Method for producing ribonucleic acid by high-density fermentation high-nuclear Candida lipolytica

A high-density fermentation and ribonucleic acid technology, applied in the field of ribonucleic acid production, can solve problems such as high energy consumption, and achieve the effects of simplifying production procedures, reducing emissions, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

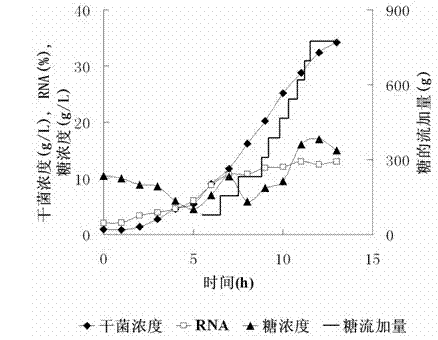

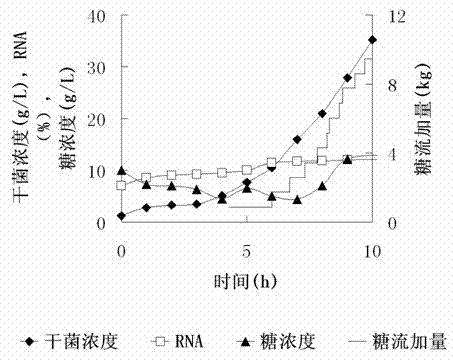

Embodiment 1

[0029] Medium composition

[0030] Slant medium: 30g / L glucose, 3g / L beef extract, 3g / L yeast extract, 5g / L ammonium sulfate, 0.1g / L anhydrous ferrous sulfate and 25g / L agar;

[0031] Shake flask medium: 35g / L molasses, 1.0g / L magnesium sulfate, 1.0g / L urea, 0.1g / L ammonium sulfate, 0.05g / L zinc sulfate, 0.05g / L ferrous sulfate, 0.05g / L of NaCl and 1ml / L of phosphoric acid

[0032] Batch medium: 10g / L molasses, 1.0g / L magnesium sulfate, 1.0g / L urea, 0.1g / L ammonium sulfate, 0.05g / L zinc sulfate, 0.05g / L ferrous sulfate, 0.05 g / L of NaCl and 1ml / L of phosphoric acid

[0033] Feed medium a: molasses of 250g / L;

[0034] Feed medium b: 250g / L molasses, 7g / L magnesium sulfate, 7g / L urea, 2g / L ammonium sulfate, 1g / L zinc sulfate, 1g / L ferrous sulfate, 0.5g / L NaCl and 10ml phosphoric acid;

[0035] High-density continuous fermentation medium: 70g / L molasses, 1.8g / L magnesium sulfate, 1.8 urea, 0.425g / L ammonium sulfate, 0.225g / L ferrous sulfate, 0.225g / L zinc sulfate, 0.075 High-...

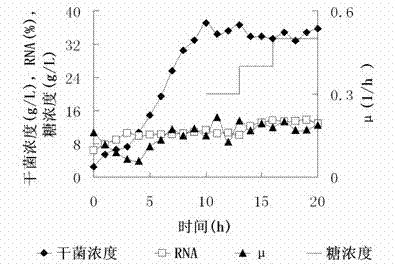

Embodiment 2

[0043] culture medium

[0044] Incline medium: 30g / L glucose, 3g / L beef extract, 3g / L yeast extract, 5g / L ammonium sulfate, 0.1g / L anhydrous ferrous sulfate and 25g / L agar

[0045] Shake flask medium: 45g / L molasses, 1.4g / L magnesium sulfate, 1.4g / L urea, 0.5g / L ammonium sulfate, 0.3g / L zinc sulfate, 0.3g / L ferrous sulfate, 0.2g / L of NaCl and 3ml / L of phosphoric acid

[0046] Feed medium a: molasses of 260g / L;

[0047] Feed medium b: 260g / L molasses, 8g / L magnesium sulfate, 8g / L urea, 3g / L ammonium sulfate, 2g / L zinc sulfate, 2g / L ferrous sulfate, 1g / L NaCl and 15ml phosphoric acid

[0048] Batch fermentation medium: 20g / L molasses, 1.4g / L magnesium sulfate, 1.4g / L urea, 0.5g / L ammonium sulfate, 0.3g / L zinc sulfate, 0.3g / L ferrous sulfate, 0.2g / L of NaCl and 3ml / L of phosphoric acid

[0049] Continuous high-density fermentation medium: 80g / L molasses, 2.4g / L magnesium sulfate, 2.4 urea, 0.625g / L ammonium sulfate, 0.312g / L ferrous sulfate, 0.312g / L zinc sulfate, 0.275 g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com