Active control closed-type hydrostatic guide rail

A static pressure guide rail and active control technology, applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc., can solve the problems of affecting the processing accuracy, high processing accuracy of capillary tubes and torsion plates, and easy fatigue damage of diaphragms, etc., to achieve Extensive adaptability, convenient maintenance, and the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

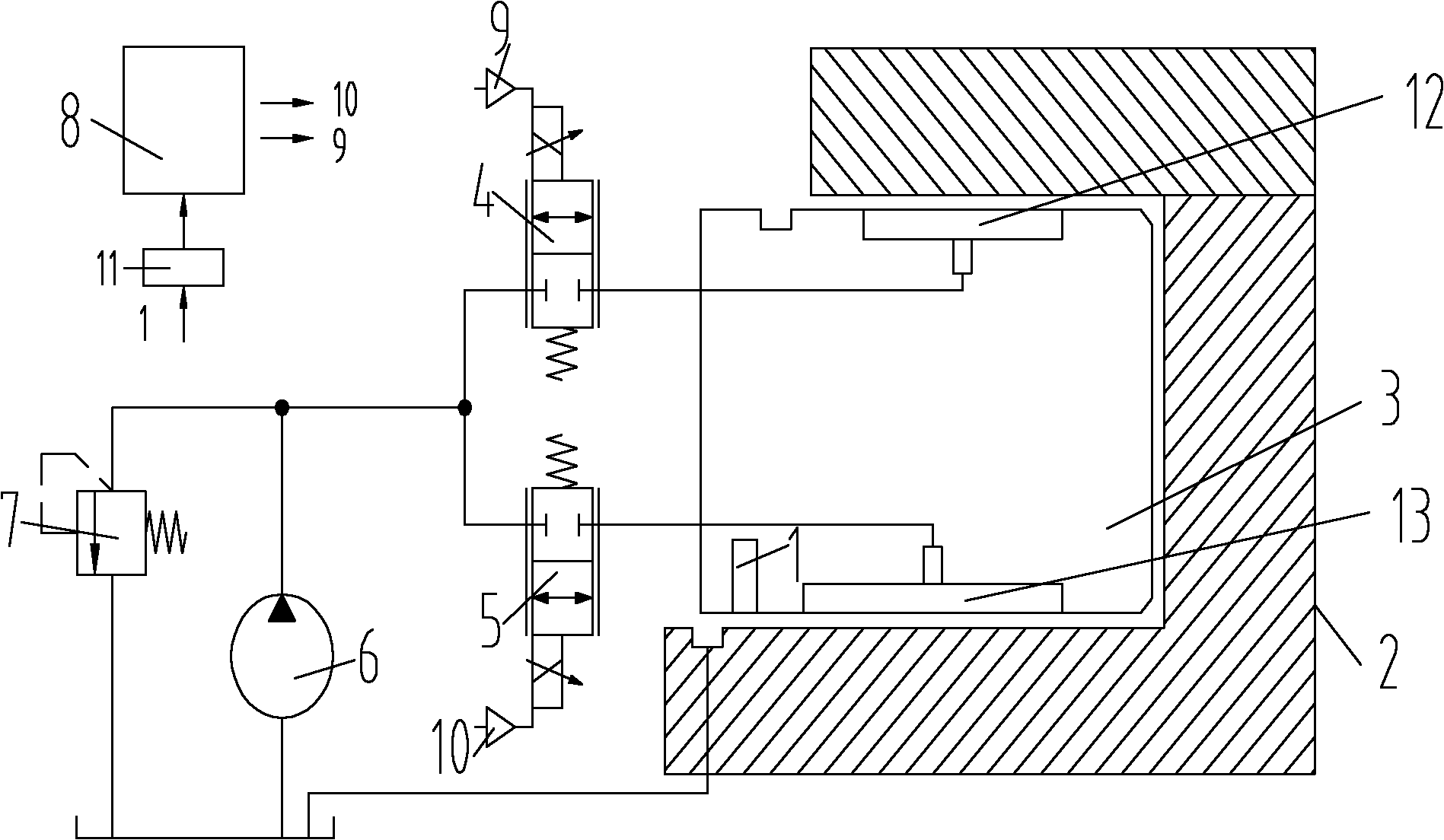

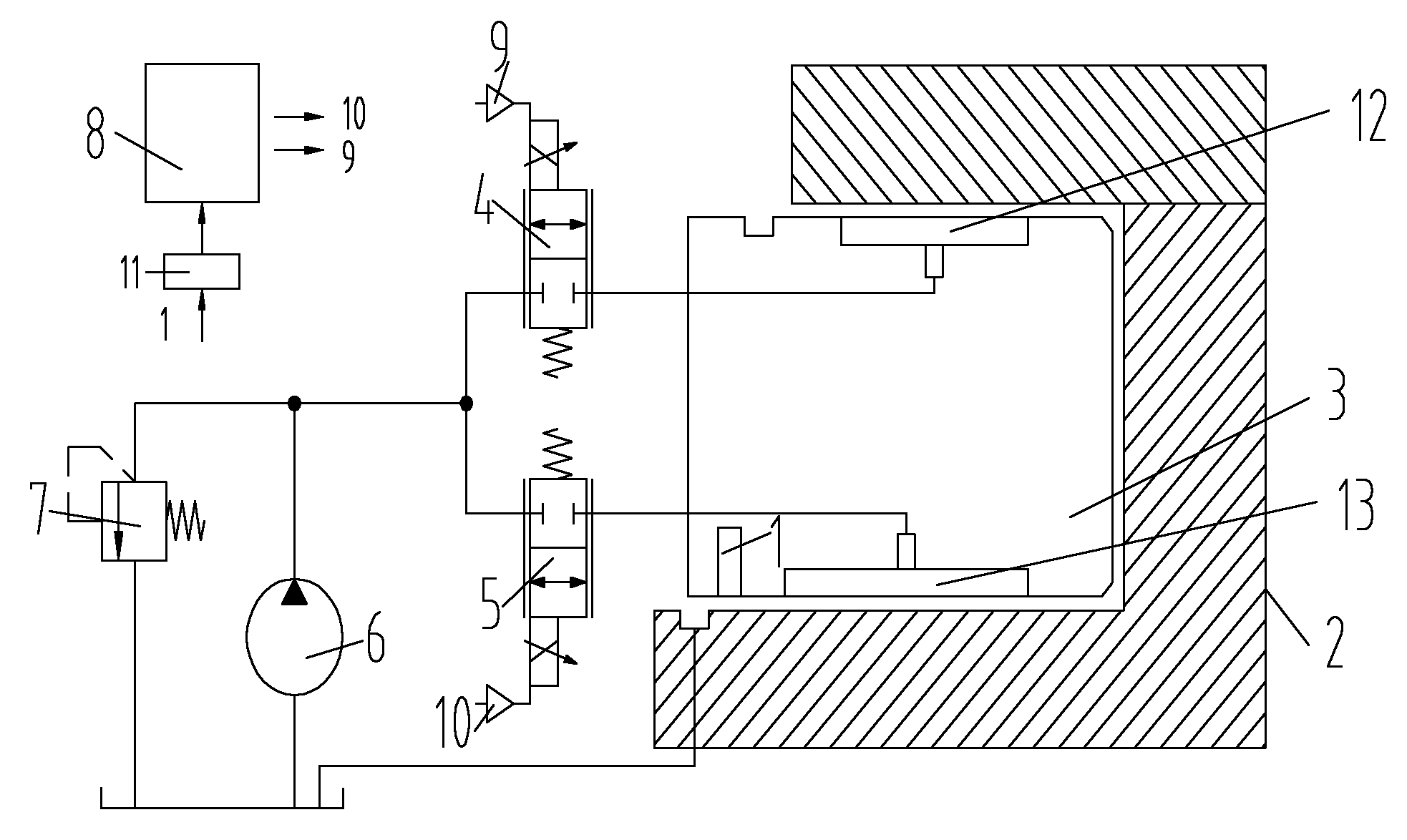

[0015] Such as figure 1 As shown, an active control closed static pressure guide rail includes a guide rail base 2 with a guide rail movable part 3 on the upper part, and a main static pressure chamber 13 and an auxiliary static pressure chamber 12 are arranged on the guide rail movable part 3; The output end of the pump 7 is connected with the input end of the first proportional flow valve 4 and the second proportional flow valve 5 respectively, and the input end of the relief valve 6 is connected with the output end of the hydraulic pump 7, and the hydraulic pump 7 The input end of the overflow valve 6 and the output end of the overflow valve 6 are respectively connected with the oil tank; the output end of the first proportional flow valve 4 is connected with the auxiliary static pressure chamber 12, and the output end of the second proportional f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com