Scooter head assembly jig

A scooter and scooter head technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as low efficiency and poor consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

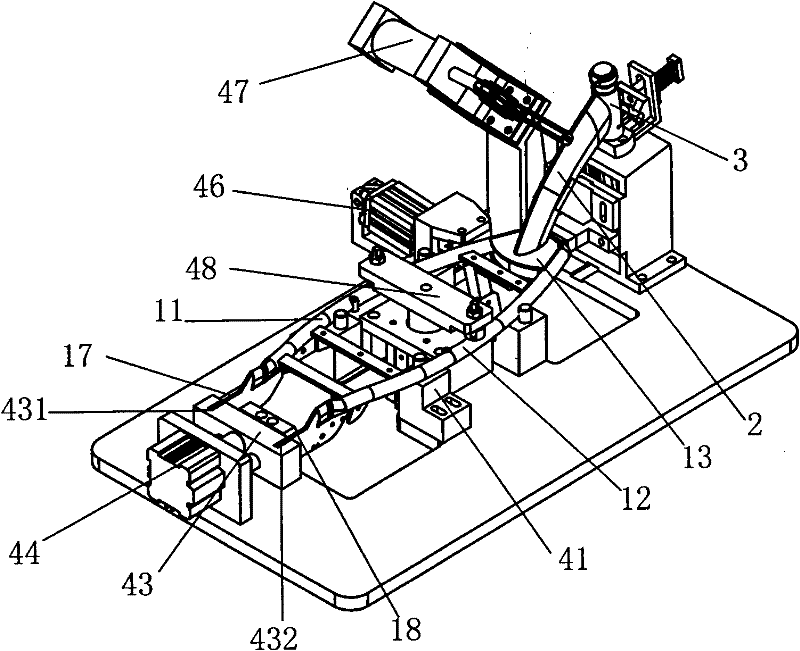

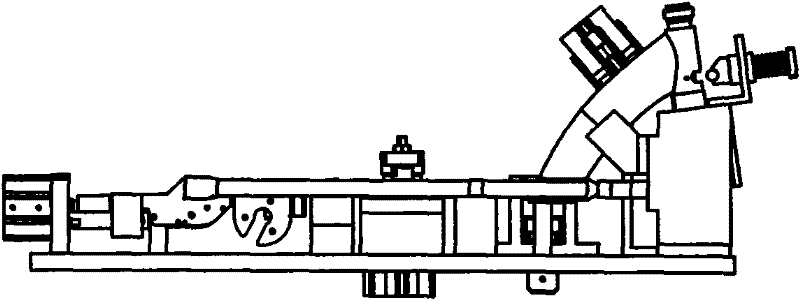

[0035] combine image 3 , Figure 4 , Figure 5 with Image 6 , as further described below:

[0036] A scooter head assembly jig, comprising a first clamping mechanism for fixing the middle part of the frame, a first positioning mechanism for defining the tail of the frame, a second positioning mechanism for defining the lower end of a special-shaped tube 2, and a second positioning mechanism for fixing the special-shaped tube 2 The second clamping mechanism in the middle and the third clamping mechanism that fixes the front pipe 3, wherein:

[0037] 1) The first clamping mechanism includes a frame fixing seat 41 located below a pair of frame elbows 11, 12 on the frame and a first clamp for fixing the pair of frame elbows to the frame fixing seat 41 Clamping cylinder 42, the first clamping cylinder 42 is located in the middle of a pair of frame elbows 11, 12 on the vehicle frame, and the pair of frame elbows 11, 12 is fixed to the vehicle frame by driving a pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com