Novel method for preparing zirconium tungstate powder

A production method, technology of zirconium tungstate, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of harsh process conditions, long synthesis time, cumbersome steps, etc., and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

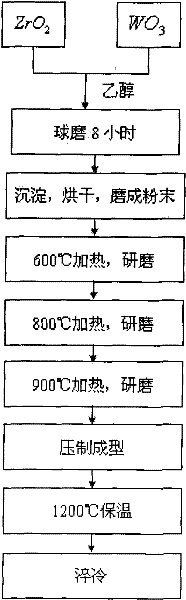

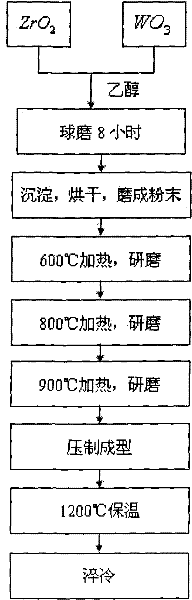

[0009] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

[0010] The process steps are: with ZrO 2 and WO 3 As raw material, according to ZrO 2 : WO 3 =1:2 stoichiometric ratio weighing. ZrO 2 and WO 3 Put it into a resin ball mill jar, add absolute ethanol as a solvent, and ball mill in a ball mill for 8 hours. Let it stand for precipitation, pour off the upper layer of clear solvent, dry it in an oven, take it out and grind it into powder. Put the powder in a quartz crucible, heat it at 600°C for 4 hours, take it out, put it in the air to cool down; grind it for 40 minutes; adjust the temperature to 800°C and heat it for 8 hours, take it out and grind it for 40 minutes after cooling in the furnace; then heat it at 900°C for 12 hours, and cool it in the furnace Finally, take it out and grind for 40min; put ZrO in a mold with a diameter of 60mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com