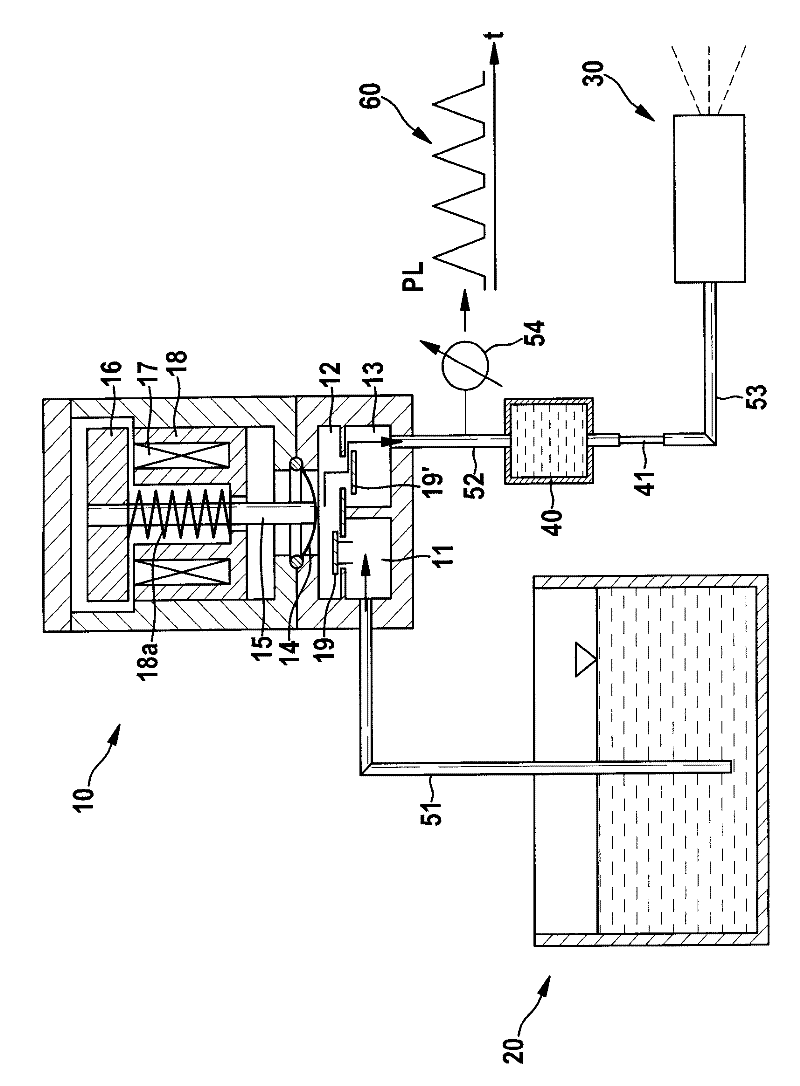

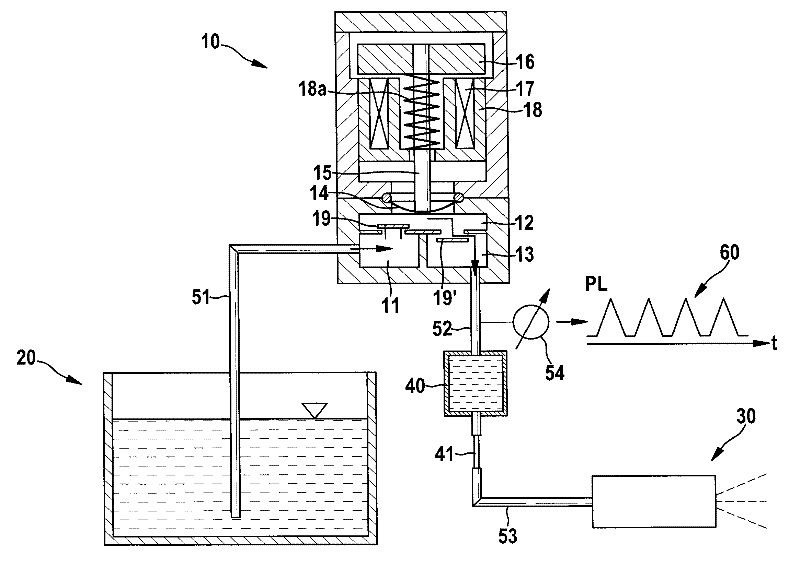

[0021] The drawing shows an electromagnetic diaphragm pump 10 used as a supply pump or metering pump for an SCR exhaust gas purification system. The diaphragm pump 10 conveys the water-soluble urea solution from the tank 20 to the metering device 30 . The dosing device 30 includes, for example, a solenoid injection valve, with which a water-soluble urea solution is injected as required into an exhaust line (not shown). The liquid medium is conveyed from the reducing agent tank 20 into the suction region 11 of the diaphragm pump 10 via the suction line 51 . The medium passes through the first non-return valve 19 into the diaphragm working chamber 12 and through the second non-return valve 19 ′ into the delivery region 13 of the diaphragm pump 10 . The liquid is delivered via the membrane 14 moved by the delivery piston 15 . The delivery piston 15 is connected to an armature 16 which is forced to move by means of a magnetic field generated by a ring coil 17 inside a lifting ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com