Belt sludge treatment press filter

A sludge treatment and filter technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high moisture content, large floor area, and bulky sludge, and achieve low sludge water content and sewage The effect of reducing the moisture content of mud and reducing its volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

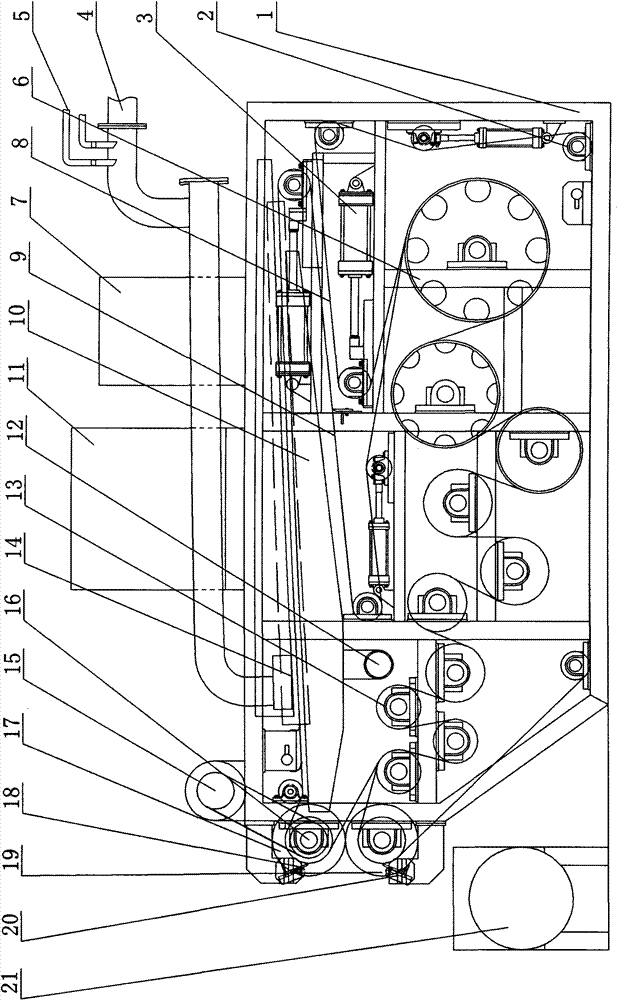

[0011] The present invention comprises a frame 1, an electric control box 11 and a pneumatic control box 7 are arranged on the frame 1, a sludge delivery pipe 4 having a drug inlet 5 is arranged above the frame 1, and upper and lower A pair of identical gears 16, the gears 16 are driven by a motor 15, and the shafts of the pair of gears 16 are respectively provided with an upper squeeze roller 17 and a lower squeeze roller 19; the upper filter belt 9 on the upper squeeze roller 17 passes through the The output port 14 of the sludge transport pipe 4 bypasses the pre-press roller 6 and the press roller 13, and returns to the upper press roller 17; the lower filter belt 8 on the lower press roller 19 bypasses the middle roller 2, 6 overlap with the upper filter belt 9, and then return to the lower squeeze roller 19 after passing through the squeeze roller 13; a water receiving tank 10 is arranged below the upper filter belt 9 below the output port 14, and a drain pipe 12 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com