Process for preparing Cinacalcet hydrochloride tablets or capsules

A kind of technology of cinacalcet hydrochloride and capsule, applied in the field of preparation of pharmaceutical preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

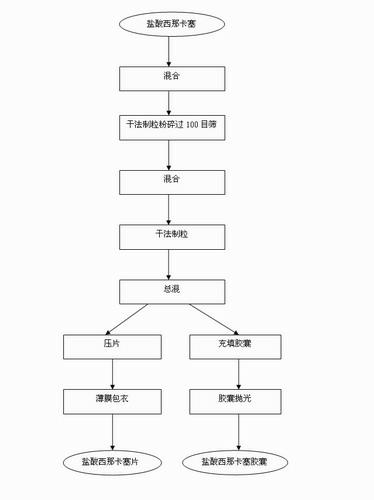

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Cinacalcet Hydrochloride 30mg, 60mg, 90mg Sustained Release Tablets

[0026] prescription

quantity

content%

33mg

18.33%

6000

15mg

8.33%

20mg

11.11%

70mg

38.89%

Crospovidone

13mg

7.22%

partially pregelatinized starch

27mg

15.00%

2mg

1.12%

Total

180g

100%

[0027] 1) Cinacalcet hydrochloride was crushed through a 100-mesh sieve, and mannitol, microcrystalline cellulose, crospovidone, and partially pregelatinized starch were passed through a 60-mesh sieve.

[0028] 2) Add to the mixer and mix for 15 minutes,

[0029] 3) Dry granulation in the dry granulator, and the granules pass through a 20-mesh sieve.

[0030] 4) Mix the granules of operation 3) with magnesium stearate evenly.

[0031] 5 tablets

[0032] 30mg 180mg / tablet 100 tablets

[0033...

Embodiment 2

[0046] Preparation of Cinacalcet Hydrochloride 30mg, 60mg, 90mg Sustained Release Tablets

[0047] prescription

quantity

content%

Cinacalcet hydrochloride

33mg

16.50%

polyethylene glycol 6000

15mg

7.50%

25mg

12.50%

75mg

37.50%

Crospovidone

18mg

9.00%

partially pregelatinized starch

32mg

16.00%

2mg

1.00%

Total

200mg

100%

[0048] 1) Cinacalcet hydrochloride was crushed through a 100-mesh sieve, and mannitol, microcrystalline cellulose, crospovidone, and partially pregelatinized starch were passed through a 60-mesh sieve.

[0049] 2) Add to the mixer and mix for 15 minutes,

[0050] 3) Dry granulation in the dry granulator, and the granules pass through a 20-mesh sieve.

[0051] 4) Mix the granules of operation 3) with magnesium stearate evenly.

[0052] 5 tablets

[0053] 30mg 200mg / tabl...

Embodiment 3

[0067] Preparation of Cinacalcet Hydrochloride 30mg, 60mg, 90mg Sustained Release Tablets

[0068] prescription

quantity

content%

Cinacalcet hydrochloride

33mg

15.00%

polyethylene glycol 6000

15mg

6.82%

30mg

13.64%

80mg

36.36%

Crospovidone

23mg

10.45%

partially pregelatinized starch

37mg

16.82%

Magnesium stearate

2mg

0.91%

Total

220mg

100%

[0069] 1) Cinacalcet hydrochloride was crushed through a 100-mesh sieve, and mannitol, microcrystalline cellulose, crospovidone, and partially pregelatinized starch were passed through a 60-mesh sieve.

[0070] 2) Add to the mixer and mix for 15 minutes,

[0071] 3) Dry granulation in the dry granulator, and the granules pass through a 20-mesh sieve.

[0072] 4) Mix the granules of operation 3) with magnesium stearate evenly.

[0073] 5 tablets

[0074] 30mg 220mg / tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com