Method for preparing fluffy superfine fibers

An ultra-fine fiber and fluffy technology, which is applied in the field of preparation of fluffy ultra-fine fibers, can solve the problems of high local fiber content, inability to distribute uniformly, and reduced thermal insulation performance, and achieves short production cycle, improved thermal insulation effect, and convenience. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the electrospinning method is single-needle electrospinning, and the receiver used is a cuboid receiver without a cover. The electrode connection method is to connect the high-voltage positive pole to the receiver, and the negative pole to the spinneret.

[0023] The cover cuboid receiver of this embodiment is made like this:

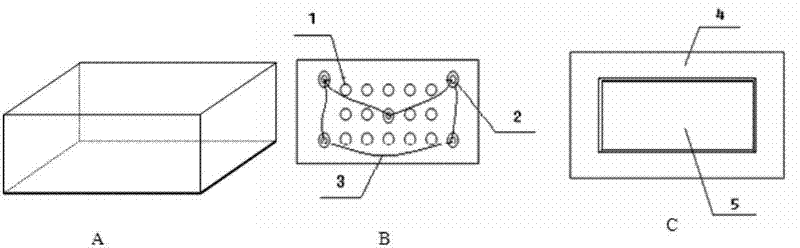

[0024] refer to figure 1 : a non-conductive rectangular parallelepiped (a) is made from a hard paper shell; a conductive sheet 5 is pasted on its bottom 4, and the conductive sheet is an iron sheet; 10 to 100 small holes 1 are chiseled at the bottom of the iron sheet, and the diameter of the hole is 0.1~10mm; select 5 of the holes to place the conductor 2 with the tip, the tip conductor is an iron nail, and the arrangement of the holes is as follows figure 1 (b). Wire 3 is used to connect between the tip conductor and the conductive sheet.

[0025] The steps of the specific process are as follows:

[0026] (1) Pretreatmen...

Embodiment 2

[0035] refer to figure 2 and image 3 :

[0036] In this example, multi-needle electrospinning is adopted, and the receiver used is a multi-column receiver. The electrode connection method is to connect the high-voltage positive pole to the spinneret, and the negative pole to the receiver.

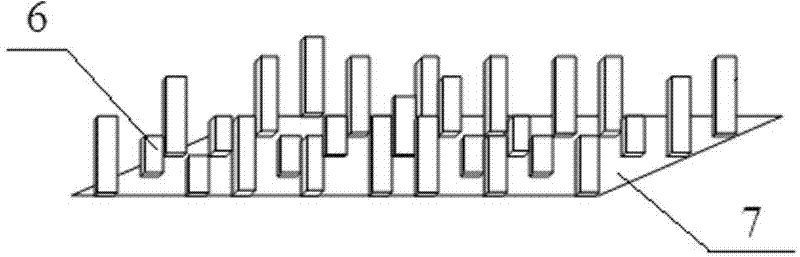

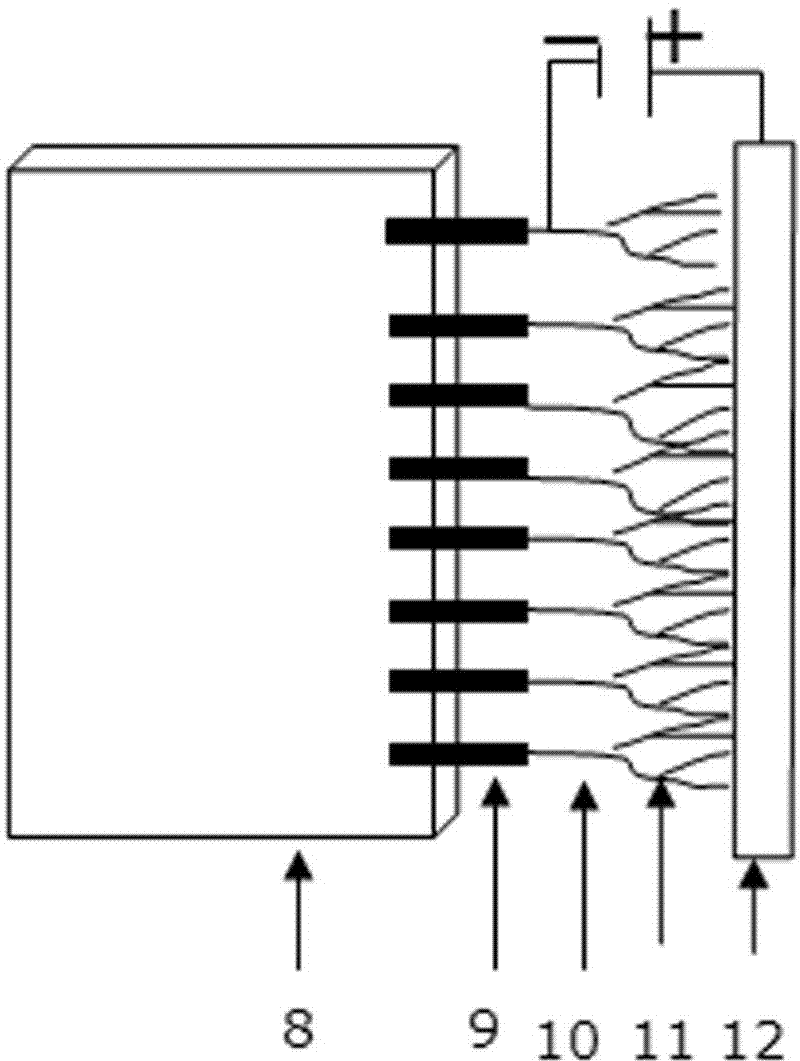

[0037] In the multi-column receiver, 20 to 50 rectangular parallelepiped columns 6 of 1 to 15 cm in length and length, which are cut from polyurethane foam, are fixed in disorder on aluminum foil 7 of 68×58 cm, and then the aluminum foil is fixed on the multi-needle electrospinning On the rotating cylinder 12 of the wire machine. During electrospinning, the syringe 9 filled with the spinning solution is fixed on the insulating plate 8, the spinning solution is sprayed out from the needle 10, and a jet 11 is formed under the action of a high-voltage electric field force, and finally, the prepared fibrils are collected in a multi-column shape. on the receiver.

[0038] The step of conc...

Embodiment 3

[0043] In this embodiment, single-needle electrospinning is adopted, and the cuboid receiver with the cover removed is used for collection. The electrode connection mode is the same as that in Example 1.

[0044] The cuboid without the cover is made of a conductor, and no conductive sheet is pasted on the bottom of the cuboid.

[0045] The conductor is a barbed wire net with a diameter of 0.1-0.3mm; the mesh is square with a side length of 2mm.

[0046] The specific experimental procedure is the same as that in Example 1, except that during electrospinning, the inner diameter of the needle used is 1.5 mm, and the voltage used is 25 kV; during air pre-oxidation, the heating rate is 5° C. / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com