Vertical internal and external mixing shaft-seal-free self-sucking pump

A shaft-sealless, self-priming pump technology, applied in the direction of non-variable pumps, pumps, drive pumps, etc., can solve the problems of reducing the self-priming capacity of self-priming pumps, small external mixing area, and increasing the impeller water absorption resistance, etc., to achieve The effect of speeding up the gas-water separation speed, increasing the external mixing area, and speeding up the exhaust speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

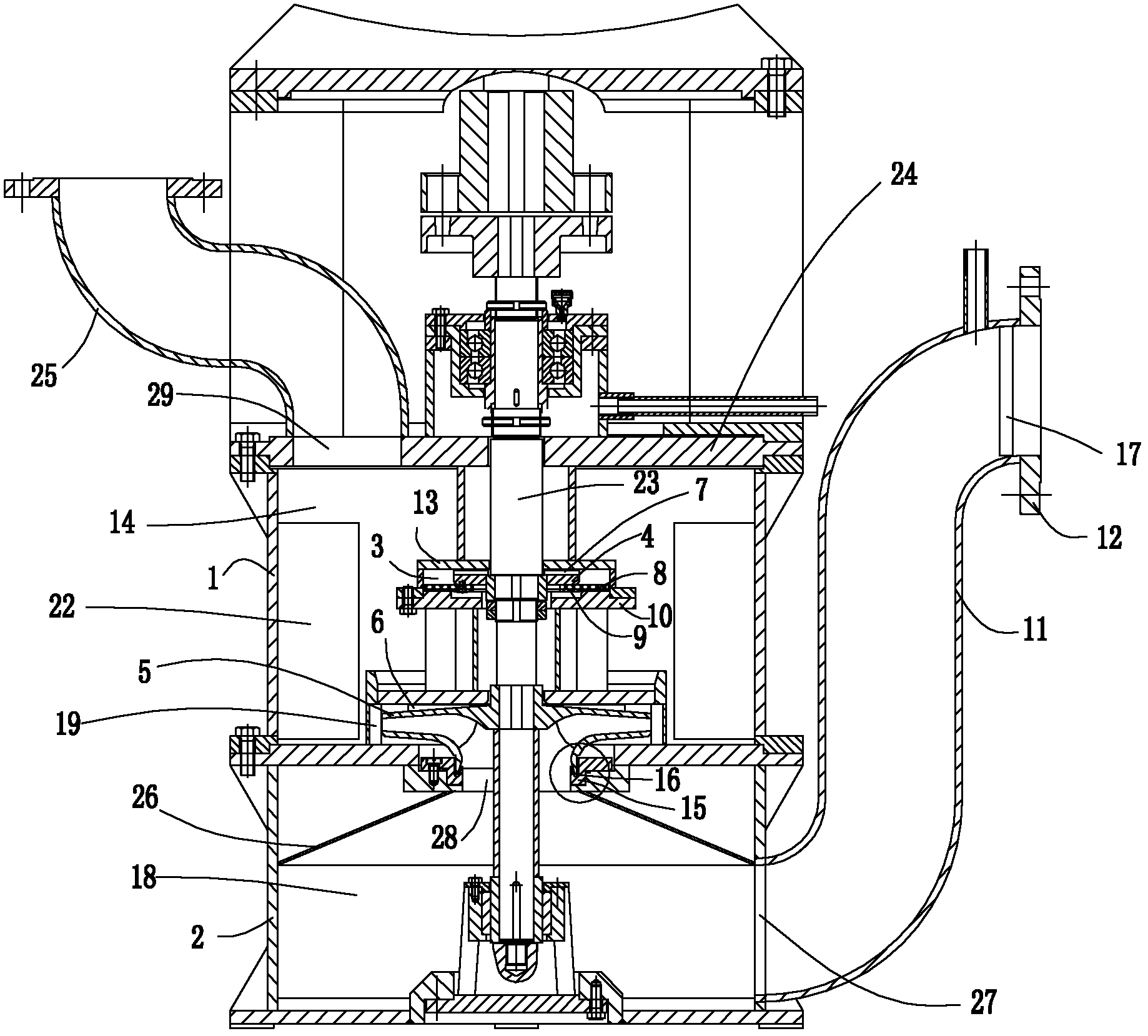

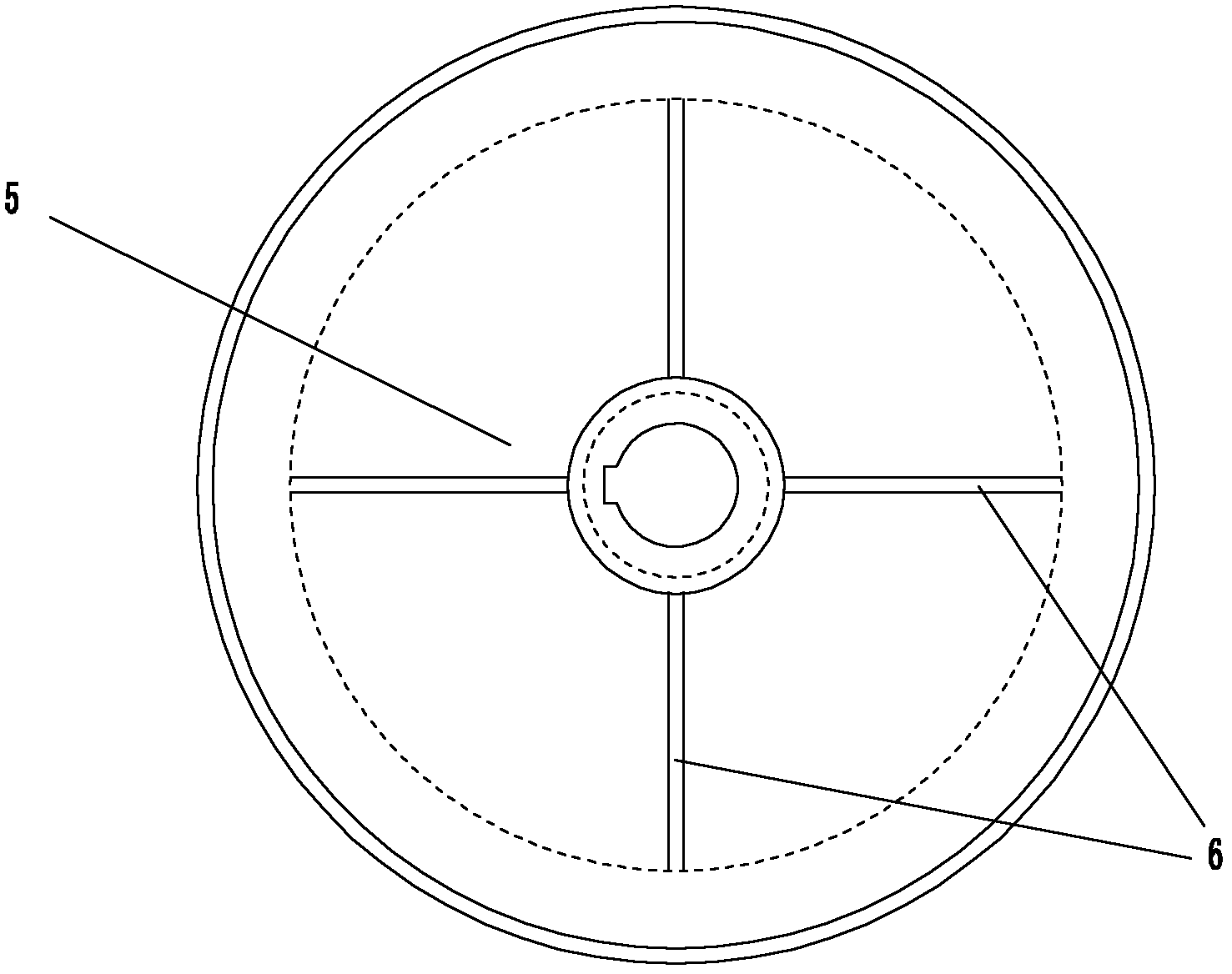

[0041] Such as figure 1Shown is a vertical self-priming pump with internal and external mixing without shaft seal according to an embodiment of the present invention, which includes a pump body composed of an upper pump casing 1 and a lower pump casing 2, a pump cover 24 is placed above the pump body, and a water suction pump is arranged in the pump body. Chamber 18, vortex chamber 19, air-water separation chamber 14 and auxiliary impeller chamber 3, the water suction chamber has a water inlet pipe 11, and the inlet of the water inlet pipe is provided with a water inlet pipe flange 12 for connecting external pipelines for water supply, and the top of the water suction chamber is provided with There is a water outlet 28 of the water suction chamber (that is, the suction port of the main impeller), and the vortex chamber is located in the air-water separation chamber. The vortex chamber is equipped with the main impeller 5, and is sealed with 6 rings of the main impeller seal. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com