Binary ordered colloidal crystal template and preparation method and use thereof

A technology of colloidal crystal templates and colloidal crystals, which is applied in crystal growth, chemical instruments and methods, and single crystal growth, can solve the problems of large average particle distance, unfavorable applications, and inability to produce binary colloidal crystals. Scientific method and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The concrete steps of preparation are:

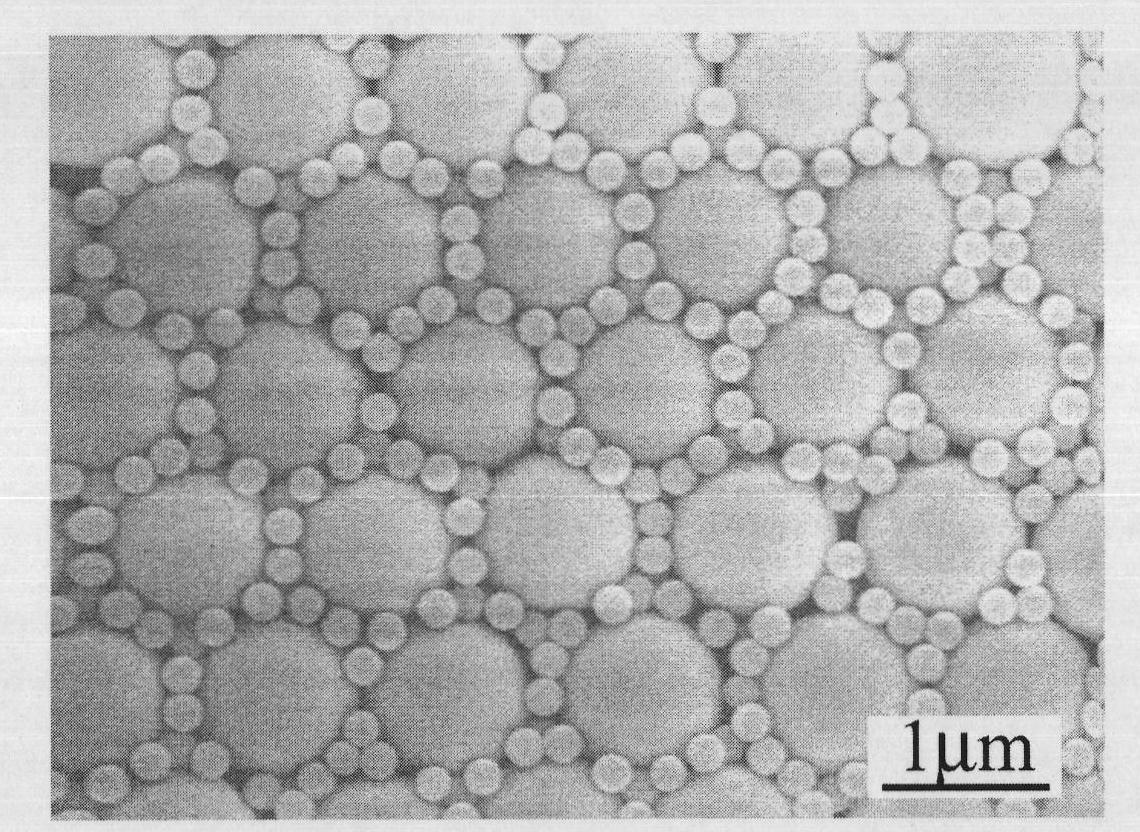

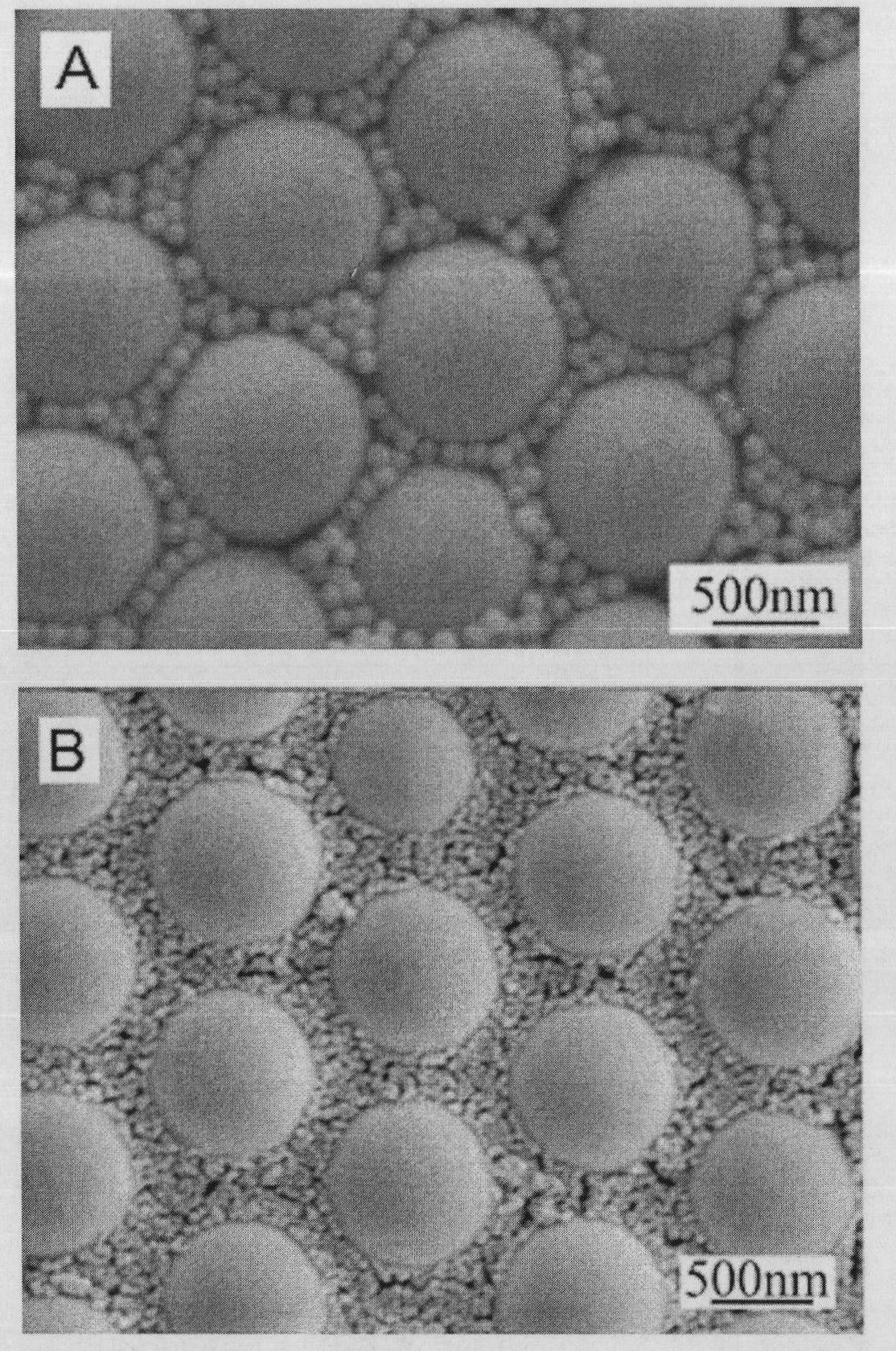

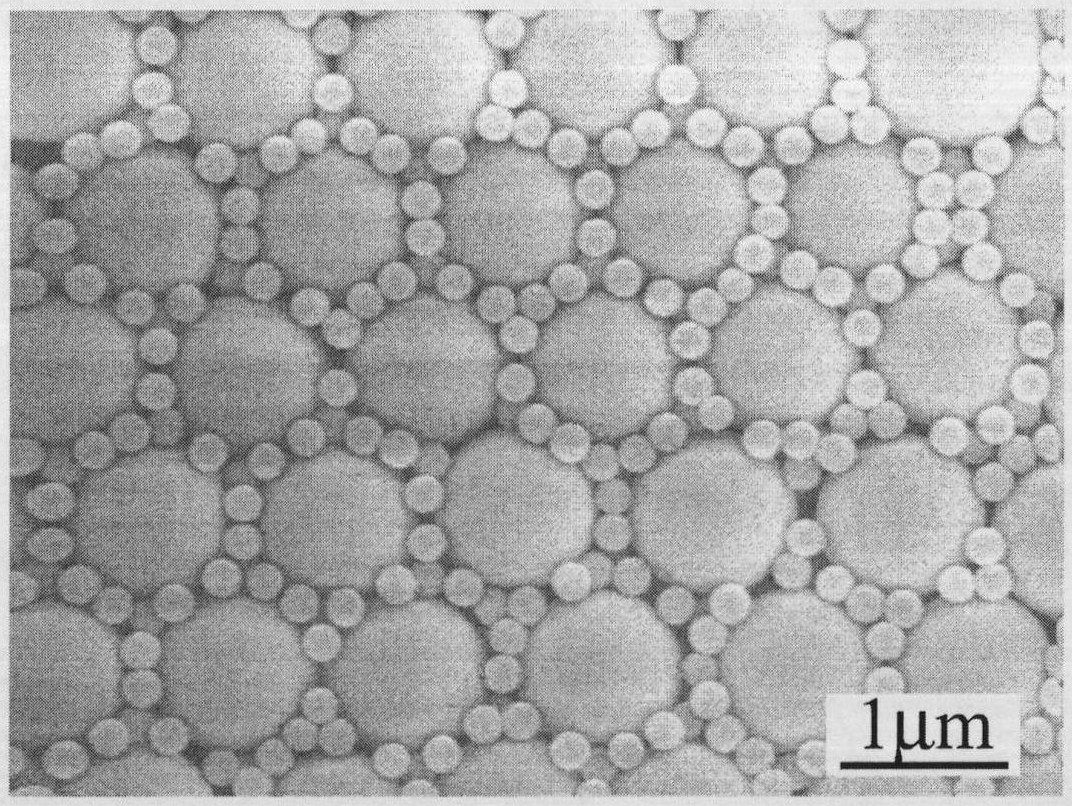

[0026] First, the large-diameter polystyrene colloidal sphere solution and the small-diameter polystyrene colloidal sphere solution with a mass percentage solubility of 1.5% are uniformly mixed according to a volume ratio of 10:1 to obtain a mixed solution; wherein, the large-diameter polystyrene The colloid ball diameter of the ethylene colloid sphere solution is 1000nm, and the colloid sphere diameter of the small-diameter polystyrene colloid sphere solution is 250nm. Then, the mixed liquid was added dropwise on the substrate and