Touch panel roll and manufacturing method thereof

A technology for a touch panel and a manufacturing method, which is applied in the fields of instruments, electrical digital data processing, and input/output processes of data processing, etc., can solve the problem that transparent films and glass substrates consume a lot of manpower and time costs, reduce the pass rate, touch The panel production process steps are complicated and other problems, to achieve the effect of shortening the production process time, reducing waste, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

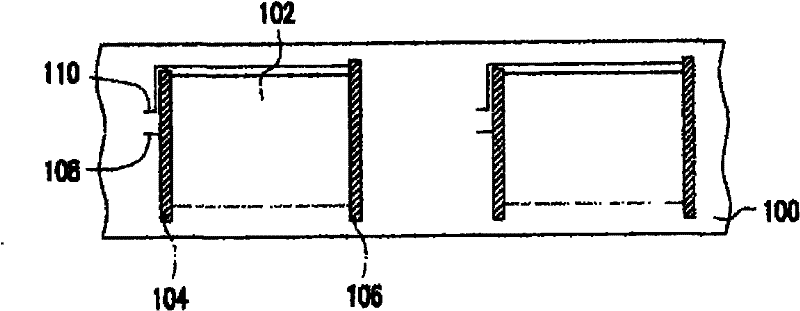

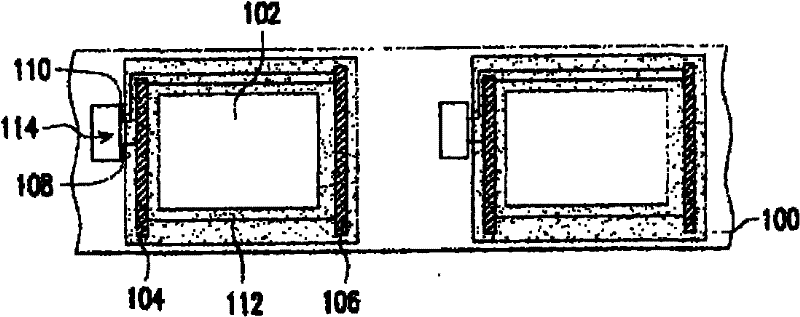

[0036] Figure 1A to Figure 1B It is a top view of the manufacturing process of the first structure volume according to the embodiment of the present invention. In this embodiment, the first structure volume can be regarded as the upper structure in the touch panel. First, please refer to Figure 1A , forming a transparent conductive layer 102 on the flexible substrate 100 . The material of the flexible substrate 100 is, for example, polyethylene terephthalate or polycarbonate. The material of the transparent conductive layer 102 is, for example, a transparent conductive oxide (such as indium tin oxide), an organic transparent conductive substance (such as poly(3,4-dioxylthiophene): sulfonated polystyrene), or carbon nanotubes. The method for forming the transparent conductive layer 102 is, for example, to firstly form a transparent conductive material layer on the flexible substrate 100 . Then, the roll of photoresist material is bonded to the flexible substrate 100 in a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com