Pressure container corrosion fatigue testing device with closed-loop control

A pressure vessel and corrosion fatigue technology, which is applied in the field of fatigue test equipment, can solve the problems of lack of strain measurement and leakage monitoring, inability to test pressure vessels or pipelines, and inability to conduct corrosion fatigue tests, etc., to achieve high-precision automatic closed-loop control, avoid Effects of corrosion, reduction of manufacturing cost and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

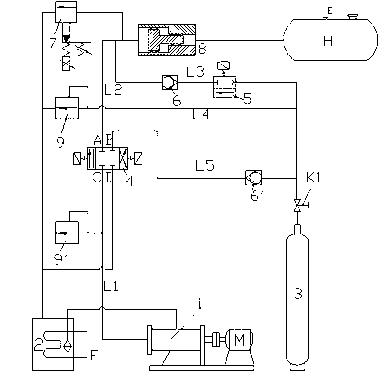

[0017] Such as figure 1 As shown, the pressure vessel corrosion fatigue test device includes a high-pressure pump station 1, an oil tank 2, an accumulator 3, an overflow valve, an electromagnetic proportional overflow valve 7, a one-way valve, a corrosive medium isolation booster cylinder 8, and a resistance strain gauge E . The inlet of the high-pressure pump station 1 is connected to the fuel tank 2, and the outlet pipeline L1 is divided into two routes: one is connected to the inlet C of the three-position four-way valve 4, and the other is connected to the fuel tank 2 through the first overflow valve 9'; the three-position The other inlet D of the four-way valve 4 is connected to the oil tank 2, one outlet A is connected to the corrosive medium isolation booster cylinder 8, and the other outlet B is connected to the accumulator 3 through the first one-way valve 6'; the accumulator The outlet of 3 is divided into two ways: one way is connected to the oil tank 2 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com