Rinsing method and device of potassium fluotantalate product obtained through sodium reduction

A technology of potassium fluorotantalate and its products is applied in the field of washing and reclaiming tantalum powder, which can solve the problems of poor fluidity, loss of surface area, and small pores inside the particles, and achieve the effects of good fluidity, low leakage current and good porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

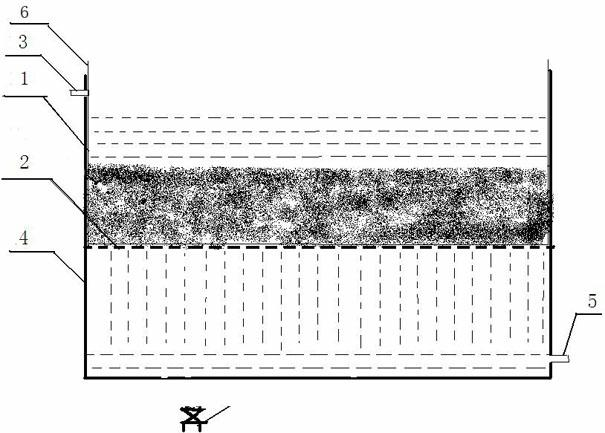

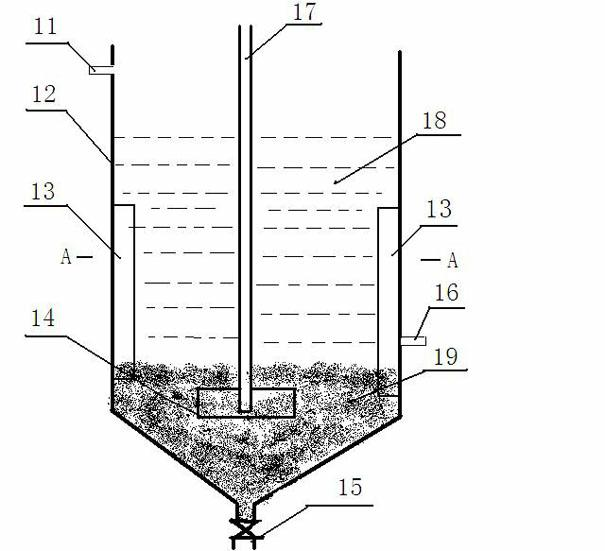

[0037] The above-mentioned sodium reduction product broken particle S1 is put into such as figure 1 In the filter cloth bag of the filter washing tank shown, the material is flattened, the thickness of the material is about 15cm, and cold deionized water at 25°C is passed through the water inlet pipe to submerge the material and let the water flow by itself. Use pH test paper Test the pH value of the tantalum particles into the water to be 14, which is strongly alkaline; measure the temperature in the tantalum powder at 28°C; start raking once every 1 hour, after 1 hour, the temperature of the material is the same as that of the water, and after 3 hours, stir together 3 times, and then use pH test paper to test the pH value of the water in the washing tank to 7, which is already neutral. Use hot deionized water at about 80°C to continue washing, rake once every 4 hours, and filter with hot water. After washing for 12 hours, the conductivity of the test water was 2 μS / cm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com