Artificial musical instrument sounding membrane

A musical instrument and man-made technology, applied in the field of musical instrument sounding membranes, can solve the problems of sound quality, unstable timbre, noise or muffled sound, mildew, etc., and achieve the effect of wide source of raw materials, long service life and natural timbre

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

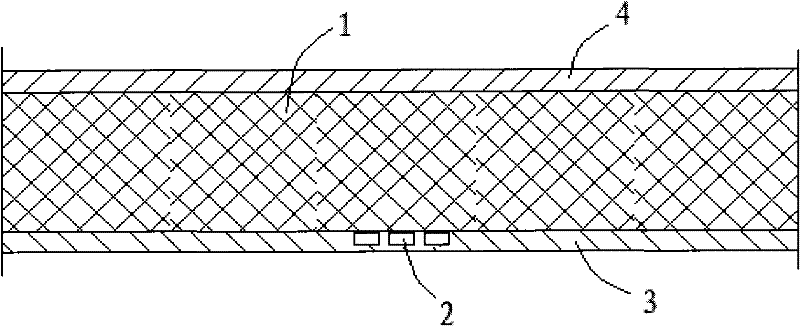

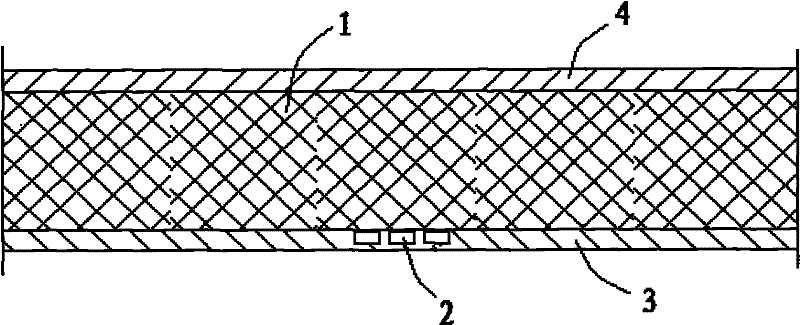

[0018] Use a piece of polyester cloth with a thickness of 1mm as the base weaving layer 1, and use two chemical raw material fibers or animal fur fibers or plant fibers with a diameter of about 0.8mm as the acoustic wires 2 and attach them laterally to the inner side of the base weaving layer 1. , place the polyphonic wire 2 so that the sound wave conduction diffused to the surroundings has "directionality", and then apply a bond coat 3 of cyanoacrylate polymer adhesive or epoxy resin glue, bond coat 3 It can be completely covered on the base braiding layer 1 or the sound-focusing wire 2 ; it can also be partially covered on the base braiding layer 1 or the sound-focusing wire 2 . The outer side of the base weaving layer 1 is covered with a layer of simulated snakeskin or python scales or a pattern layer 4 printed with a layer of simulated snakeskin or python scales, forming a base weaving layer 1, sound-focusing wire 2, bonding coating Layer 3 and pattern layer 4 are combined...

Embodiment 2

[0020] Use a piece of polyester cloth with a thickness of 0.8mm as the base weaving layer 1, and attach three chemical raw material fibers or animal fur fibers or plant fiber sound-focusing threads 2 with a diameter of about 0.6mm to the inner side of the base weaving layer 1 in a longitudinal direction. , place the sound-focusing wire 2 so that the sound wave conduction diffused to the surroundings has "directionality" and then coat a bonding coating 3 of a layer of cyanoacrylate polymer adhesive or epoxy resin glue, the bonding coating 3 can be completely It is covered on the base weaving layer 1 or the sound-focusing wire 2 ; it can also be partially covered on the base weaving layer 1 or the sound-focusing wire 2 . The outer side of the base weaving layer 1 is covered with a layer of simulated snakeskin or python scales or a pattern layer 4 printed with a layer of simulated snakeskin or python scales, forming a base weaving layer 1, sound-focusing wire 2, bonding The coati...

Embodiment 3

[0022] A piece of polyester cloth with a thickness of 0.6mm is used as the base weaving layer 1, and 5 chemical raw material fibers or animal fur fibers or plant fiber acoustic threads 2 with a diameter of about 0.5mm are attached to the inner side of the base weaving layer 1 in irregular directions. Place the sound-focusing wire 2 so that the sound wave conduction diffused to the surroundings has "directionality" and then coat a layer of cyanoacrylate polymer adhesive or epoxy glue with a bonding coating 3, the bonding coating 3 can be It is completely covered on the base weaving layer 1 or the sound-focusing wire 2 ; it can also be partially covered on the base weaving layer 1 or the sound-focusing wire 2 . The outer side of the base weaving layer 1 is covered with a layer of simulated snakeskin or python scales or a pattern layer 4 printed with a layer of simulated snakeskin or python scales, forming a base weaving layer 1, sound-focusing wire 2, bonding The coating 3 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com