Construction method for reinforcing concrete structure by using carbon fibers

A concrete structure and carbon fiber reinforcement technology, which is applied in building maintenance, building structure, construction, etc., can solve the problems of complicated construction and large space occupation, and achieve simple and rapid construction, small space occupation, creep and small thermal expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A construction method for strengthening concrete structures using carbon fibers, comprising the following sequential steps:

[0049] (1) Concrete base treatment

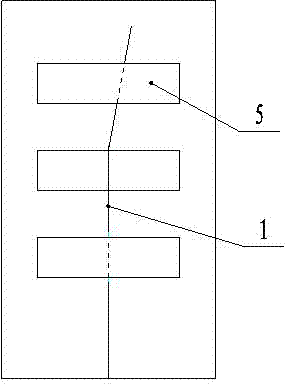

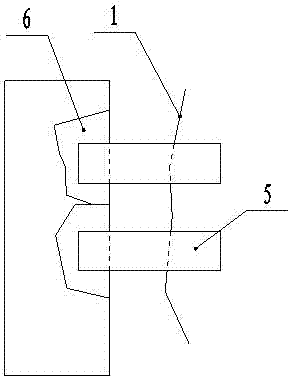

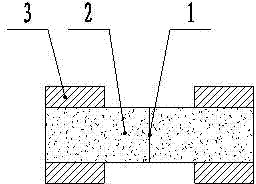

[0050] Before the construction of carbon fiber reinforcement, part of the load should be removed as much as possible to minimize the load on the structure or components during carbon fiber pasting construction, and then if figure 1 As shown, the protective mortar 3 around the crack 1 is removed, and the surface of the concrete member 2 is smoothed with a grinder at the position where the carbon fiber sheet 5 is to be pasted, and the crack 1 with a width of less than 0.2 mm is coated and sealed with epoxy resin. , the crack 1 with a width between 0.2-1mm is filled with epoxy resin, and the crack 1 with a width greater than 1mm is treated with pressure potting. During the potting process, such as figure 2 As shown, a V-shaped groove 4 with a width of 20 mm and a depth of 10 mm should be chiseled at the crack 1...

Embodiment 2

[0072] Compared with the first embodiment above, the only difference is that the crack 1 is at the foot of the wall. In the step (4.3), before the undercoating step, as Figure 4 As shown, the hole 6 should be dug at the foot of the wall in advance. The depth of the hole 6 should make the carbon fiber cloth around the crack reach 400mm symmetrically, and the distance between two adjacent carbon fiber sheets along the direction of the crack should be 100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com