Turbine

A turbine and cam technology, applied in the direction of engines, mechanical equipment, engine components, etc., can solve the problems of limited service life, short service life of power conversion units, etc., and achieve the effect of simple design and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

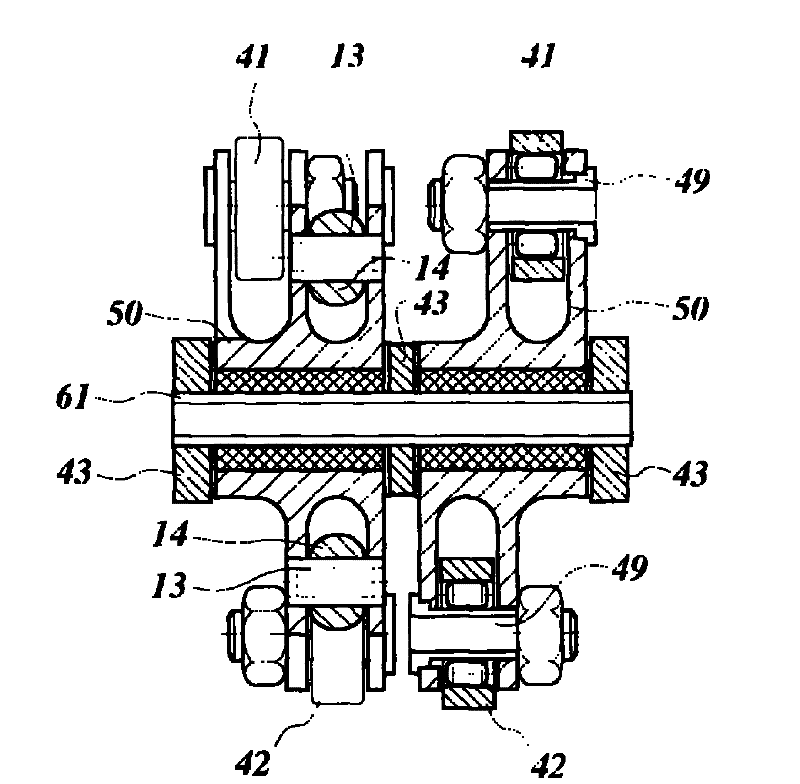

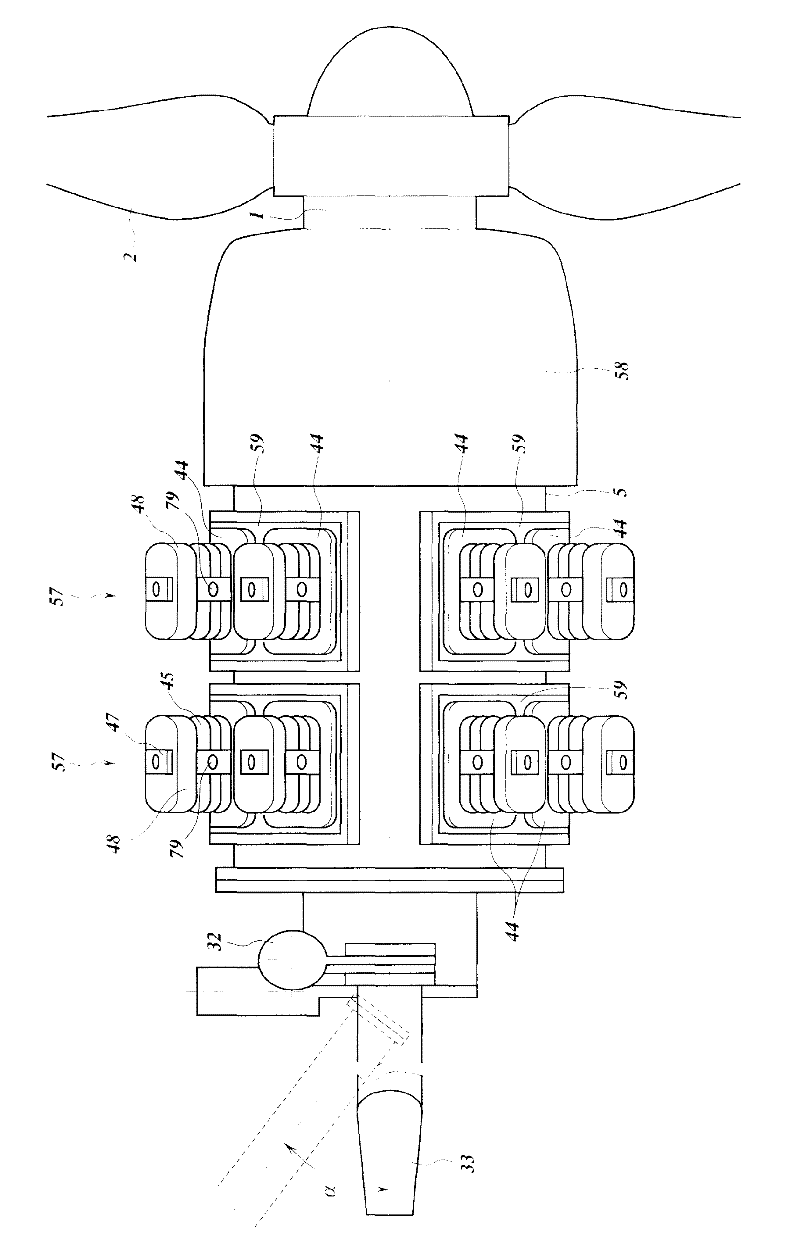

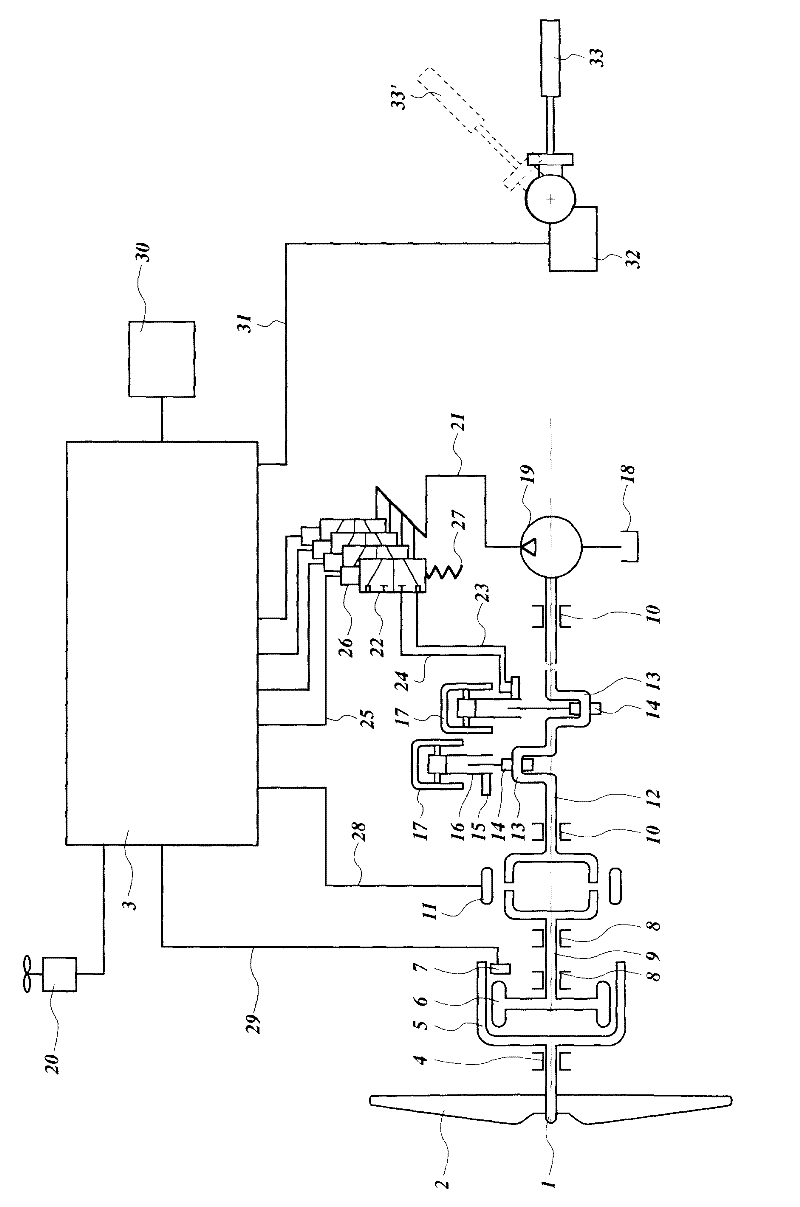

[0033] figure 1 A functional block diagram of a wind turbine with turbine blades 2 coupled to a turbine shaft 1 rotating in a bearing 4 of the turbine shaft is shown. A turbine shaft 1 of a wind turbine has an outer coupling half 5 which rotates an inner coupling half 6 mounted to a coupling shaft 9 which rotates in a bearing 8 of the coupling shaft. A switchable coupling 11 couples the coupling shaft 9 to the compressor shaft 12 . The compressor shaft 12 rotates in compressor shaft bearings 10 and drives a pump 19 , and has a crank pin 13 coupled to an inner connecting rod 14 . Each inner connecting rod 14 has a connecting rod coupling 15 for coupling the inner connecting rod 14 to an outer connecting rod 16 . The outer connecting rod 16 is fastened to a piston 17 which is reciprocally movable within the cylinder and thus compresses the refrigerant.

[0034] The control system 3 is designed to control the settings of the refrigerant compressor. The control system 3 is cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com