Dynamic preventative maintenance method for electromechanical equipment

A technology of preventive maintenance and electromechanical equipment, applied in the direction of electrical digital data processing, instruments, calculations, etc., can solve problems such as failure to achieve the purpose of preventive maintenance, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

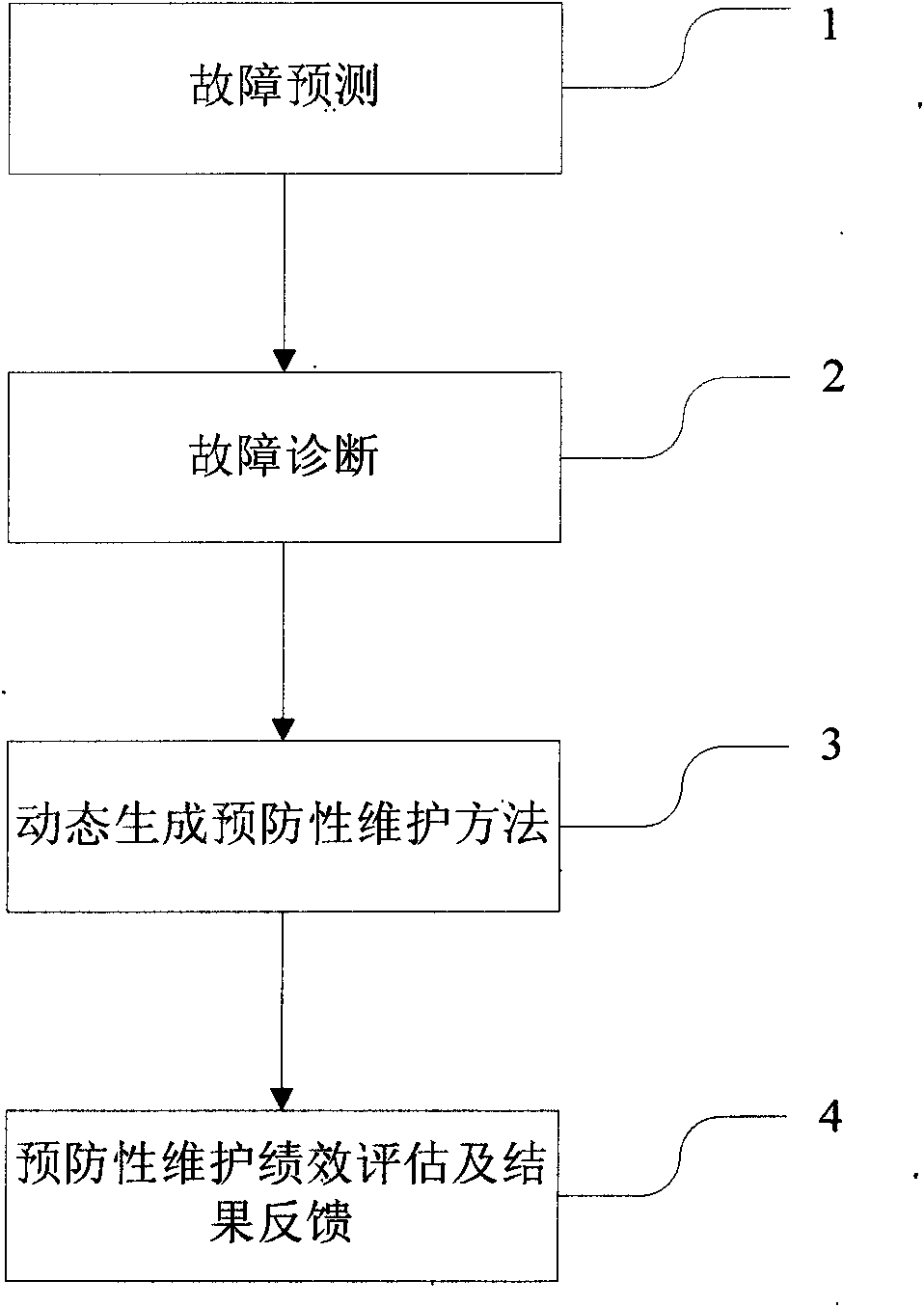

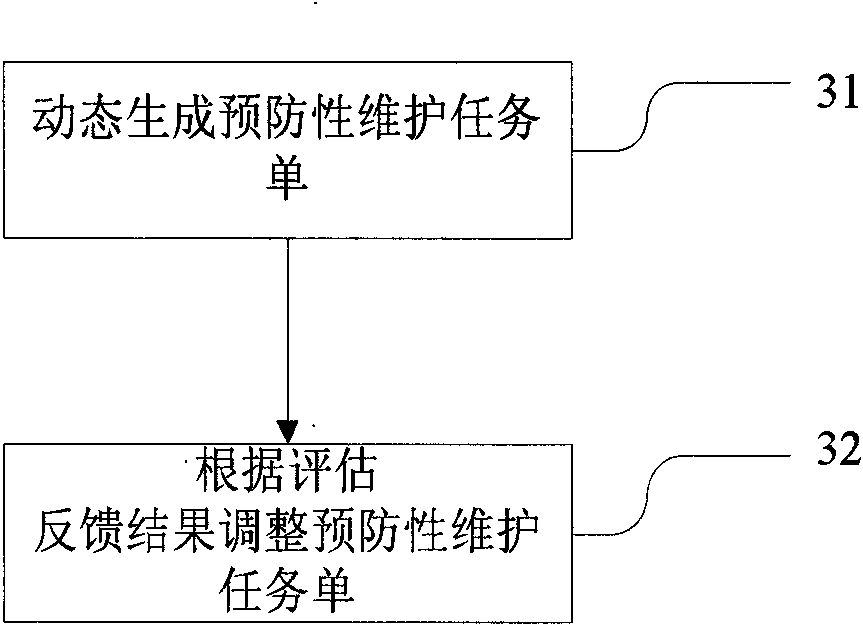

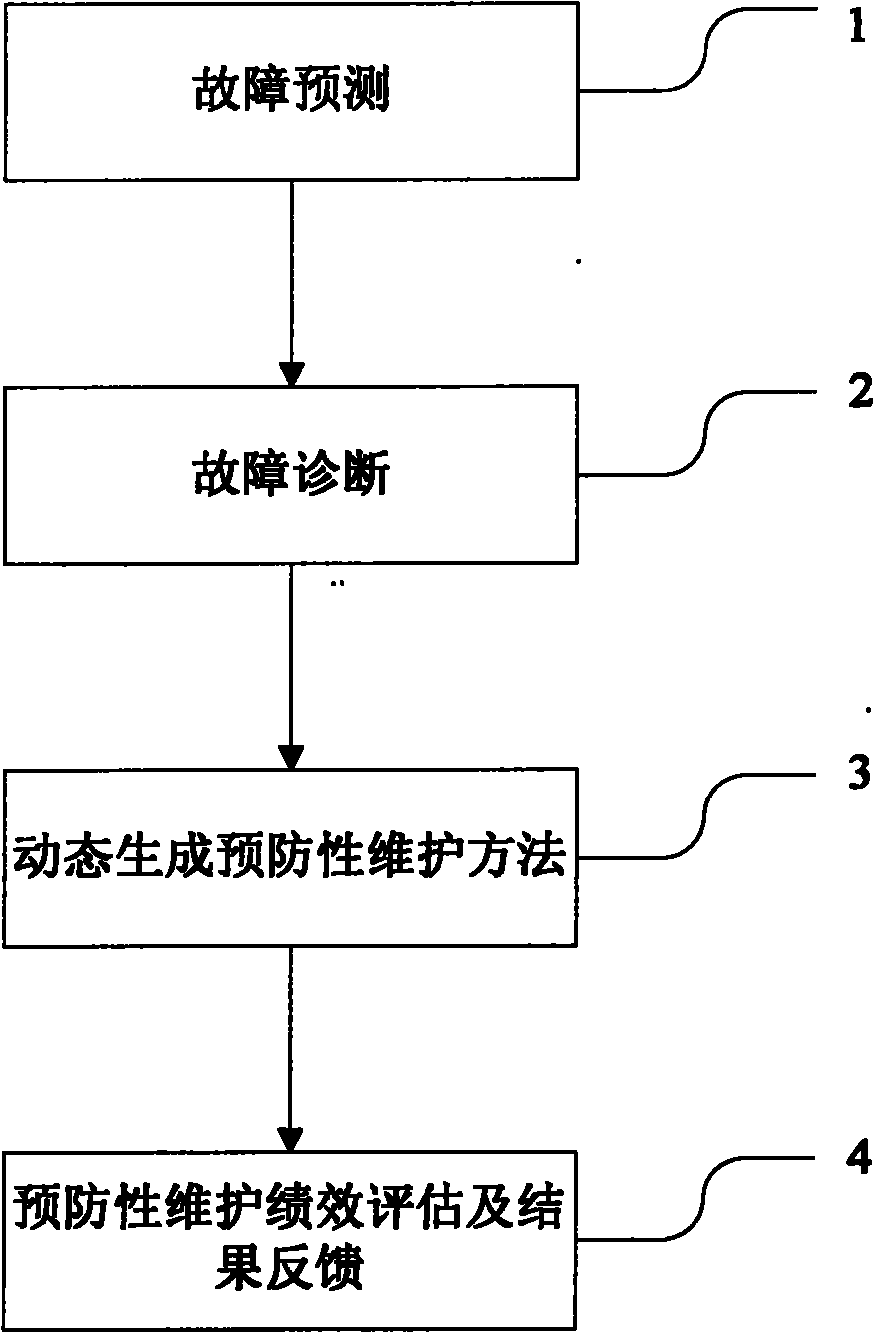

[0015] Please refer to figure 1 The dynamic preventive maintenance method for electromechanical equipment includes fault prediction, such as step 1; fault diagnosis, such as step 2; dynamic generation of preventive maintenance methods, such as step 3; preventive maintenance performance evaluation and result feedback, such as step 4.

[0016] Fault prediction, as in step 1. The fault prediction method is selected to predict the possible fault time and fault type of electromechanical equipment.

[0017] Fault prediction mainly includes: (1) Predicting the time of failure of electromechanical equipment, where the time can be a small interval and does not require a specific time. (2) Predict the types of mechanical and electrical equipment failures. Because different electromechanical equipment has different fault distribution rules in its entire life cycle, it is necessary to analyze the historical fault records of electromechanical equipment first to obtain the possible fault ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com