then spin-coated and shaken off; wherein, the substrate was glass, the volume of the mixed liquid dropped onto the substrate was 4 μL, and the spin-coating speed was 300 r / s when the mixed liquid was thrown off. After natural drying at a temperature of 24°C, a product similar to figure 1 , figure 2 A and figure 2 The binary ordered colloidal crystal template shown in B.

Embodiment 2

[0028] The concrete steps of preparation are:

[0029] First, the large-diameter polystyrene colloidal sphere solution and the small-diameter polystyrene colloidal sphere solution with a mass percentage solubility of 3% are uniformly mixed according to a volume ratio of 15:1 to obtain a mixed solution; wherein, the large-diameter polystyrene The colloidal sphere diameter of the ethylene colloidal sphere solution is 1000nm, and the colloidal sphere diameter of the small-diameter polystyrene colloidal sphere solution is 200nm. The mixed liquid was added dropwise on the substrate and then spin-coated and shaken off; wherein, the substrate was glass, the volume of the mixed liquid dropped onto the substrate was 5.5 μL, and the spin-coated spin-off was 500 r / s. After natural drying at a temperature of 25°C, the following figure 1 shown, approximately figure 2 A and figure 2 The binary ordered colloidal crystal template shown in B.

Embodiment 3

[0031] The concrete steps of preparation are:

[0032] First, the large-diameter polystyrene colloidal sphere solution and the small-diameter polystyrene colloidal sphere solution with a mass percentage solubility of 5% are uniformly mixed according to a volume ratio of 20:1 to obtain a mixed solution; wherein, the large-diameter polystyrene The colloid ball diameter of the ethylene colloid sphere solution is 1000nm, and the colloid sphere diameter of the small-diameter polystyrene colloid sphere solution is 150nm. Then, the mixed liquid was added dropwise on the substrate and then spin-coated and shaken off; wherein, the substrate was glass, the volume of the mixed liquid dropped onto the substrate was 7 μL, and the spin-coated spin-off was 700 r / s. After natural drying at a temperature of 26°C, a product similar to figure 1 , figure 2 A and figure 2 The binary ordered colloidal crystal template shown in B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com