Temperature field testing system for exhaust plume of engine analogue combustion device and testing method thereof

A combustion device and testing system technology, which is applied in the testing of engines, testing of machinery/structural components, thermometers using electrical/magnetic components that are directly sensitive to heat, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

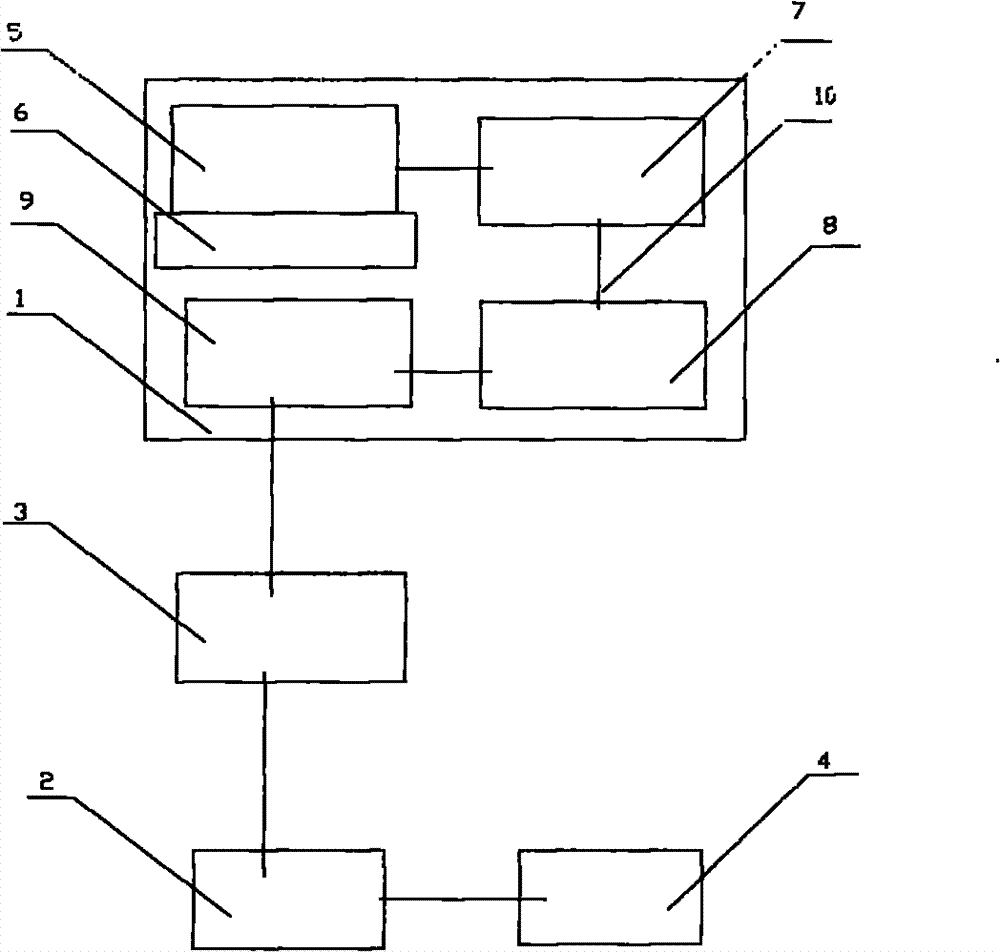

[0035] A temperature field test system for an engine simulating combustion device jet tail flame, which includes: a combustion device data acquisition system 1, a fuel consumption device control system 2, and a data processing system 3, and the combustion device data acquisition system 1 passes electrical signals or data The signal is connected to the data processing system 3, the fuel consumption device control system 2 is connected to the data processing system 3 through electrical signals or data signals, and the fuel consumption device control system 2 is connected to the engine simulation combustion device 4 through electrical signals or data signals.

