Preliminary separation process for ferromagnetic ore separation

A strong magnetic and technological technology, applied in the field of beneficiation, can solve problems such as difficulty in achieving stable operation, and achieve the effect of smooth process, safe use and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

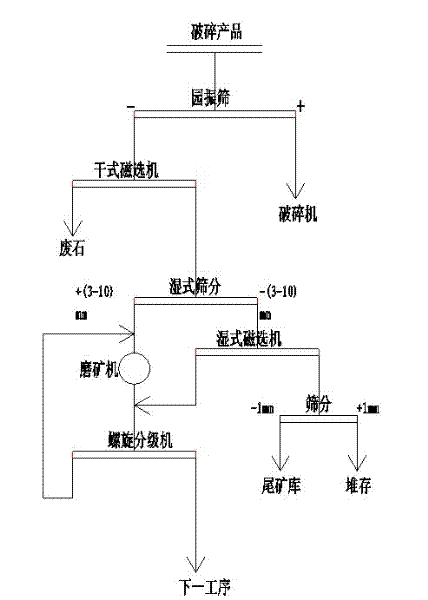

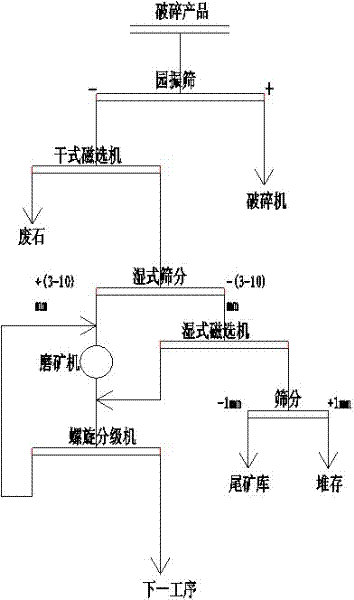

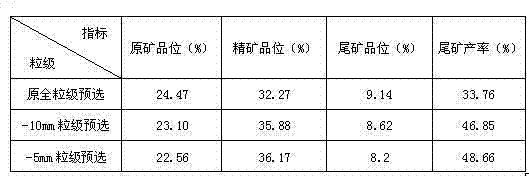

[0017] figure 1 As shown, the pre-selection process of this strong magnetic ore beneficiation adopts the following process steps: (1) Screen the crushed raw ore with a circular vibrating screen, and return the product on the screen to the crusher for re-crushing; the product under the screen directly enters the The dry magnetic separator performs dry magnetic separation, and the dry magnetic separator magnetically selects the dry magnetic separation concentrate and the dry magnetic separation tailings; the dry magnetic separation tailings are transported as waste rock; the dry magnetic separation It is full-size magnetic separation;

[0018] (2) The dry magnetic separation concentrate uses a sieve with a sieve of 3-10mm for wet screening, and the products under the screen enter the wet magnetic separator for wet magnetic separation, and the wet magnetic separation concentrate and wet magnetic separation tailings are magnetically separated ;The sieve product of wet screening e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com