P-type ZnO and n-type GaN combined ZnO-based light-emitting devices and manufacturing methods thereof

A light-emitting device, p-type technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of short light-emitting wavelength, achieve the effect of overcoming the narrow band gap and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

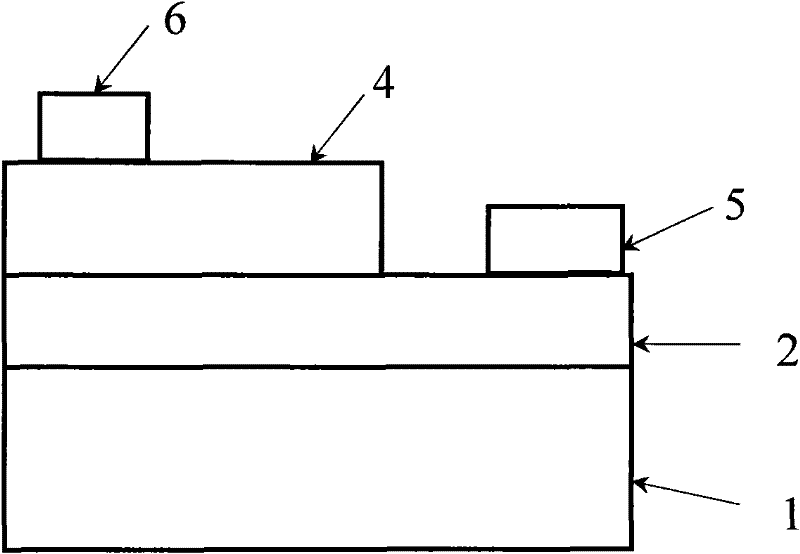

[0024] ZnO-based light-emitting devices combining p-type ZnO and n-type GaN without a current lower confinement layer. The structure of this ZnO-based light-emitting device combined with p-type ZnO and n-type GaN without a current lower confinement layer is shown in the appendix figure 2 , characterized in that the GaN epitaxial layer 2 is an n-type GaN thin film material, no current lower confinement layer 3 is prepared, the ZnO light-emitting layer 4 is a p-type ZnO-based thin film material, and a p-type ZnO-based material is directly prepared on the n-type GaN epitaxial layer 2 to emit light Layer 4.

[0025] Its preparation process is, with Al 2 o 3 substrate as an example, using the current mature conventional MOCVD process on Al 2 o 3 The substrate grows an n-type (such as Si-doped) GaN epitaxial layer 2 of 1 to 10 microns, and the carrier concentration is 10 18 ~10 20 / cm 3 , and then adopt the MOCVD method, especially the special ZnO film growth MOCVD equipment...