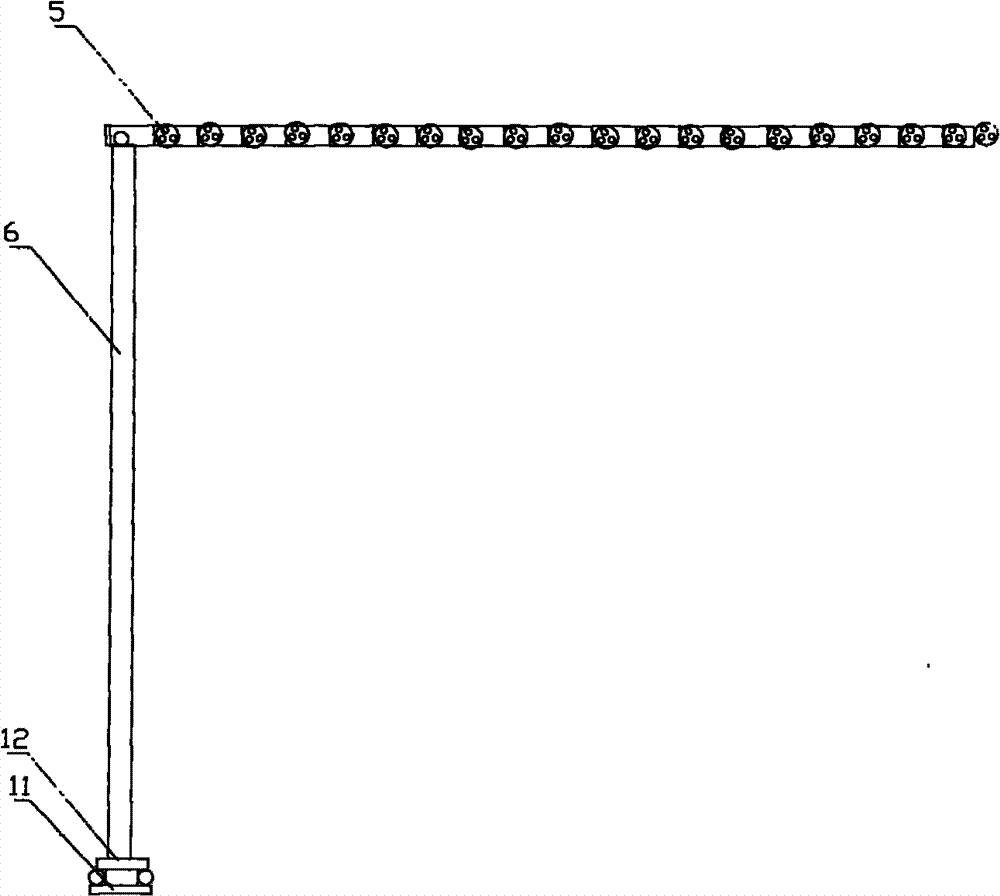

[0036] The combustion device data acquisition system 1 includes: a thermocouple group 5, a thermocouple fixed support 6, a temperature transmitter 7, a signal conversion module 8, and a combustion device data acquisition card 9; the thermocouple group 5 is erected on the thermocouple fixed support 6 and connected to the tem...

Embodiment 2

[0043]Comprising a track 11 and a mobile control system, the mobile control system includes a mobile control module and a mobile controller 12, the mobile controller 12 is arranged on the track 11, is connected with the mobile control module by electrical signals, and the thermocouple fixing bracket is fixed on On the mobile controller, during the measurement process, the mobile control module can send electrical signals to control the movement of the mobile controller, and the mobile controller drives the thermocouple fixed bracket to move, so that the thermocouple probe can be moved flexibly and accurately to obtain different positions in different areas The data. The thermocouple set includes 3 thermocouple probes. All the other are with embodiment 1.

Embodiment 3

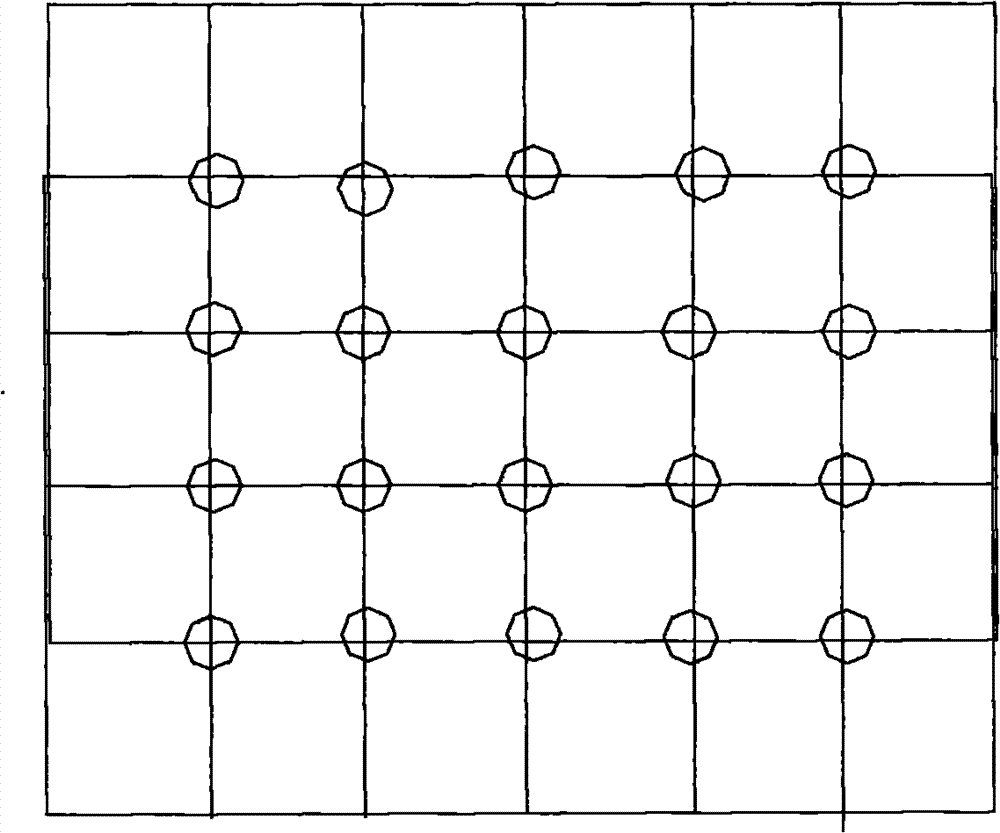

[0045] Select the test state and test range; for a simulated flame-throwing device, select a working state as a stable working state, such as the selected fuel type is RP-3 jet fuel, and the fuel flow rate for combustion and fuel supply is 6.0g / s, the air supply flow rate is 0.60kg / s, and the average temperature of the nozzle is 780K. In this working state, use a method to measure and describe the temperature distribution in the three-dimensional space formed by the rotation of the center line of the nozzle in the direction of the flamethrower, with the center line of the nozzle as the axis of symmetry and the radius of 30cm. . In the tests, the length of this axis was 180 cm. During the test, the length of this axis is taken as 180cm, and the temperature in the space of a cylinder formed by rotating around this axis with a radius of 30cm is taken as the research object. As the common sense of scientific and technical personnel can know, the temperature field change of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com