Equipment for filling granulated hole saw semi-finished product in oil removing boiler

A technology for filling equipment and semi-finished products, which is used in lifting devices, cleaning hollow objects, crowbars, etc., can solve problems such as harmful workers' health, waste of energy, materials and labor, saving raw materials, reducing harm to the human body, and reducing The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

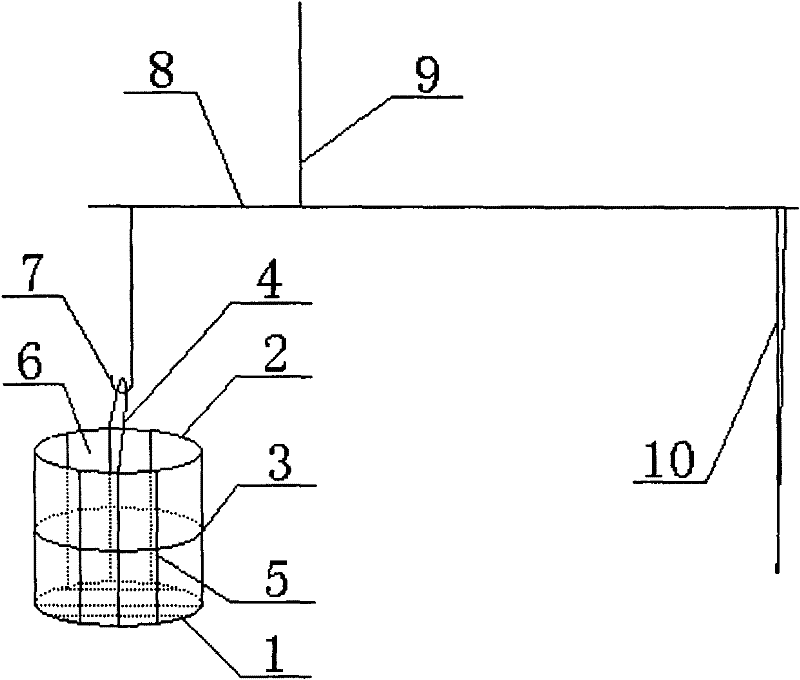

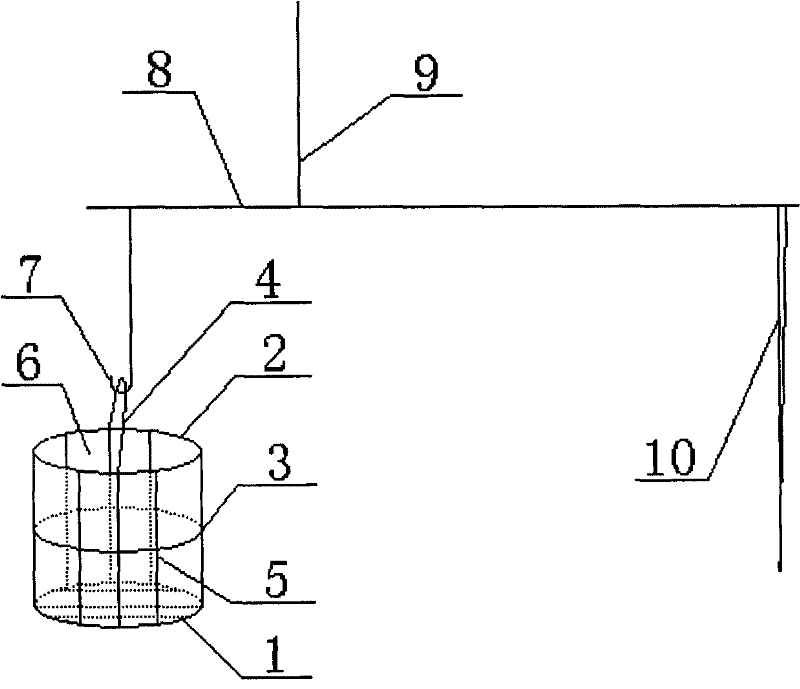

[0009] Such as figure 1 Shown, the filling equipment in the grit hole saw semi-finished product degreasing pan of the present invention, it comprises suspension rail, suspension hook (7), lever (8), fulcrum suspension rope (9) and power arm drooping rope (10). The shape of the hanging rail should be consistent with the shape of the oil removal pan. The bottom ring (1) and upper ring (2) of the hanging rail are made of round steel with a diameter of 10 mm, and the middle ring (3) is made of round steel with a diameter of 6-8 mm. Make, hurdle handle (4) extends bottom ring with diameter 10 millimeters of round steel, and the station post (5) of hurdle is made with diameter 6-8 millimeter round steel, and hurdle bottom circle also connects three 8 millimeters of diameter round steel hurdles, and the hurdle bottom (6) Use aluminum nets to attach from the inside. The aluminum nets at the bottom of the fence and the bottom of the fence are fixed with iron wires. There must be a dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com