Embodiment 2

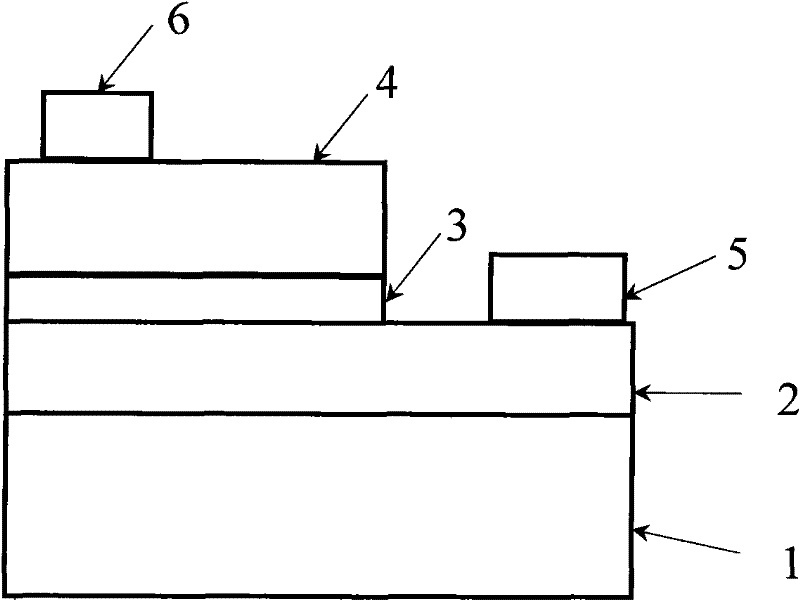

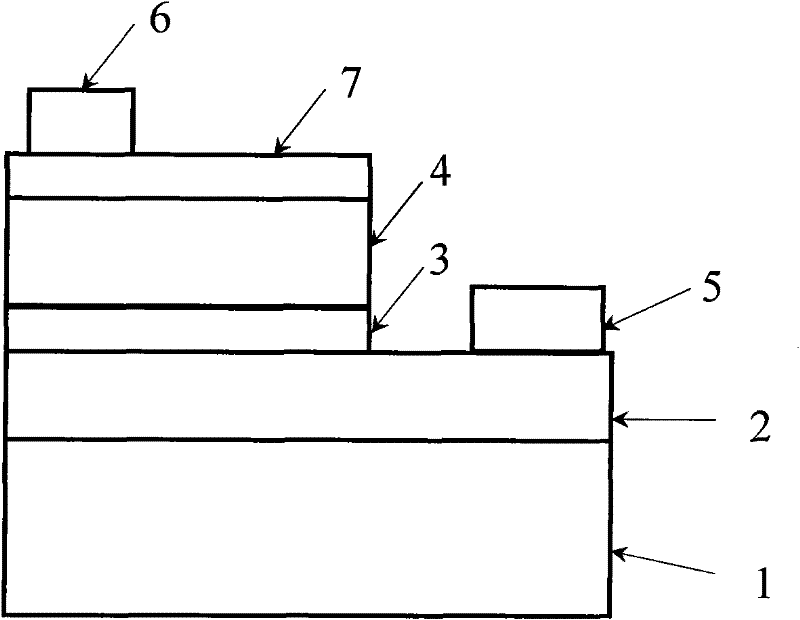

[0027] A ZnO-based light-emitting device based on the combination of p-type ZnO and n-type GaN under the current confinement layer of AlGaN thin film material. The ZnO-based light-emitting device structure of the combination of p-type ZnO and n-type GaN under the current confinement layer of this AlGaN thin film material is shown in the appendix figure 1 , the structure and preparation process of the GaN epitaxial layer 2 and the ZnO light-emitting layer 4 are the same as in Example 1, which is characterized in that a layer of current limiting layer 3 is grown on the GaN epitaxial layer 2, and the current limiting layer 3 of this layer is n Type Alx Ga 1-x N material thin film, wherein the value of x is in the range of 0.01 to 0.5; the preparation process is as follows: Al 2 o 3 substrate as an example, using the current mature conventional MOCVD process method on Al 2 o 3 The substrate grows an n-type GaN epitaxial layer 2 including a buffer layer of 1 to 10 microns, and ...

Embodiment 3

[0029] Ga 2 o 3 ZnO-based light-emitting devices combining p-type ZnO and n-type GaN under the current confinement layer of thin film materials. This Ga 2 o 3 See the attached figure 1 , the structure and preparation process of the GaN epitaxial layer 2 and the ZnO light-emitting layer 4 are the same as in Example 1, and it is characterized in that a layer of Ga is prepared on the GaN epitaxial layer 2 2 o 3 Material thin film current lower confinement layer 3; its preparation process except Ga 2 o 3 Except for the different manufacturing process of the current lower confinement layer 3 of the material thin film, the rest of the process is the same as that of Embodiment 2; devices with this structure can also use n-type SiC single crystal substrates.

[0030] Ga 2 o 3 There are two methods for preparing the material thin film current confinement layer 3:

[0031] One is prepared by MOCVD method. The Ga source can be trimethylgallium (TMGa) or triethylgallium (TEGa). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com