Bacillus amyloliquefaciens and method for producing chymosin by fermenting using same

A technology of Bacillus amyloliquefaciens and rennet, which is applied in Bacillus amyloliquefaciens strains, fermented to produce rennet, and the field of Bacillus amyloliquefaciens, which can solve problems such as gaps, achieve control of growth conditions, high enzyme production level, and easy growth conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

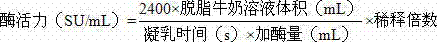

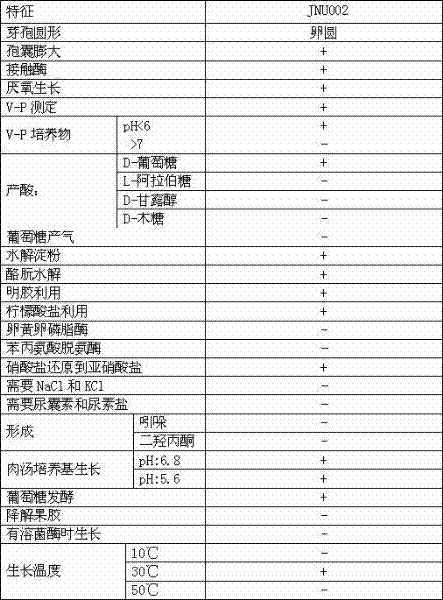

[0020] Example 1 Screening, isolation and identification of Bacillus amyloliquefaciens CCTCC NO: M 2011045

[0021] 1. Bacillus amyloliquefaciens JNU002 ( Bacillus amyloliquefacines JNU002) screening separation

[0022] Bacillus amyloliquefaciens JNU002 was isolated and screened from bran purchased from Sanliqiao Grain and Oil Market in Wuxi City. Get 6 grams of bran into a 250 milliliter sterilized Erlenmeyer flask containing 10 small glass beads, add 100 milliliters of sterile saline, vibrate and cultivate on a shaker at 150 rpm for 20 minutes, and let stand for 2 hours; Transfer 90 ml of the above mixture into a conical flask filled with 90 ml of nutrient broth medium (peptone 5g / L, glucose 5g / L, sodium chloride 5g / L), at 33°C and 150 rpm Cultivate for 12 hours; take the above culture solution and dilute it to 10 -6 、10 -7 、10 -8 Take 100 microliters of the diluted solution of each concentration and spread it on the milk medium plate (skim milk powder 25g / L, agar 16g...

Embodiment 2

[0036] Example 2 Production of chymosin by liquid fermentation of Bacillus amyloliquefaciens CCTCC NO: M 2011045

[0037] (1) Slant culture: Bacillus amyloliquefaciens CCTCC NO: M 2011045 was inoculated on the slant medium and cultured at 32°C for 24 hours. The slant medium used was (unit: g / L): glucose 20, yeast extract 10, agar strip 20, prepared with tap water, pH natural, sterilized at 115°C for 20 minutes.

[0038](2) Seed culture: Use an inoculation loop to take a loop of the grown bacteria on the slant and insert it into the seed medium, cultivate at 35°C for 12 hours, and the shaker rotates at 150 rpm. The seed medium used is (gram / liter): Bran 30, sodium chloride 5, magnesium sulfate heptahydrate 5, potassium dihydrogen phosphate 2, calcium carbonate 3, prepared with tap water, pH natural; each 250 ml triangular bottle 30ml of seed medium, sterilized at 121°C for 30 minutes.

[0039] (3) Liquid fermentation culture: the fermentation medium used is (unit is gram per ...

Embodiment 3

[0040] Example 3 Production of rennet by liquid fermentation of Bacillus amyloliquefaciens CCTCC NO: M 2011045

[0041] The cultured seeds were placed in a 500 ml Erlenmeyer flask, in which the fermentation medium was 50 ml, the inoculum size was 100 microliters, and cultured at 32° C. for 60 hours with a shaker rotating at 150 rpm. The fermentation medium used is (g / L): glucose 20, bran 10, sodium chloride 6, magnesium sulfate heptahydrate 4.5, potassium dihydrogen phosphate 1, calcium carbonate 3, prepared with tap water, pH natural, 121°C Sterilize for 30 min. Other conditions were the same as in Example 2. After the cultivation was completed, the chymosin enzyme activity of the fermentation liquid was 3560 SU / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com